Challenge: Separation of oxygen from air

The separation of oxygen from air is of economic and environmental importance for many large-scale processes. In recent years, mixed-conducting perovskites have increasingly come into focus as membrane materials for the selective separation of oxygen from gas mixtures.

New perovskite membrane combines excellent material properties with effective specific membrane surface area

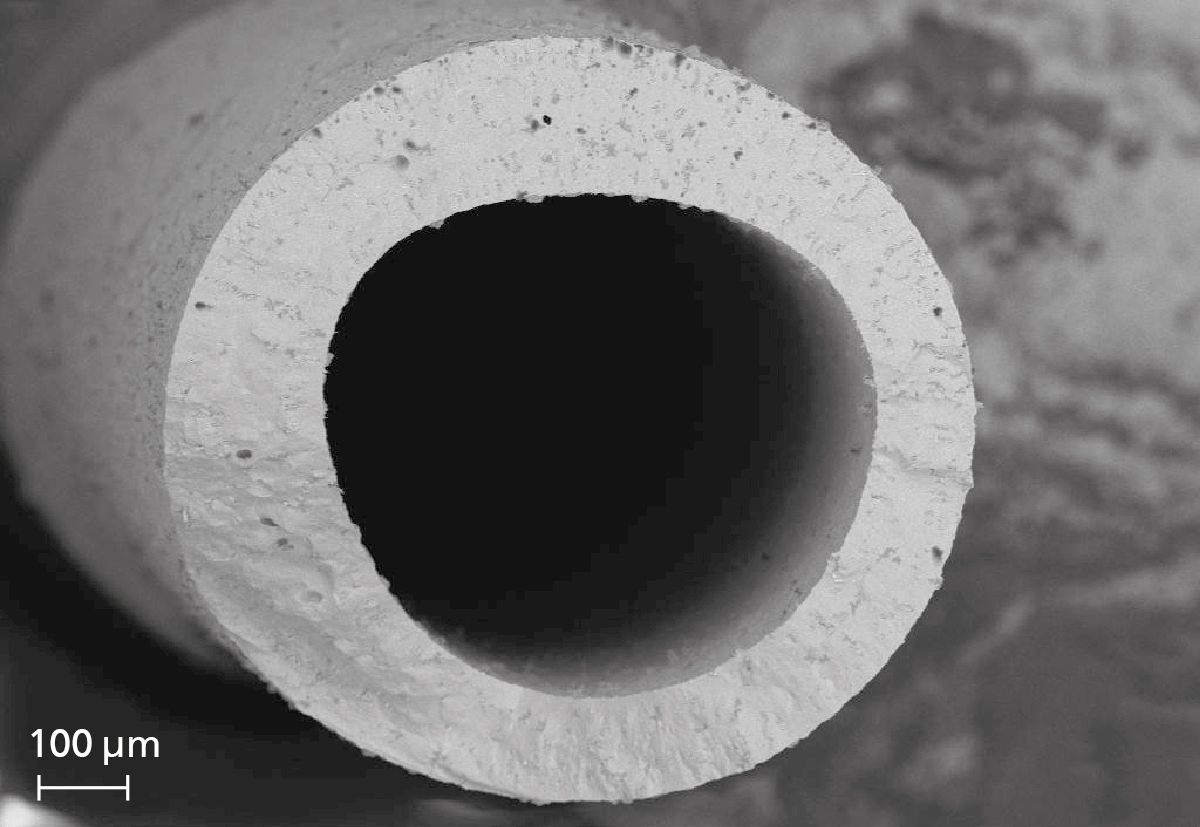

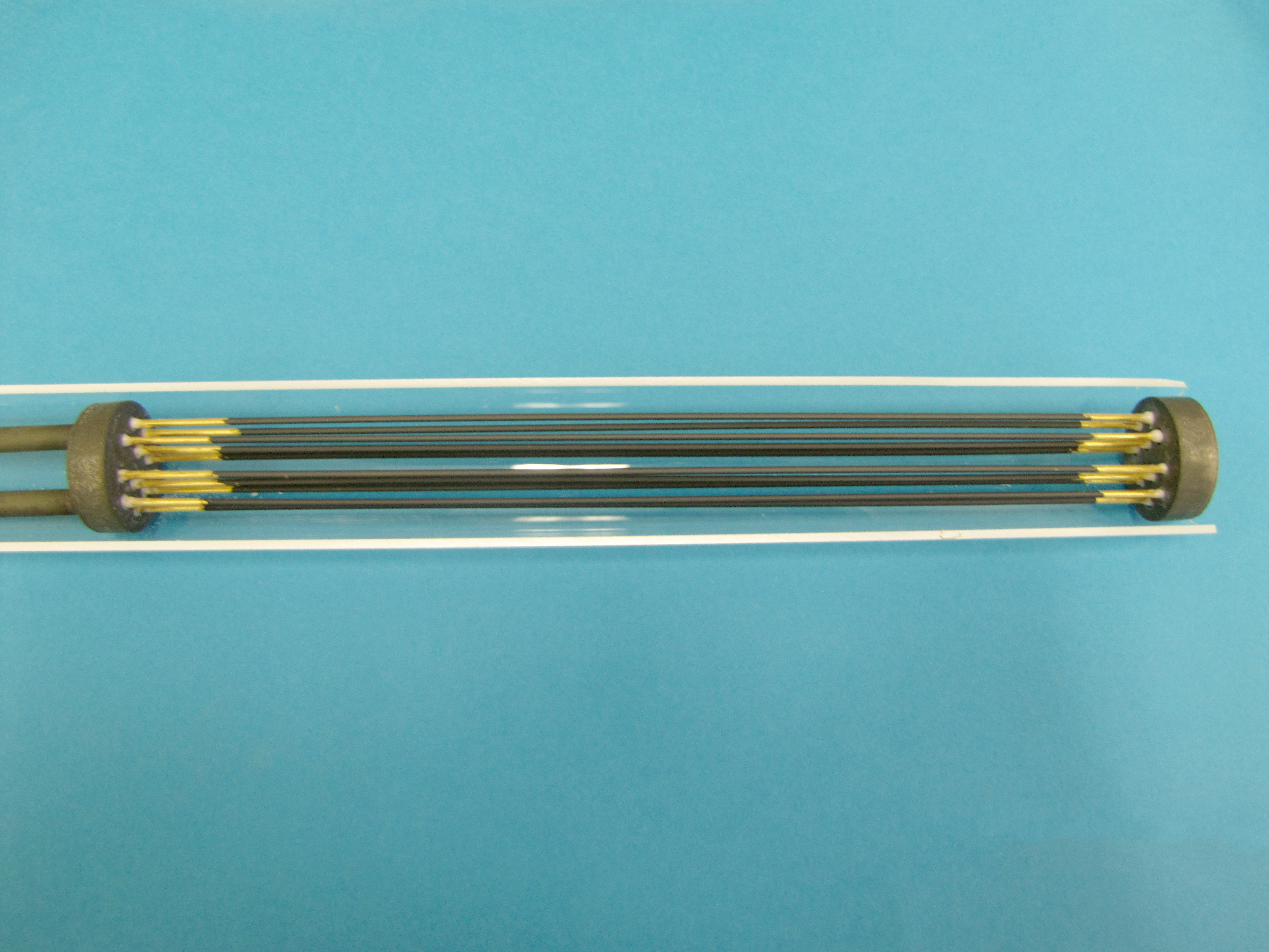

In order to combine the special material properties of perovskites with an effective specific membrane surface, we have developed oxygen conducting perovskite capillary membranes at Fraunhofer IGB. Compared to conventional geometries (disks, tubes, multi-channel elements), these membranes have the highest packing density (separation area per volume) and extremely low material consumption.

A wet-spinning process followed by sintering enables perovskite capillaries with outer diameters of 750 µm to 3 mm and wall thicknesses of 80 to 300 µm to be produced on a pilot scale. For example, gas-tight capillaries made of the perovskite material BaCoxFeyZrzO3-δ show oxygen permeation of up to 10 ml min-1 cm-2 and excellent selectivity (separation factor O2/N2 > 10,000) at temperatures of 950°C [1].

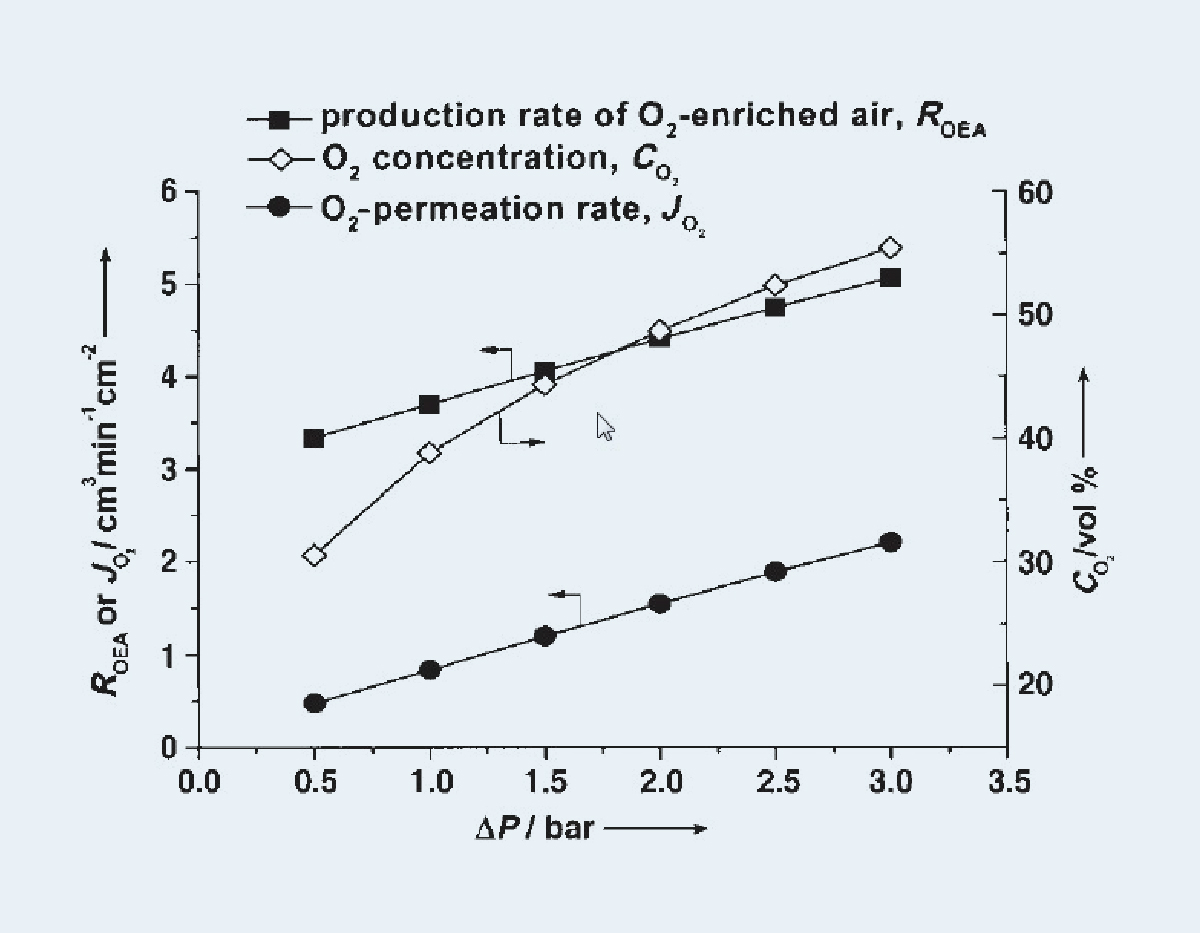

Successful application tests

Together with partners from research and industry, Fraunhofer IGB has tested these membranes for various applications [2, 3]. The capillaries can be used, for example, to produce oxygen-enriched air or even extremely pure oxygen and for the partial oxidation of methane (POM). The splitting of water coupled with the POM using these membranes facilitates the simultaneous production of pure hydrogen and syngas.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB