The reuse of nutrient-rich wastewater is limited to direct, regional local use. If this is not possible, also due to legal requirements, the nutrients phosphorus and nitrogen contained in the wastewater can be recovered in solid, transportable form as fertilizers – and create the basis for a cycle-oriented agriculture.

The harvesting of plants removes nutrients from the soil, which in today's modern agriculture are primarily balanced by synthetic fertilizers. However, deposits of raw phosphates are increasingly contaminated with heavy metals. And the industrial production of nitrogen fertilizers using the Haber-Bosch process consumes enormous amounts of energy: About two percent of the world's primary energy production and five percent of the world's natural gas consumption are caused by nitrogen fertilizer production alone.

The nutrients stored in the plant are not really lost, but end up in biowaste, liquid manure and fermentation residues as well as in wastewater via the food chain. “If it is possible to close the nutrient cycle by recovering the nutrients from these waste streams and recycling them into fertilizers, natural raw material reserves and fossil energy sources can be protected,“ according to Dr. Iosif Mariakakis, Manager of the Nutrient Management Group at Fraunhofer IGB.

It is estimated that 4.3 million tonnes of phosphorus per year are lost worldwide through the sewage system alone. “With our ePhos® process, we have developed an electrochemical process that allows nitrogen and phosphorus to be precipitated as Magnesium-Ammonium-Phosphate (struvite) from municipal wastewater without any addition of salts or alkalies,” according to the IGB expert. The energy requirement is low and can be supplied entirely from renewable sources. Struvite is a high-quality long-term fertilizer for agriculture and can be directly absorbed by the plants.

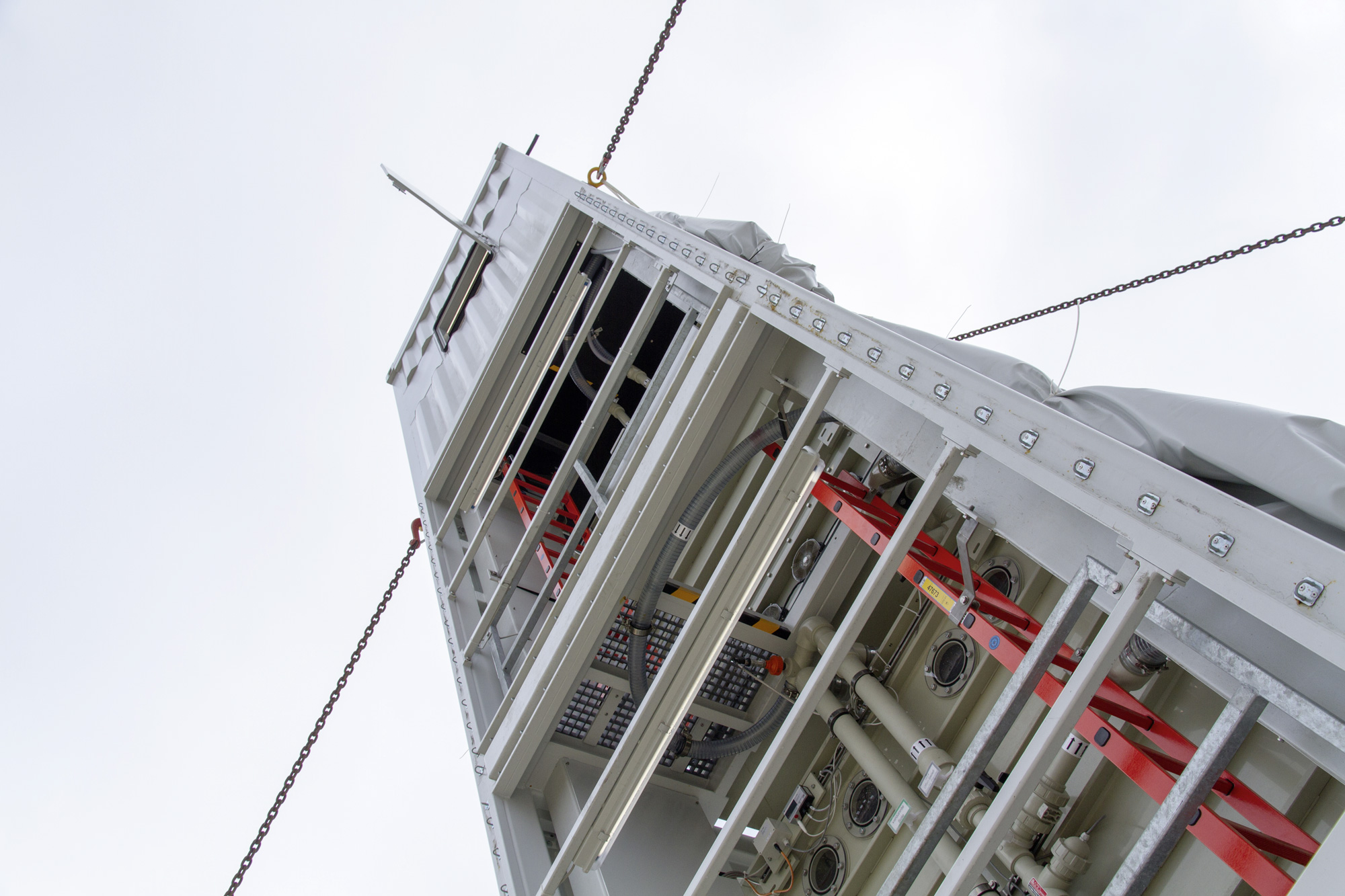

Within the scope of various projects, IGB was also able to develop a concept for recovering phosphorus as fertilizer salt from liquid manure. In a mobile, fully automated pilot plant with a throughput of one cubic meter of raw slurry per hour, more than 90 percent of the phosphorus can be separated from slurry, precipitated and crystallized (see p. 75). The combination of the precipitation step with a low-energy solid-liquid separation also produces a nutrient-poor organic fraction, which can be used as a soil conditioner, in particular to increase the moisture capacity in the soil. The process can also be used for the recovery of phosphorus from fermentation residues produced in agricultural biogas plants.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB