The control of surface properties is of great importance in almost all areas of application. Even in the case of purely mechanical functional components, the question arises as to how they can be bonded, protected against corrosion or decoratively coated. This usually requires several process steps for surface finishing, and oftentimes one problem is that all manufacturing steps of the component leave traces on the surface - for example, residues in the form of release agents may be present in parts or over the entire surface. Already during the search for suitable finishing processes, surface analysis is often required to determine the status quo.

However, even with established processes, the analysis of the surface is always in demand when problems such as failing bonds, peeling coatings, poor electrical conductivity and many more suddenly occur. The question then arises as to the cause in order to eliminate the source of the defect.

In both the establishment of a finishing process and damage analysis, the following imaging and chemical methods are used:

- X-ray photoelectron spectroscopy and imaging (ESCA/XPS) for surface chemistry (the top nanometers are detected),

- Scanning Electron Microscopy (SEM) for topography and morphology, often supplemented with EDX (X-ray microanalysis) for surface chemistry (depth of information about one micrometer),

- Auger electron spectroscopy and imaging (AES), layer composition of the uppermost nanometers, lateral resolution about 0.1 µm.

During the examination of a surface, it is often found that the selected analysis method provides only part of the required information and that another measurement method would be useful. By default, the sample would now have to be removed and fed to the other measuring method - and the previously examined measuring point would have to be found again.

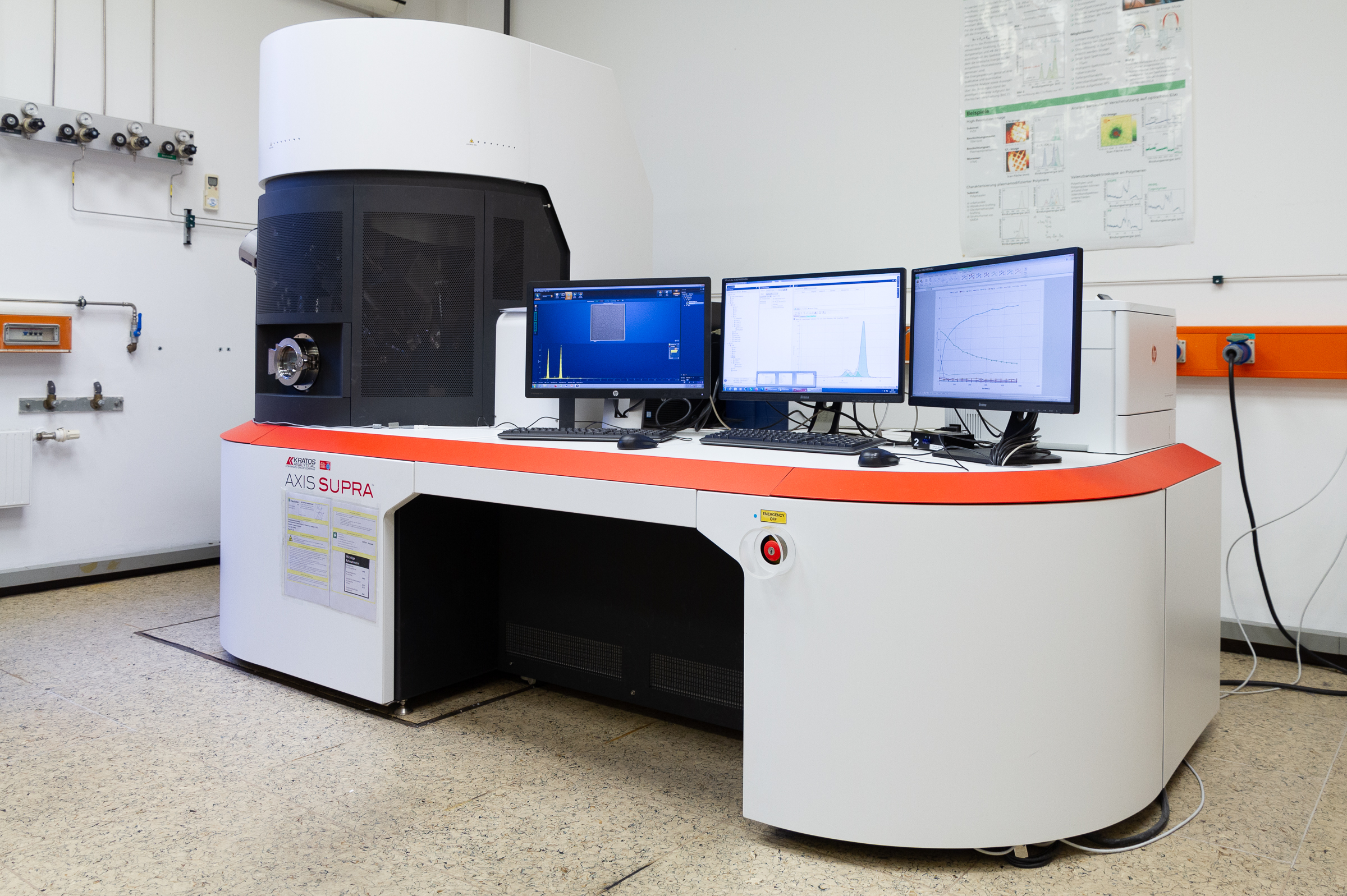

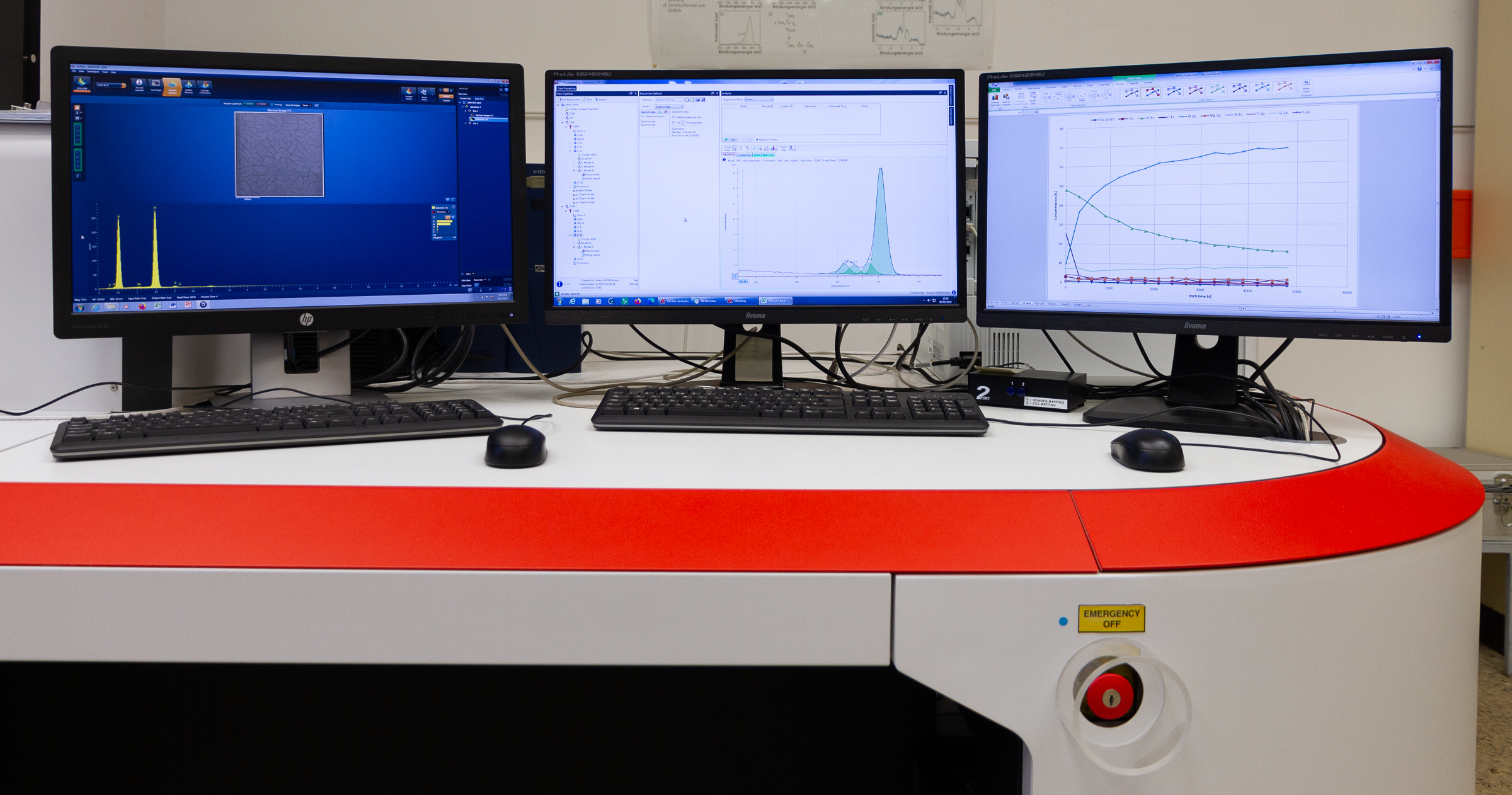

An ESCA (Kratos Axis Supra) is now available at the Fraunhofer IGB, which has been individually expanded and includes SEM-EDX and an AES in addition to an XPS of the latest generation. An ISS (Ion Scattering Spectroscopy for hydrogen detection) is also installed and provides important information about the hydrogen content on the surface, especially for polymer surfaces. The instrument also has an argon ion cluster source for depth profiling. Equipped in this way, even complex layer structures or damaged areas can be examined with high spatial resolution. The methods can of course also be used individually. Scanning Electron Microscopy (SEM) for topography and morphology, often supplemented with EDX (X-ray microanalysis) for surface chemistry (depth of information about one micrometer).

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB