Synthesis of derivatives of natural products

Organic synthesis has always been an essential technology for the use of natural products. With the increasing availability of biobased feedstocks these compounds can be used for the synthesis of products for different applications. For the support of our partners, we offer services from literature studies for the development of synthetic procedures in lab scale.

Building blocks for new biobased thermoplastic polymers

One of our main topics in the field of “Organic Chemistry“ is the modification of natural products. Typical substrates are terpenes, which we modify to monomers for the synthesis of new biobased polymers.

An example is the synthesis of lactams from 3-carene. We were able to selectively synthesize two different lactam isomers, one of which can be polymerized to a semicrystalline, the other to a fully amorphous polyamide.

Another example of our work is the combination of bio- and chemocatalysis for the conversion of camphor to diols and diamines which can be polymerized to polyamides and polyesters (doi.org/10.1002/cctc.201300344). An obvious modification of terpenes is the epoxidation of the double bond in the terpene molecules, which was intensively studied chemically as well as by enzymes. So also the epoxidation of terpenes which easily isomerize under acidic conditions is possible.

Building blocks for epoxy resins

Next to the modification of terpenes for the synthesis of polyamides and polyesters we work on the production of a prepolymer as starting material for epoxyresins based on limonene.

Modified biopolymers

Additionally to the synthesis of monomers for polymerization reactions we work on the modification of polysaccharides, which is another important topic in the innovation field. In the ChitoMat project we are working on chitin derivatives which can be processed thermally. So new polymers can be synthesized by combination of classical synthesis and the use of biobased resources. The goal is to develop a new biobased polymer for additive manufacturing.

Scale-up

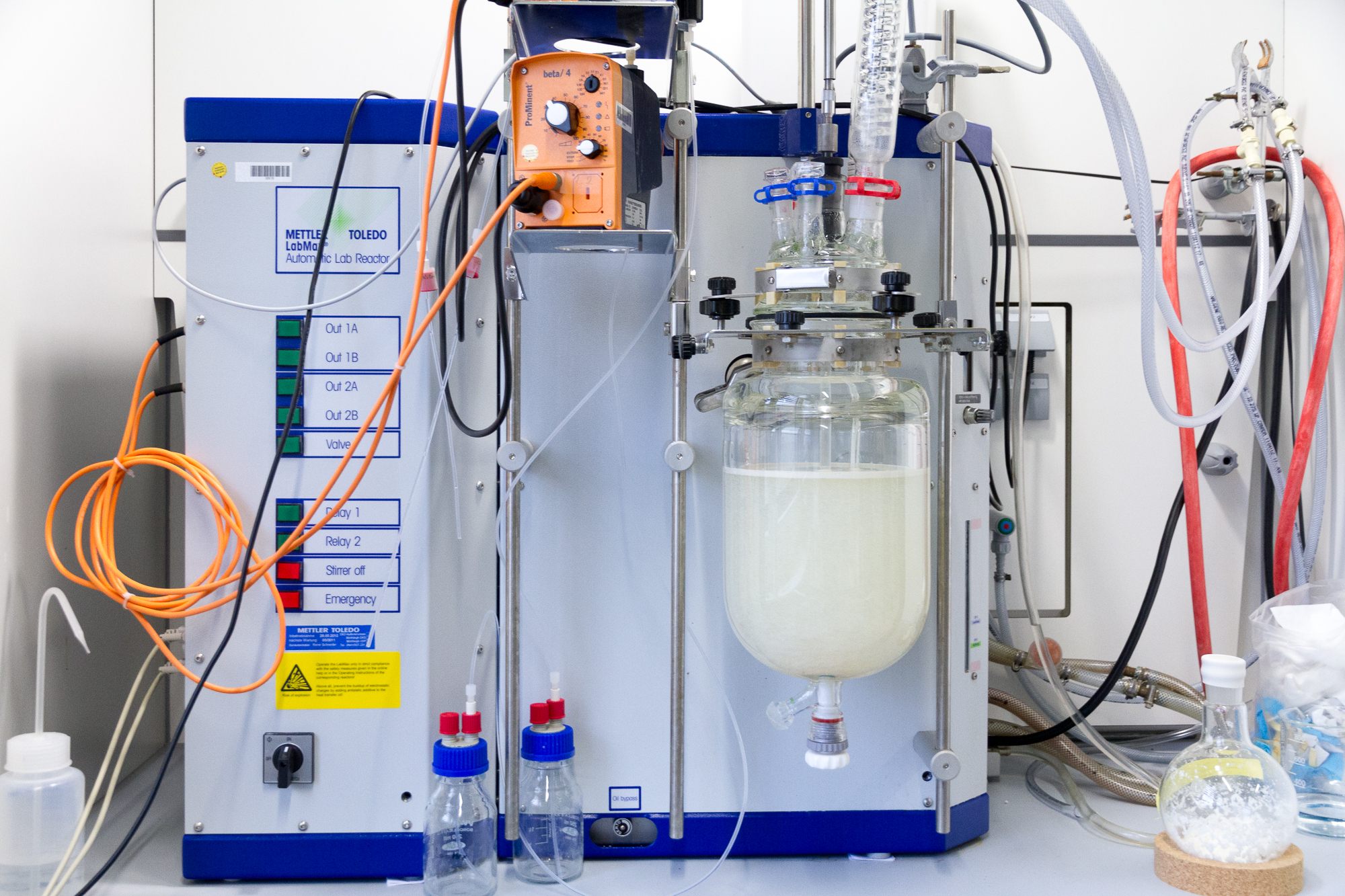

After the development of new synthetic procedures in the lab, the equipment and the know-how for a first scale-up into an automatized 4-liter reactor (LabMax from Mettler-Toledo) and a second scale-up to a volume of 100 liters in the technical-scale modules at Fraunhofer CBP is available.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB