Microalgae offer a high protein, carbohydrate or lipid content, depending on growth conditions. Fast growing microalgae have a high protein content with a favorable distribution of essential amino acids. Many microalgae have the ability to produce substantial amounts (e.g. 20 – 70 percent dry cell weight) of triacylglycerols (TAGs) or starch as a storage product when under stress and growing slowly, and simultaneously high light intensities are available.

In screening tests at the Fraunhofer IGB various algae were tested for their ability to produce storage lipids under the conditions of a flat panel airlift (FPA) reactor. Lipid content increased up to 70 percent of dry cell weight and starch contents up to 60 percent are achievable. Under these conditions mainly monounsaturated fatty acids with 16 and 18 carbons were synthesized. Lipid productivity was not specific for a certain strain but depended largely on the light intensity per cell.

Starch can be used as sugar feedstock for miscellaneous biotechnological processes for biofuels or biobased chemicals. The Fraunhofer IGB has developed a two-stage process for production of starch-rich microalgae, which has been established under outdoor conditions as well as scaled up to pilot scale in the range of 100 kg dry biomass.

Energetic use of microalgae biomass

Sustainability by recycling of nutrients

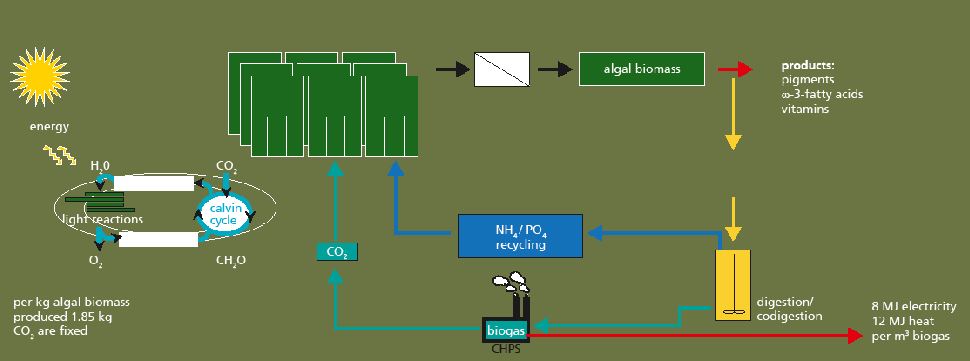

Fraunhofer IGB is developing sustainable, resource-efficient and ecologically friendly production processes for the production of valuable products and the energetic use of microalgae combining the use of flue gas from combustion processes or offgas from biotechnological fermentations like bioethanol as the carbon source (combined heat and power stations with biogas or natural gas). Our intention first is to recover valuable products from microalgae followed by digestion of the residual biomass to biogas. Carbon dioxide is recycled to the algal cultivation process. For a positive net energy balance the use of waste gas as the carbon source is a basic requirement for photoautotrophic microalgae biomass production. Additionally, recycling of nitrogen and phosphorous from anaerobic digestion effluents is possible.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB