Scaling of the fractionation process to the pilot plant

The work at the Fraunhofer CBP focused on the scaling of the fractionation process to the pilot scale. The basic questions concerning the process specifications were worked on in joint preliminary work with the project partners. The plant was designed and planned in detail on the basis of these results.

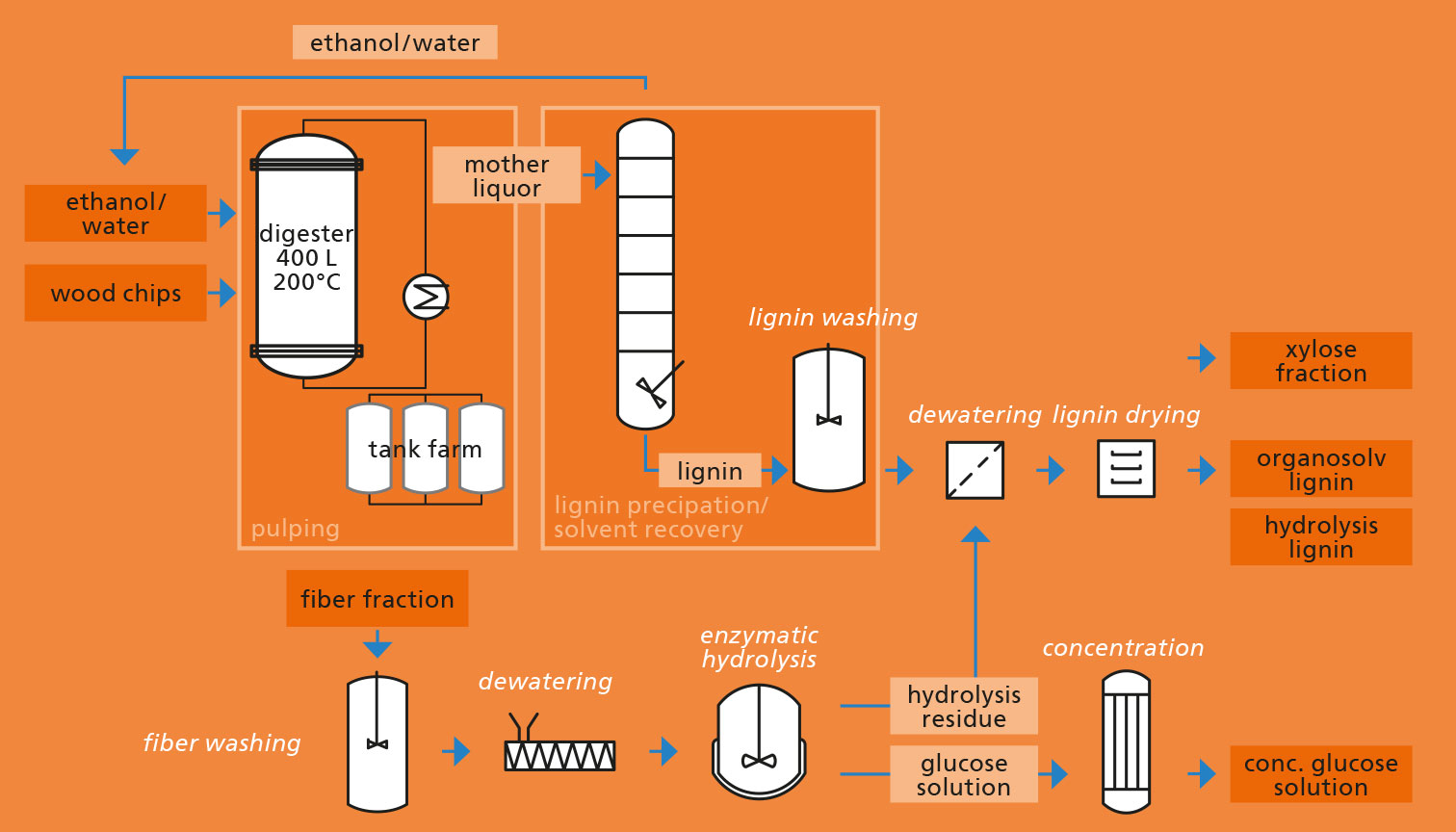

The pilot plant comprises a large number of individual process steps for the production of concentrated sugar solutions and lignin powder obtained from wood chips. Up to 70 kg of wood (oven dry weight) can be processed in one batch. The plant was designed in such a way that the material and energy cycles are closed. The simplified diagram of the plant in Fig. 2 shows that the wood is first of all digested in a 400‑liter reactor at up to 200 °C; here lignin and hemicelluloses are solubilized in an ethanol‑water mixture. The additional tanks and heat exchangers of the “tank farm” permit a fractional washing of the material under reaction conditions and the recovery of energy during the pulping process. From the pulping liquor enriched with lignin and hemicelluloses lignin is precipitated by adding water or distilling the ethanol; it is then filtered off and, after washing, dried. The ethanol used is entirely recovered by distillation from the filtrate and the hemicellulose sugars remain as an aqueous solution. The solid fibrous residue of the pulping process is disintegrated and washed, dewatered, enzymes are added and then, in stirred reactors specially designed at the Fraunhofer IGB, it is saccharified with a high concentration of the pulp. After a filtration step a glucose solution is obtained which is concentrated into a sirup to stabilize it.

The pilot plant was built at the same time as the CBP was constructed. The pilot plant was successfully put into operation in spring 2013. Since then we have been further optimizing the individual processes as well as the overall process. Additionally, complete mass balances were recorded and product samples on the kilogram scale were distributed to the project partners so that they could carry out technical application tests.

Fraunhofer Center for Chemical-Biotechnological Processes CBP

Fraunhofer Center for Chemical-Biotechnological Processes CBP