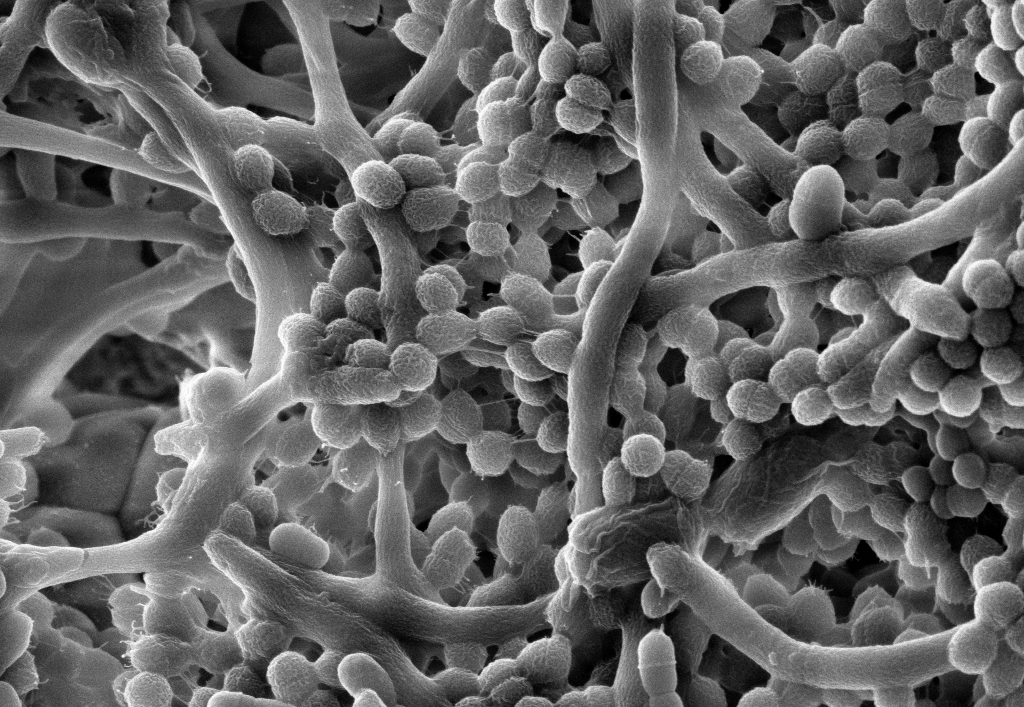

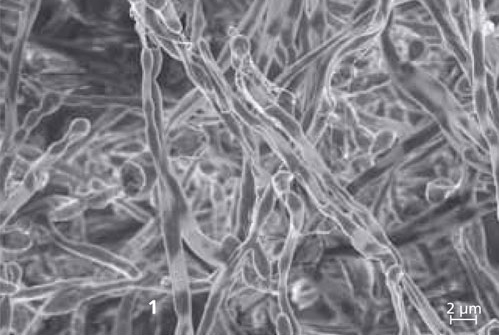

Microorganisms on surfaces occur widely in nature. Bacteria, fungi and algae have adapted to growth on various surfaces and benefit considerably from this way of life, which is adapted to each particular location, for example on stones in a stream, and also in various kinds of piping. Their growth becomes visible to the human eye when biofilms develop excessively. Frequently the microbial growth causes damage to the material or impairs the functioning of technical equipment.

Interactions between microbial cells and surfaces

At Fraunhofer IGB, we have been working on questions in which the interactions between microbial cells and surfaces or the formation of biofilms play a role for several years. On the one hand, we use biofilms by targeted immobilization of microorganisms on a carrier material, for the production of valuable substances or for waste water purification.

On the other hand, we also consider the prevention and control of biofilms – where they are undesirable and cause damage – through our research. For example, we have developed test methods for the investigation of biofilms and are investigating surfaces and components in medical technology, construction, wastewater treatment and hygiene for microbiological contamination.

Examples of damage caused by biofilms are the deterioration of the efficiency of heat exchangers or air-conditioning systems. In the healthcare sector enormous efforts are being made to prevent the growth of biofilms on natural surfaces such as dental material as well as synthetic materials such as implants, catheters or medical devices – also due to high consequential costs in the event of human injury.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB