Gas mixtures can be separated using different types of membranes. Compared to cryogenic methods, membranes offer high selectivities and are also more energy-efficient, since no phase transition is necessary.

Gas separation

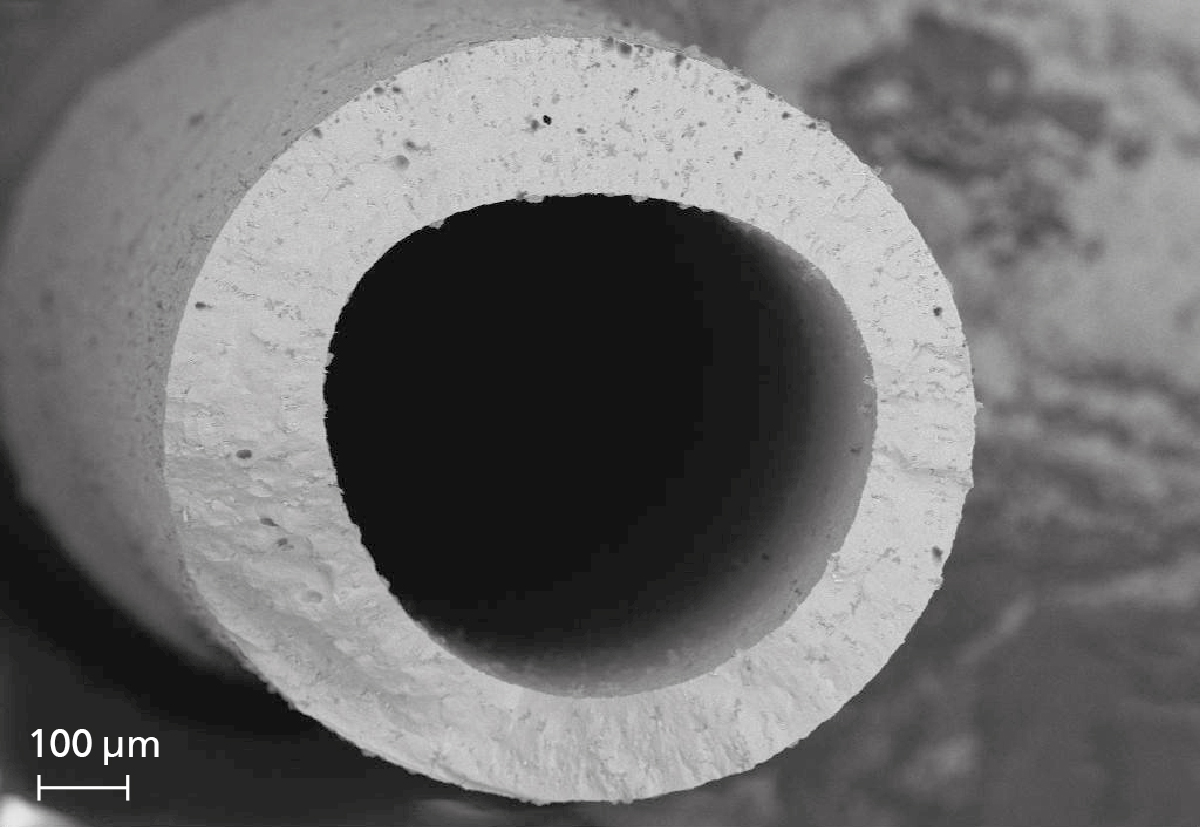

Oxygen separation with perovskite capillary membranes

In recent years, mixed-conducting perovskites have increasingly come into focus as membrane materials for the selective separation of oxygen from gas mixtures. In order to combine the special material properties of mixed-conducting perovskites with an effective specific membrane surface, we have developed oxygen-conducting perovskite capillary membranes at Fraunhofer IGB. Compared to conventional geometries (disks, tubes, multi-channel elements), these membranes have the highest packing density (separation area per volume) and extremely low material consumption.

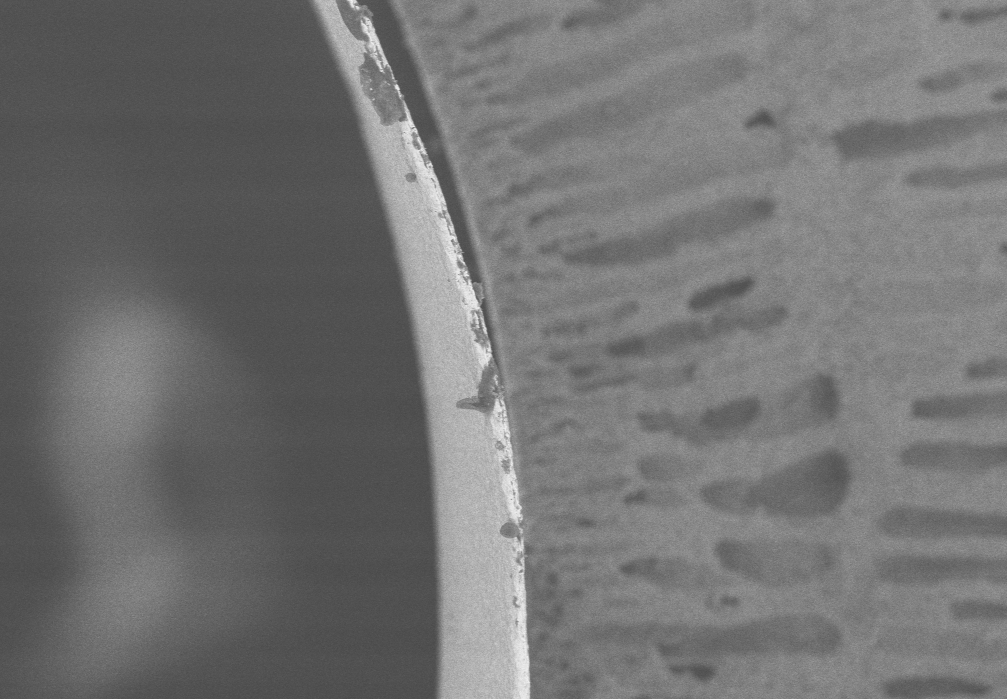

Hydrogen separation with palladium-coated alumina capillary membranes

Palladium and its alloys can incorporate hydrogen in the form of hydrides in the metal lattice. We have developed palladium-coated alumina capillary membranes for the separation of hydrogen. This achieves a high specific separation area. Very thin, gas-tight palladium (alloy) layers can be produced by electroless plating.

CO₂ separation

For the separation of CO2 from other gases we use different separation principles.

Size exclusion using metal organic frameworks (MOF)

For separation by size exclusion, we use so-called metal-organic frameworks (MOF), which we can incorporate into mixed-matrix membranes. These then have porous structures of defined size in the lower nanometer range, which can be used for gas separation.

Absorption using ionic liquids

We also use ionic liquids (IL), which can absorb CO2 with high capacity. If these are soaked into porous membranes via capillary forces, these carrier-supported liquid membranes can be used for CO2 removal.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB