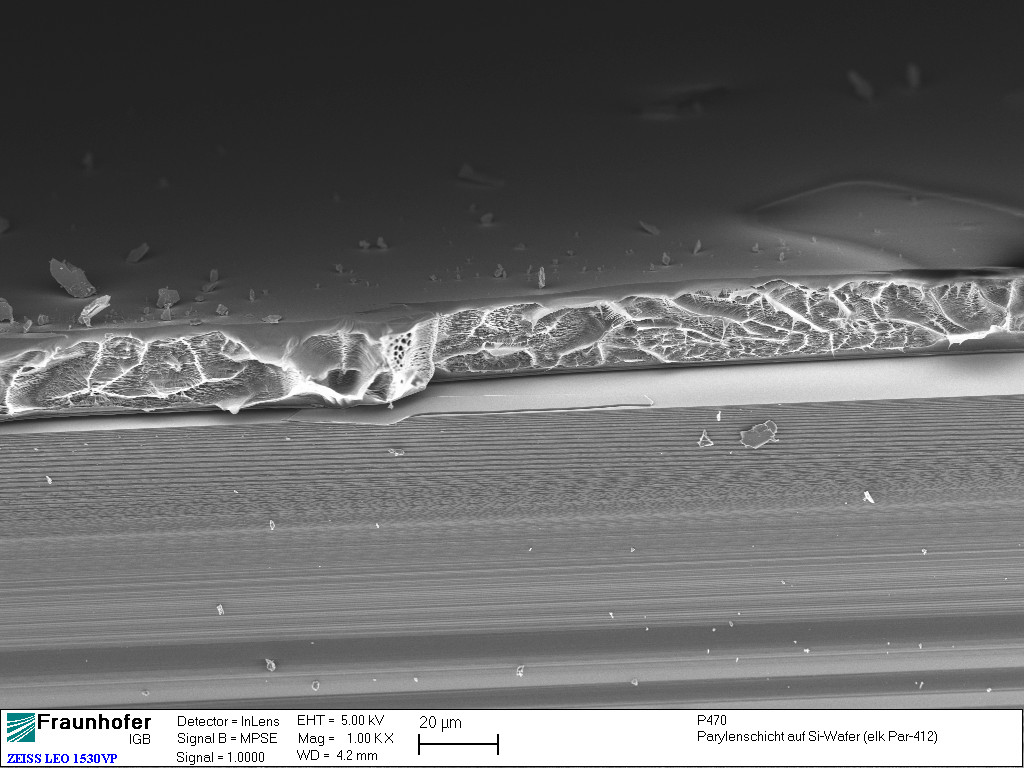

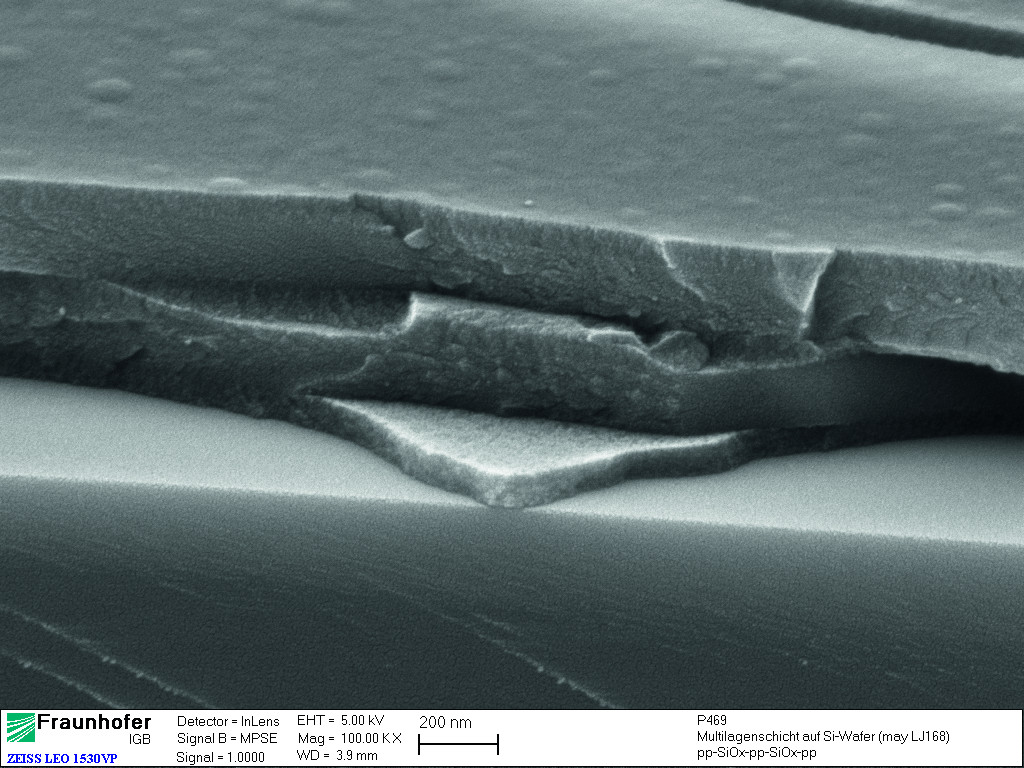

Electronic components in implants must be encapsulated, on the one hand, to ensure that they are protected from the corrosive effect of the environment in the body and, on the other hand, to ensure they do not release any compounds into the tissue. To this end, Fraunhofer IGB has developed biocompatible coatings that are only a few micrometers in thickness and constitute a good barrier to metal ions and water, within the scope of the Fraunhofer Lighthouse Project ”Theranostic implants”. The excellent barrier effect and mechanical stability is achieved here through multiple layers of inorganic and organic coating, with high levels of cohesion in bonding between the layers.

Barrier coatings for the biocompatible encapsulation of electronic implants

Challenge: Protection of electronics and tissue

from the corrosive effectsIn order to ensure that implanted electronic devices can reliably fulfil their function in the longer term, they must be protected from the corrosive effects of the environment in the body. Conversely, the surrounding tissue must not be harmed by compounds released by the electronic device or react with the development of fibrous tissue. Metal or glass housing is currently used which, however, is limited in relation to its potential for miniaturization and cost reduction.

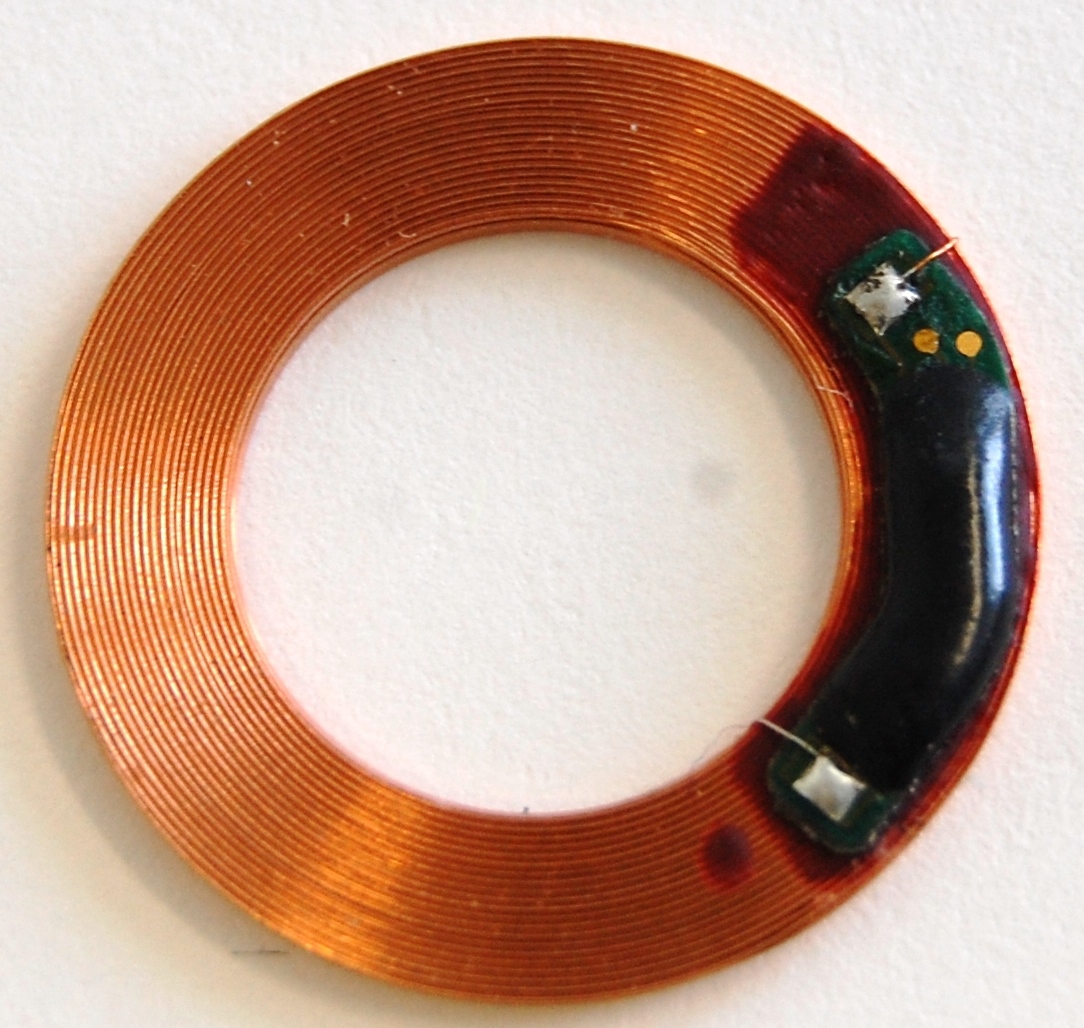

To demonstrate its feasibility, Fraunhofer IGB has produced a barrier coating, which constitutes an effective barrier against metal ions and water, on a circular electronic implant component that contains copper and nickel. The demonstrator remained functional after six months storage in a physiological medium and no copper or nickel ions were released.

Excellent barrier effect and mechanical stability

The new approach to this problem involves multiple layers of inorganic and organic coatings that jointly produce a barrier coating that is mechanically more stable and more effective. The required biocompatibility was considered in the choice of materials. The barrier coatings were produced using PECVD and CVD methods and are composed of SiOx, silicone-like and parylene-C coating, with a total thickness of around 20 micrometers. Factors that are to decisive for good barrier efficacy are high levels of cohesion in the bonding between the layers and a form-fit coating. The coatings that have been developed can be applied to a variety of geometric shapes and will thus facilitate the development of new miniaturized implants.

Project information

Project title

Fraunhofer Lighthouse Project "Theranostic Implants"

Project duration

June 2014 – May 2018

Project partners

- Fraunhofer Institute for Biomedical Engineering IBMT

- Fraunhofer Institute for Applied Polymer Research IAP

- Fraunhofer Institute for Electronic Nano Systems ENAS

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

- Fraunhofer Institute for Integrated Circuits IIS

- Fraunhofer Institute for Ceramic Technologies and Systems IKTS

- Fraunhofer Institute for Microelectronic Circuits and Systems IMS

- Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP

- Fraunhofer Institute for Photonic Microsystems IPMS

- Fraunhofer Institute for Production Technology IPT

- Fraunhofer Institute for Machine Tools and Forming Technology IWU

- Fraunhofer Institute for Cell Therapy and Immunology IZI

Funding

The Fraunhofer-Gesellschaft intends to strengthen Germany as a center for commerce by rapidly transforming original scientific ideas into marketable products through the Lighthouse Project initiative.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB