Demand-driven biogas production as a contribution to the energy transition

If biogas is to play an integral part in any future energy system, it is vital to find ways in which it can be produced on a flexible basis and thereby made available on demand. This will also help secure the viability of biogas as a renewable, biogenic source of energy.

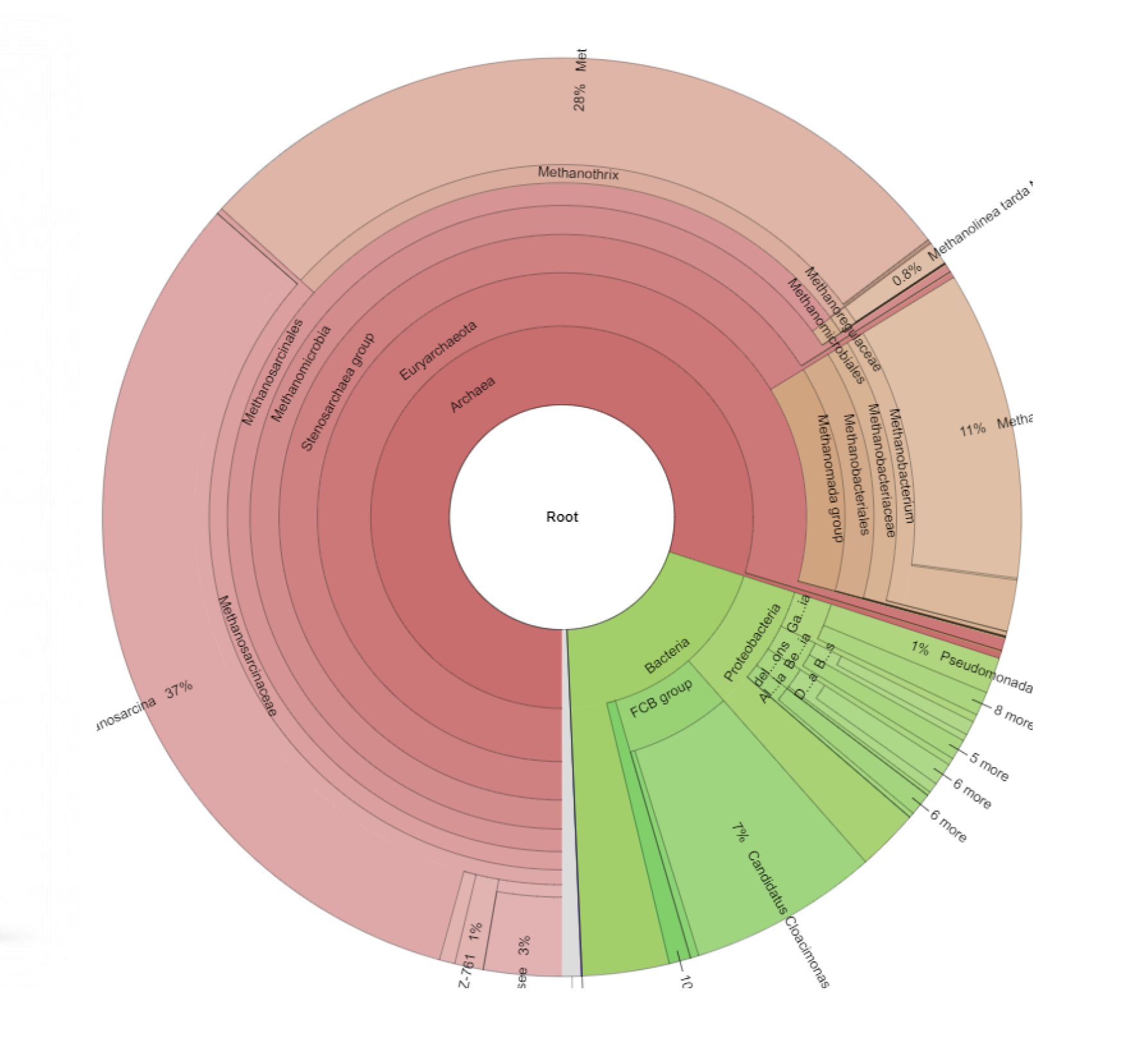

The objective of the NextGenBiogas collaborative research project is to develop a flexible process for the production for biogas on demand for the purposes of flexible power generation. Use of bioengineering methods in a two‑stage process will make it possible to ramp up methane production significantly more quickly than is possible with current technology and research. To achieve this, the anaerobic digestion process must be operated in such a way that the microorganisms involved in methane production can react quickly to changes in operating conditions. Instead of using the substrate or the actual biogas as an energy‑storage medium, the energy is stored in the form of easily convertible organic acids – e.g. acetic acid – which are produced in the first stage of the two‑stage biogas process. In parallel, the microbiome is being characterized by means of next‑generation sequencing.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB