Especially in the field of technical textiles new process concepts are in high demand. Users are increasingly having a high chemical throughput and simultaneously face growing environmental constraints (e.g. REACH). On this topic, Fraunhofer IGB develops innovative solutions together with industrial companies and textile research institutes.

Here, plasma technology offers a promising approach to equip textiles efficiently and environmentally friendly with desired characteristics - especially water and oil repellent properties.

The conventional, chemical textile finishing often produces harmful by-products or waste products. For example, long fluorocarbon chains are required to equip textiles with oil-repellent (oleophobic) properties. However, molecular fragments of finishing chemicals are released during the finishing process, oder during subsequent washing and re-impregnation. Some of these fragments and their reaction products are toxic and therefore represent a problem.

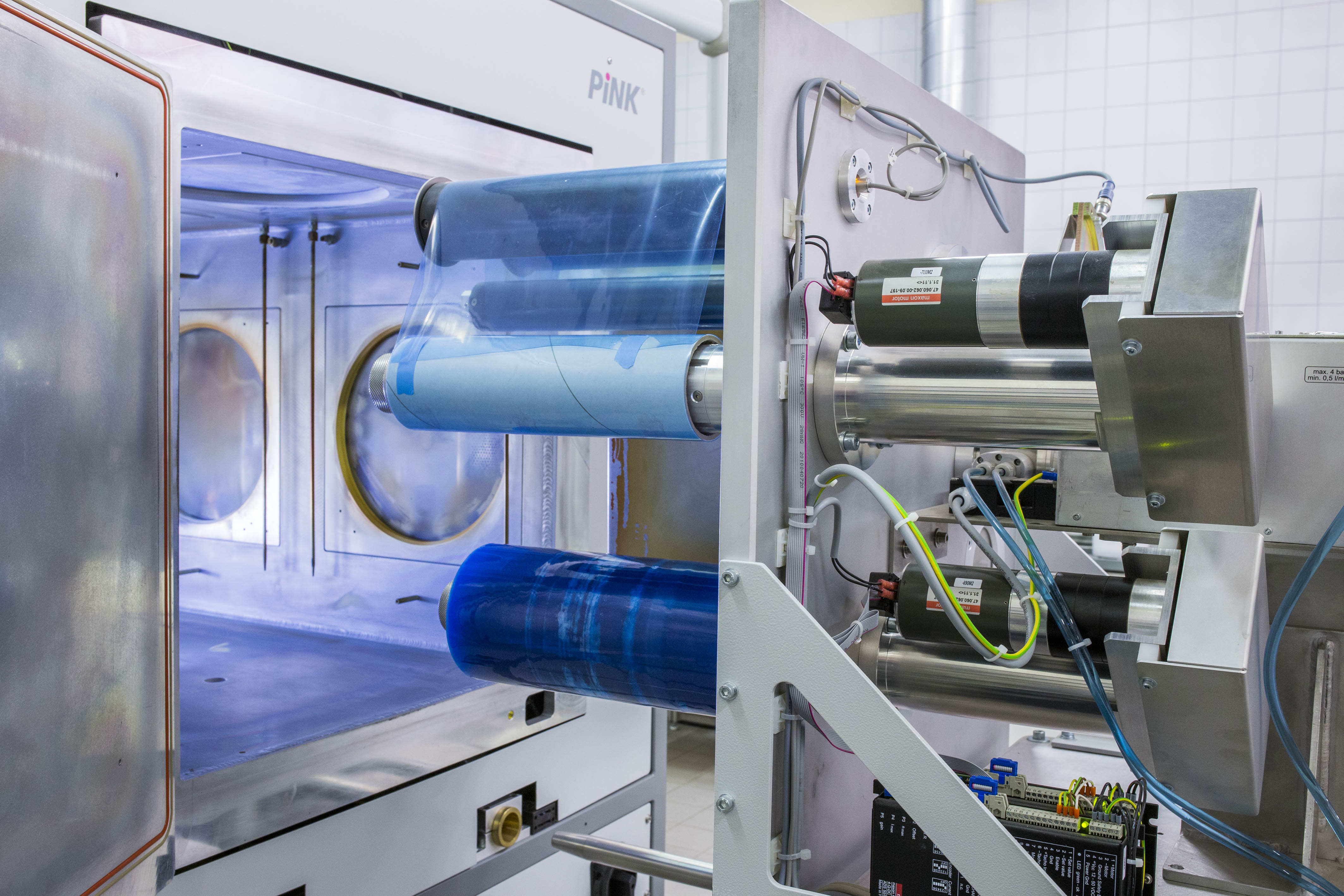

Plasma treatment of textiles is chemically covalent and therefore works with a minimum use of chemicals.

It makes it possible to apply stable coatings on surfaces. Plasma treatment achieves a high film quality while working at high processing speed.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB