Nano- and microstructured coating by means of plasma technology

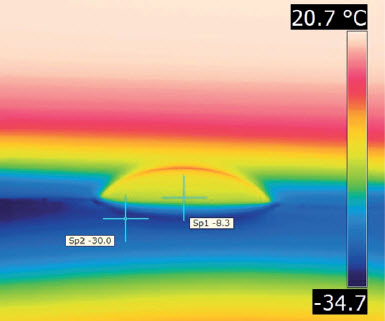

In the "Nanodyn" joint project funded by the Federal Ministry of Education and Research (BMBF), we have developed water-repellent micro- and nanostructured layers, on which water remains liquid even at temperatures below zero degrees. This means that ice formation is largely prevented. The reason: the layers do not provide any crystallization nuclei for the water to freeze on the surface, and it remains in a "supercooled" state. Even when the water freezes, our anti-ice equipment reduces the adhesion of ice by more than 90 percent compared to the uncoated surface. This type of coating can be applied to a variety of surfaces. For this purpose, the surface to be modified is inserted into a vacuum chamber in which a so-called plasma modifies the surface.

Deposition on self-adhesive PU film - anti-ice film

For easy handling, we also attach the structured anti-ice coatings on self-adhesive plastic foils by means of plasma technology. These foils are made of impact-resistant and impact-resistant polyurethane (PU). The components can then simply be laminated with the anti-ice film.

Inkjet printing process

Fraunhofer IGB also works on inkjet printing processes to coat surfaces over a large area and in a structured manner and to adjust the wetting properties according to the customer. The model is the nature of this: using this method, biomimetic surfaces can be generated.

Microstructure by printing process

For the introduction of a microstructure, which also produces anti-ice properties, into the film surfaces, these are modified by embossing processes. By embossing, it is possible to produce topograpies with a large aspect ratio (ratio of a structure to its lateral extent). These structures are then additionally provided with further specific anti-ice equipments in subsequent processes. This may be the above-mentioned passively acting anti-ice coating by means of plasma processes and, on the other hand, actively heatable surface finishes.

Combined coatings

In order to achieve effective active and passive anti-ice equipment, the coatings can also be combined. With this combination, the anti-ice surface functionalization can react intelligently to the changing environmental conditions.

Applications

Anti-ice coatings have many areas of application: apart from aircraft wings, they can also be attached to wind turbines, which in winter freeze or become unbalanced due to ice formation, on solar panels, power lines, building parts, textiles or sports equipment. An application which is easy to apply and can be interchanged at any time could also be offered on refrigerated units or refrigerators.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB