Removing pollutants and contaminants from wastewater

The Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB and its European partners have developed several effective processes for eliminating persistent pollutants from wastewater. Some of these processes generate reactive species which can be used to purify even highly polluted landfill leachate while another can also remove selected pollutants which are present in very small quantities with polymer adsorber particles.

Biological stages in wastewater treatment plants are not able to remove substances such as drugs, found in the wastewater of medical centers, or halogenated compounds and cyanides from industrial wastewater. This is why antibiotics and hormonally active substances such as bisphenol A from plastics manufacturing have already accumulated in the environment and can be traced in ground water and even in some samples of drinking water. Such persistent pollutants require a special purifying treatment to remove them from wastewater. Our tests have shown that oxidative processes with hydrogen peroxide or ozone as the oxidizing agent are especially effective.

It is usually necessary to adapt or combine various processes in order to be able to degrade the many different components present in industrial wastewater in an effective and efficient manner. The Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB runs a pilot plant in Stuttgart for testing standard processes either individually or in any desired combination. The IGB has added two new methods which generate reactive species, especially hydroxyl radicals, efficiently. Hydroxyl radicals oxidize pollutants into smaller, more degradable organic molecules or mineralize them completely to carbon dioxide. In the first method, reactive molecules are generated electrochemically in a combined anode/cathode process and in the second by means of atmospheric pressure plasma. Neither method requires the addition of additives.

Oxidative electrochemical treatment of landfill leachate

Within the CleanLeachate project funded by the EU (grant agreement no 262335), www.cleanleachate.eu), the Fraunhofer IGB has developed an oxidative process which does not require additives and which is, thanks to its electrochemical operating principal, suitable for treating extremely turbid wastewaters. A consortium of six partners from five European countries is currently treating highly polluted leachate from landfill sites with a combined anode/cathode process, in which a membrane separates an electrolytic cell into two separate chemical reaction areas. Top priority was given to choosing the most suitable electrode material, especially for the anodes, where the hydroxyl radicals are generated as reactive species when voltage is applied. The polluted water flows past the anode where it is oxidized and is then pumped to the cathode where the components are reduced.

The treatment is now being tested in continuous operation on a landfill site in Czechia. This has lead to improvements such as the lowering of the chemical oxygen demand and the overall nitrogen concentrations to below legal limits and the fulfilment of wastewater regulations. To make the process ready for marketing, a prototype was automated and made portable to test further types of wastewater, while gathering experience and reliable data for further optimization steps.

Open plasma processes for water purification

Another new approach for purifying water involves the use of an atmospheric pressure plasma. A plasma is an ionized gas containing not only ions and electrons but also chemical radicals and electronically excited particles as well as short wave radiation. Plasma can be ignited by means of an electromagnetic field e.g. by applying high voltage. The plasma glow is characteristic and can be seen in the fluorescent lamps of neon signs used for advertising purposes. In a technical sense, plasma processes have already been used specifically for modifying and cleaning surfaces for a long time now.

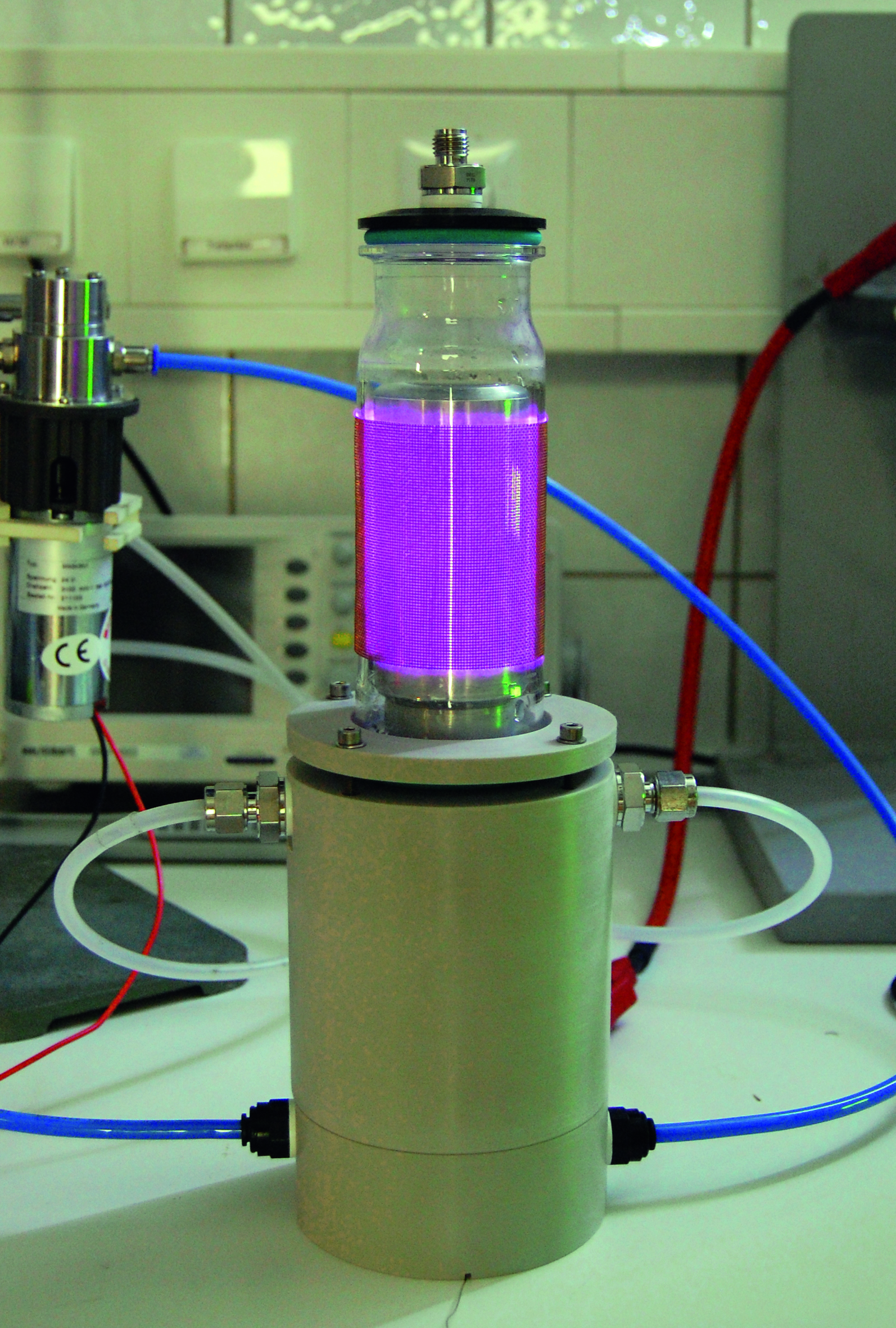

This principle is currently being applied by the partners of a joint water plasma project, funded by the EU, entitled "Water decontamination technology for the removal of recalcitrant xenobiotic compounds based on atmospheric plasma technology", grant agreement no. 262033, www.waterplasma.eu, in which a plasma is used for purifying water in an oxidative process. The result is a plasma reactor in which the reactive species formed in the plasma can be transferred directly to the contaminated water. The reactor is "open" so that the plasma is in direct contact with a flowing water film. The plasma reactor is designed in such a way that a plasma can be ignited and maintained between a grounded electrode in the form of a stainless steel cylinder within the reactor and a copper network acting as high voltage electrode. To do so, high voltage is applied. The copper network is on a glass cylinder which acts as a dielectrical barrier, also shielding the reactor to the outside. Polluted water is pumped upwards through the stainless steel cylinder in the center of the plasma reactor. When the water flows down the outer surface of the cylinder, it passes through the plasma zone between the stainless steel cylinder and the copper network where the pollutants are oxidized.

In laboratory experiments, Fraunhofer researchers were able to decolor a methylene blue solution completely within a few minutes. Cyanide was also broken down effectively by 90 percent within only 2 minutes. Based on such promising results, the process is now being tested on a larger scale. One of the project partners is working with a demonstrator which can purify 240 liters of contaminated water in one hour. The results will be used to continually optimize the design of the reactor and its process controls. The ultimate aim is to bring the reactor to market together with further partners from industry. The open plasma process has a high potential due to the fact that there is no barrier between the plasma, where the oxidative radicals are formed, and the contaminated water.

Removing trace substances with selective adsorber particles

Pollutants can also be removed effectively from wastewater with selective adsorbers. An adsorption stage is particularly effective when pollutants are strongly diluted, present in low concentrations or highly specific. The process is also advisable when a wastewater component is degraded to a toxic metabolite in biological purification stages. In such cases, it could be better to remove the substance selectively by pre-treating the wastewater before it reaches the wastewater plant.

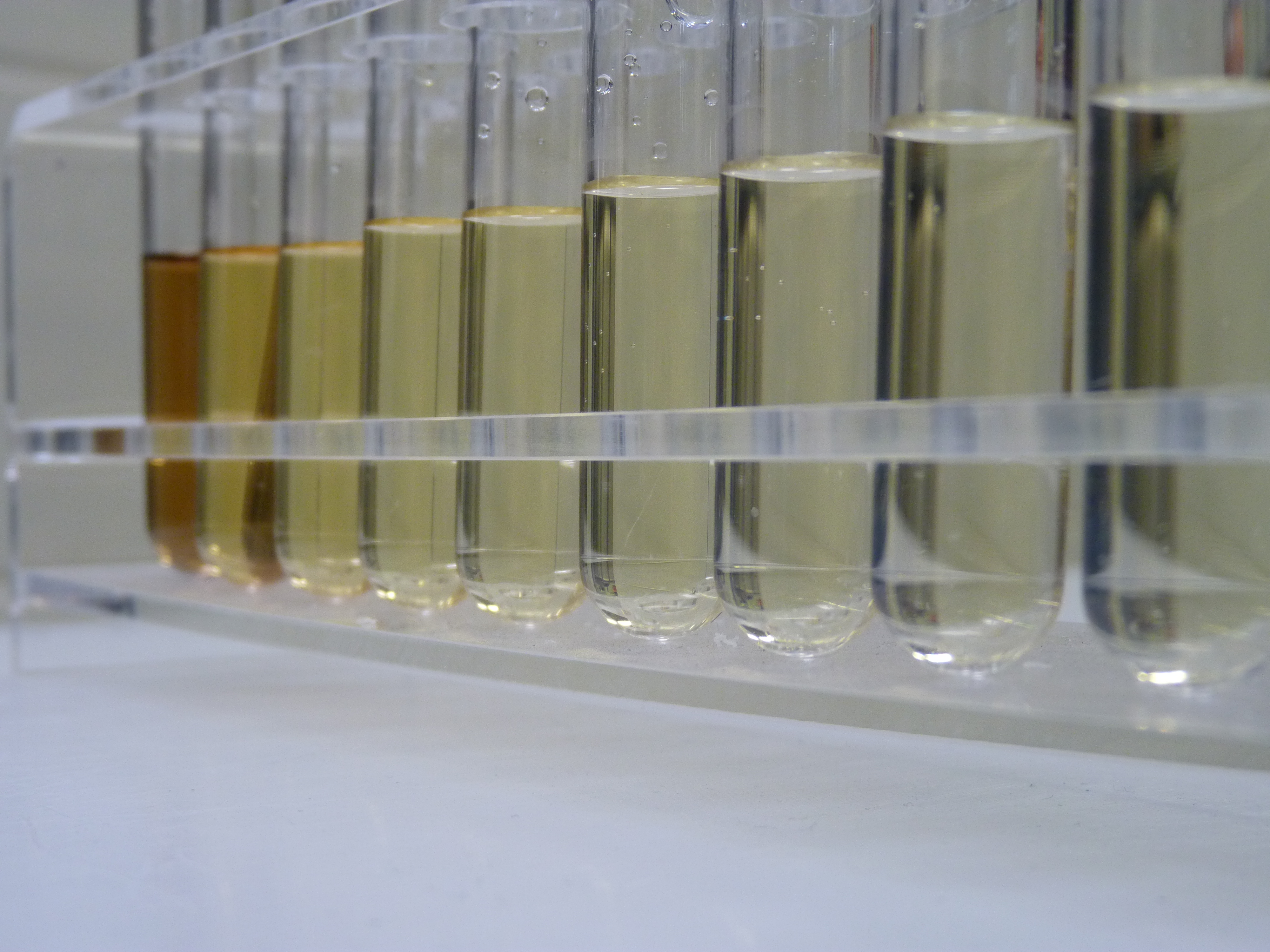

To this aim, the Fraunhofer IGB has developed a single stage, cost-effective process for producing polymer adsorber particles. In NANOCYTES®, our patented process, functional monomers are transformed into small nanoscopically sized polymeric adsorber particles, so-called specific polymeric adsorber particles (SPA), with a cross-linking agent. The selectivity of the adsorber particles can be increased by adding the target molecules to be removed from the water to the mixture. The trick works like this: once the monomers have been polymerized, the target molecules can be removed from the adsorber particles. They leave behind a kind of "imprint" which adsorbs the target pollutants.

These particles possess a high specific surface area and the particle surface is easily accessible without limitations. In addition this approach offers a large flexibility in the design of the surface chemical properties and the adsorption behavior. A large variety of different monomers (mono-, bi- and trifunctional) can be used. They are selected on the basis of physico-chemical properties such as solubility, miscibility and non-covalent interactions with the target molecules. The particle properties can therefore be tailor-made for special separation problems.

Fraunhofer researchers have been able to remove bisphenol A and penicillin G selectively from wastewater. The adsorber particles are chemically and thermically stable and can be used for a wide range of applications e.g. as a layer in a composite membrane or as a matrix on packing materials. Once the pollutants have been adsorbed, the adsorber particles can be regenerated and re-used. An adsorption column is available at the Fraunhofer IGB for research experiments.

Systems solutions for water supply and water treatment

These innovative processes for water treatment complement the Fraunhofer IGB's portfolio in the fields of water purification and water treatment. Together with further processes for water treatment and recovering wastewater components as energy and fertilizing salts, the Fraunhofer IGB is steadily optimizing wastewater treatment plants and improving DEUS 21, a system for the semi-decentralized purification of household wastewater.

Reprints free of charge. A voucher copy is appreciated in case of publication.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB