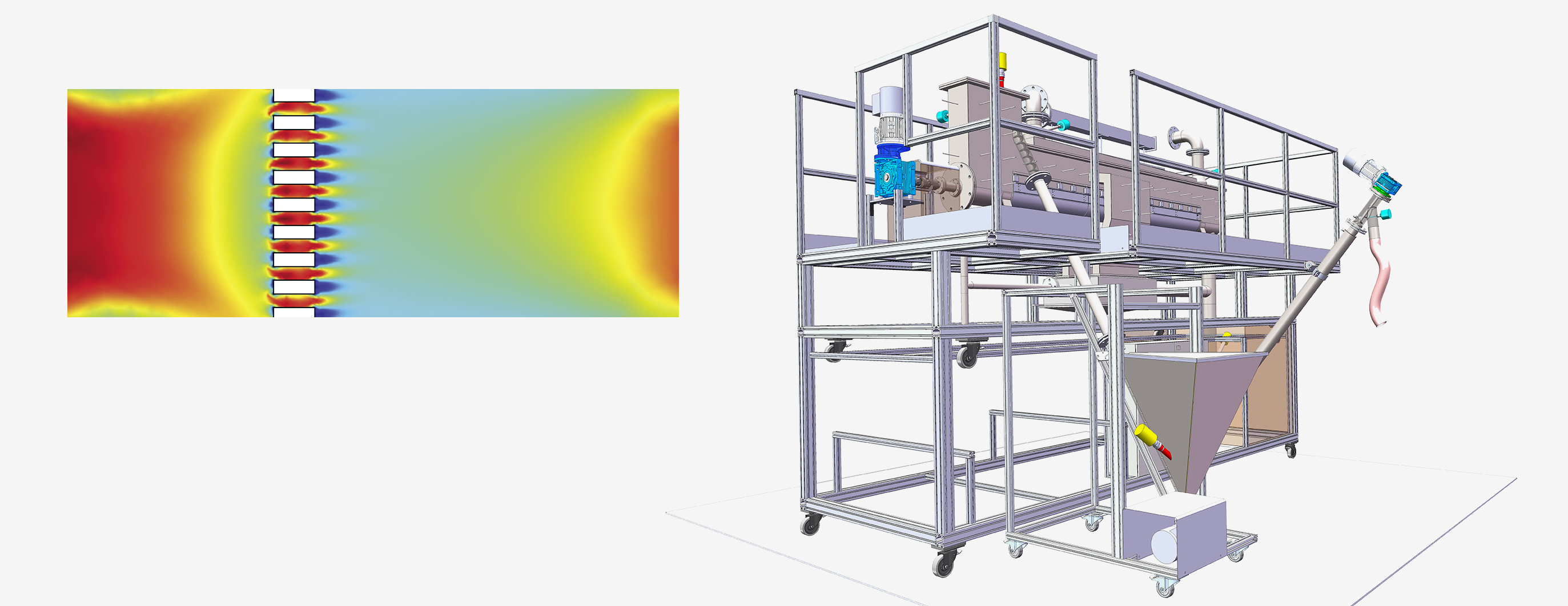

We evaluate the industrial feasibility of new technologies at an early stage and readiness-level and develops concepts for their exploitation. This is done in close cooperation within all research units at the IGB and our industrial partners. In the implementation of innovations we support our partners and industrial customers in the realization, scale-up and plant operation up to technology readiness level (TRL) 9.

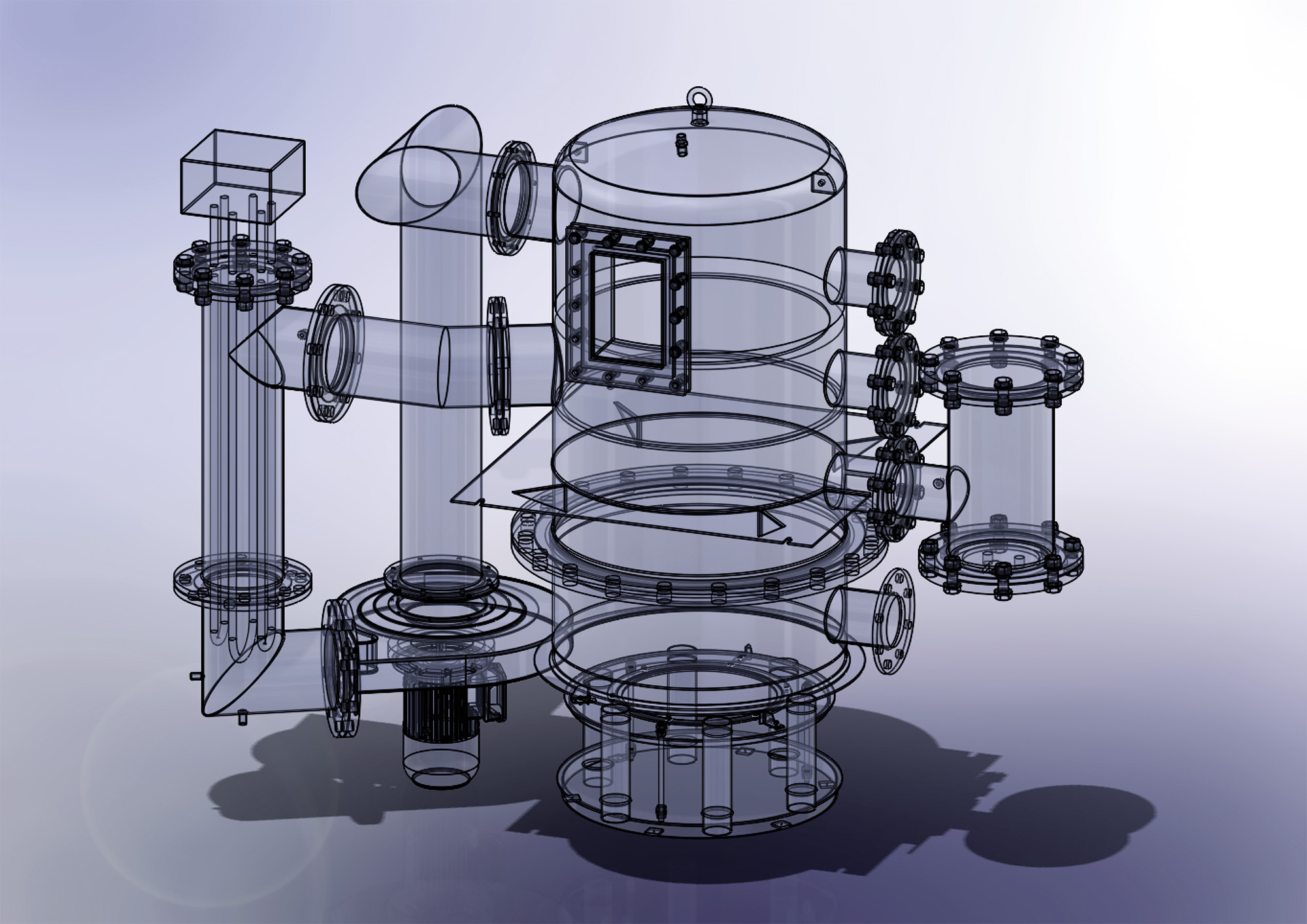

For the technical realization of demonstrators and prototypes, a team of experts in the fields of mechanical, electrical and software engineering provides a comprehensive portfolio of engineering competencies and methods based on the principles of methodical design.

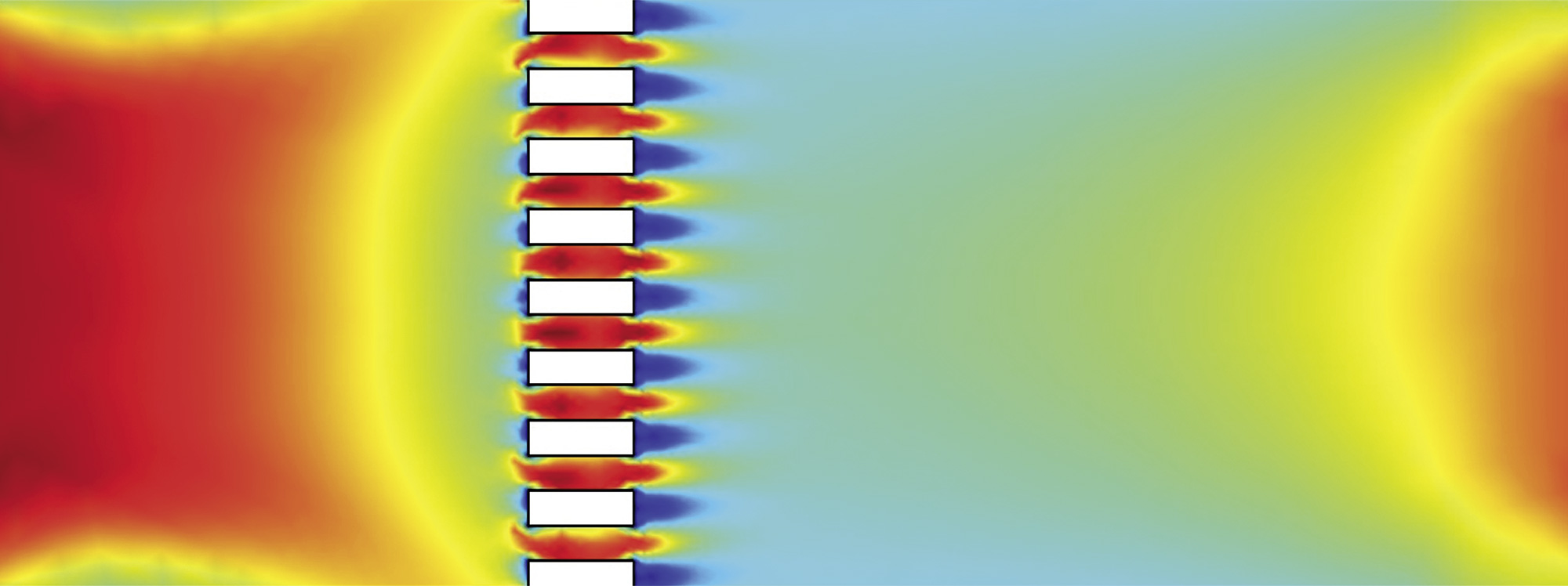

Our services range from the conceptual and detail design of components and systems at early laboratory and demonstration plant scale-up to the construction of pilot and prototype plants for the validation of their industrial suitability as well as their integration into existing plant and process systems. For technologies that were initially developed for a specific application, we also identify further potential uses in other business areas. In this way, we also provide horizontal technology transfer.

Based on our many years of experience and broad expertise, we also provide solutions to many questions relating to the industrial design of technical systems, for example:

- Development methodology: Quality Function Deployment QFD, Value Engineering, Rapid Prototyping, Rapid Product Development

- Hygienic Design, CIP, etc.

- Regulations for certifications: ATEX, FDA, DVGW, etc.

- Initiation and handling of approval procedures (e.g. BImSchG)

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB