Laminarin from microalgae in plant production and human and animal nutrition

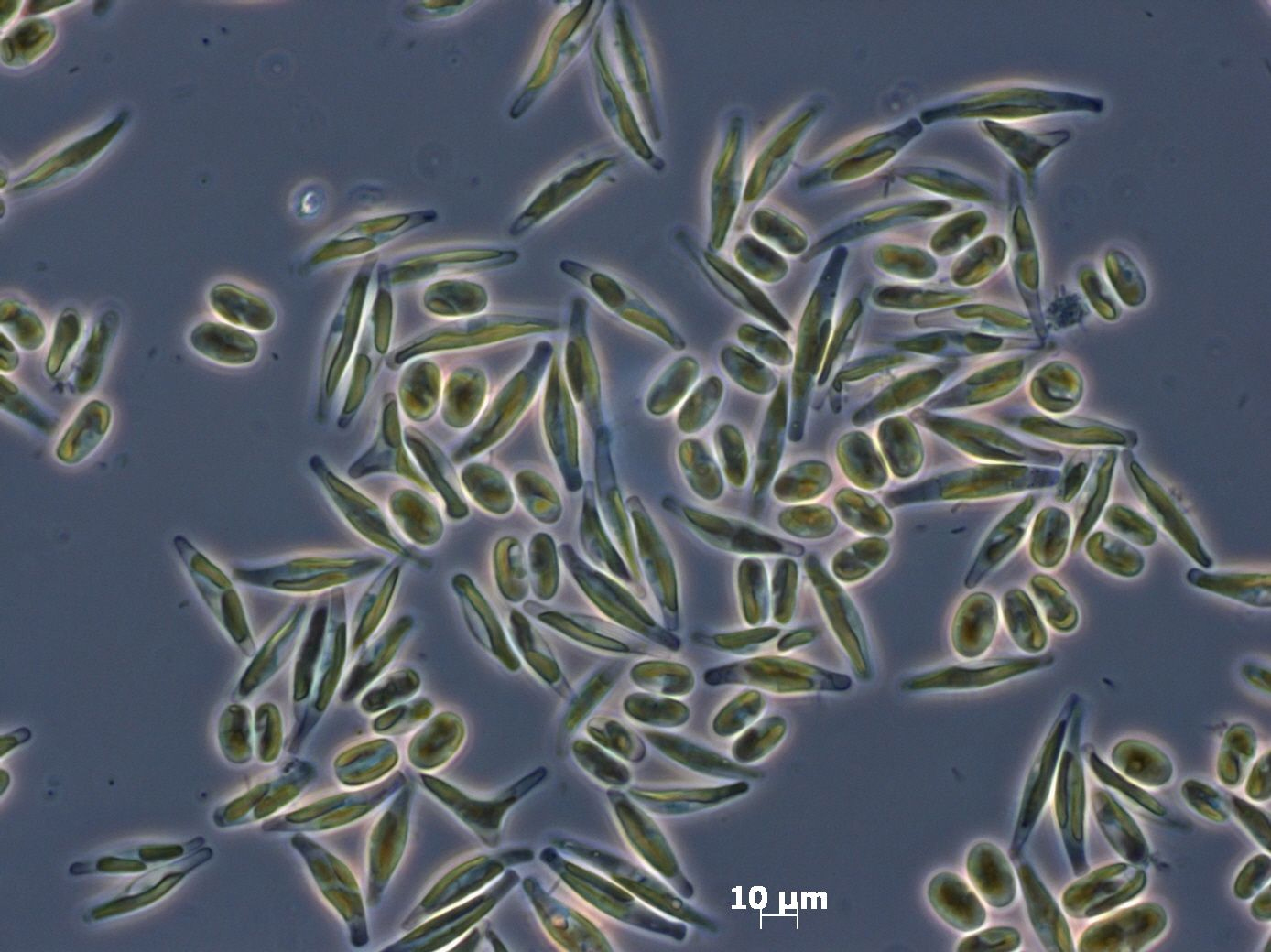

Diatoms (rock algae) use (chryso-)laminarin as energy and carbon reservoirs. The polysaccharide is a 1,3/1,6-b-d-glucan that can be used in the food, animal feed and agricultural sectors. Laminarin can also be found in the cell wall of many fungi, including pathogenic species. Since contact with laminarin induces the immune system of vascular plants, the polysaccharide is suitable as plant strengthener. According to the literature, the application of laminarin can reduce infections with Botrytis cinerea or Plasmopara viticola in grapevines by 55 or 75 percent [1]. Laminarin also has an immunomodulatory effect in vertebrates. The immune system in the digestive tract in particular reacts to the contact with laminarin [2].

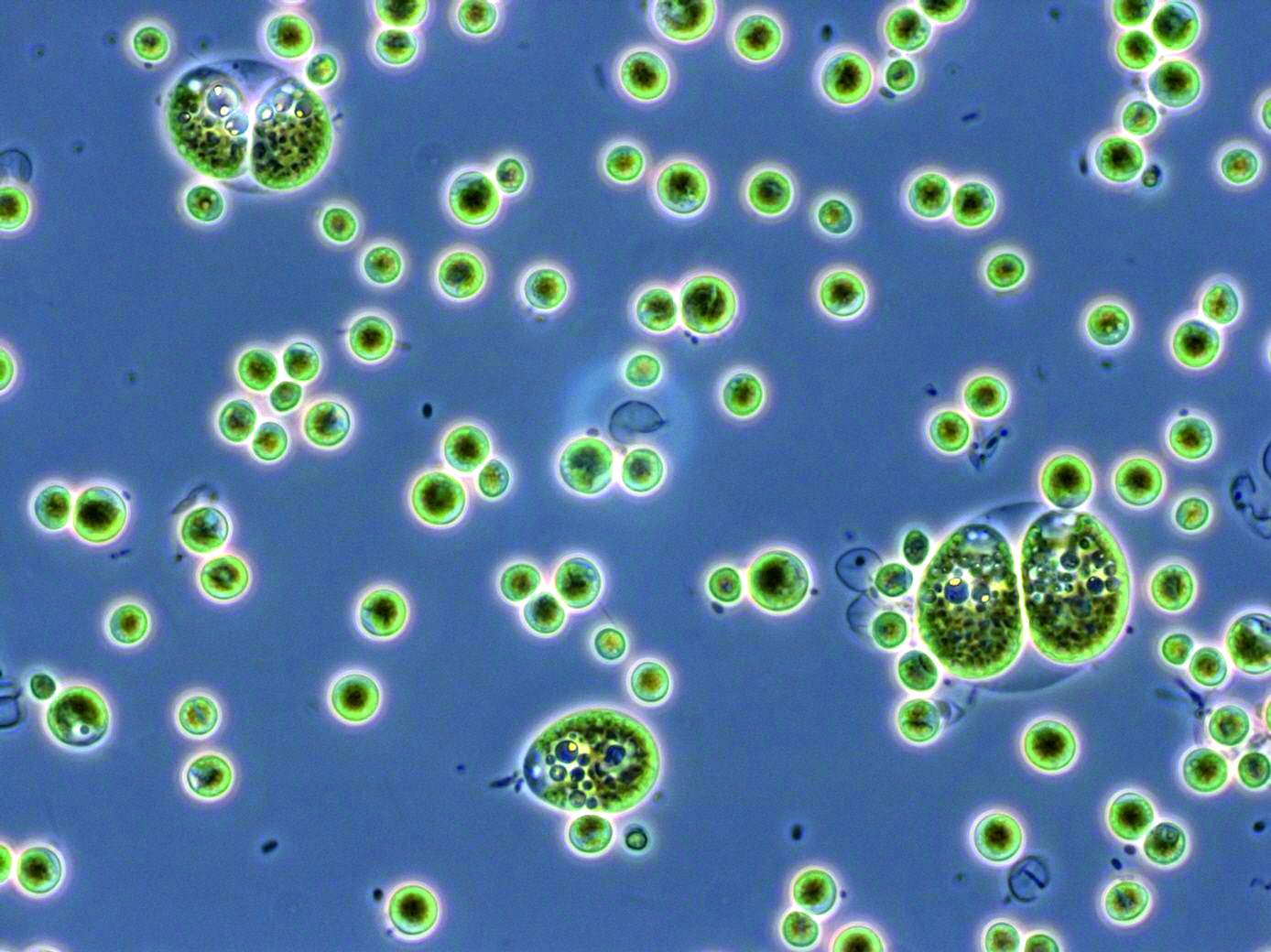

The MIATEST project is examining the use of laminarin as a biostimulant in viticulture in collaboration with the Landesversuchsanstalt für Wein- und Obstbau Baden-Württemberg and its application in nutrition at the Hohenheim University. To this end, Fraunhofer IGB is examining laminarin production strains, developing a two-step production process and producing laminarin-rich algae biomasses for test purposes.

In addition, laminarin is the subject of the EU-funded MAGNIFICENT BBI project, which is examining the provision of ingredients from microalgae for food, feed and cosmetics. The use of laminarin in juvenile fish rearing is currently being investigated.

Literature

[1] Aziz, A. et al. (2003) Laminarin elicits defense responses in grapevine and induces protection against Botrytis cinerea and Plasmopara viticola. Molecular plant-microbe interactions : MPMI 16, 1118–1128

[2] Stuyven E. et al. (2009) Effect of β-glucans on an ETEC infection in piglets. Spec. Issue 8th Int. Vet. Immunol. Symp. 128 (1–3), 60–66

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB