The Black Forest region wants to develop wood waste as a local resource for the decentralized production of biohydrogen as a regenerative energy carrier. To this end, the potential of wood waste for the production of hydrogen and its energetic use is being investigated and two processes for the biotechnological production of hydrogen and co‑products is being developed and demonstrated in an integrated pilot plant at the Black Forest Campus.

H2Wood – BlackForest – Biointelligent Hydrogen Production from Wood and Waste Wood in the Black Forest

Challenges and objective

Due to its high proportion of forest, the economy of the Black Forest is strongly oriented towards the use of wood. This generates significant amounts of wood waste, e.g. residual wood, waste wood and production waste, some of which currently has to be disposed of at high cost. For sustainable and regional value creation, the project "H2Wood – BlackForest" aims to develop these wood wastes as a local resource for the production of biohydrogen and biobased products.

Solution approach

As a basis for the implementation of a wood-based circular economy in the region, aspects and potentials of hydrogen-based sustainability in the Black Forest as well as scenarios for an accelerated reduction of CO2 emissions are investigated. The studies conducted by Fraunhofer IPA and University Institute IFF are directed at the wood processing industry, mobility service providers, technology companies as well as energy suppliers, municipalities and rural/city districts and will be summarized in a hydrogen roadmap for the Black Forest region.

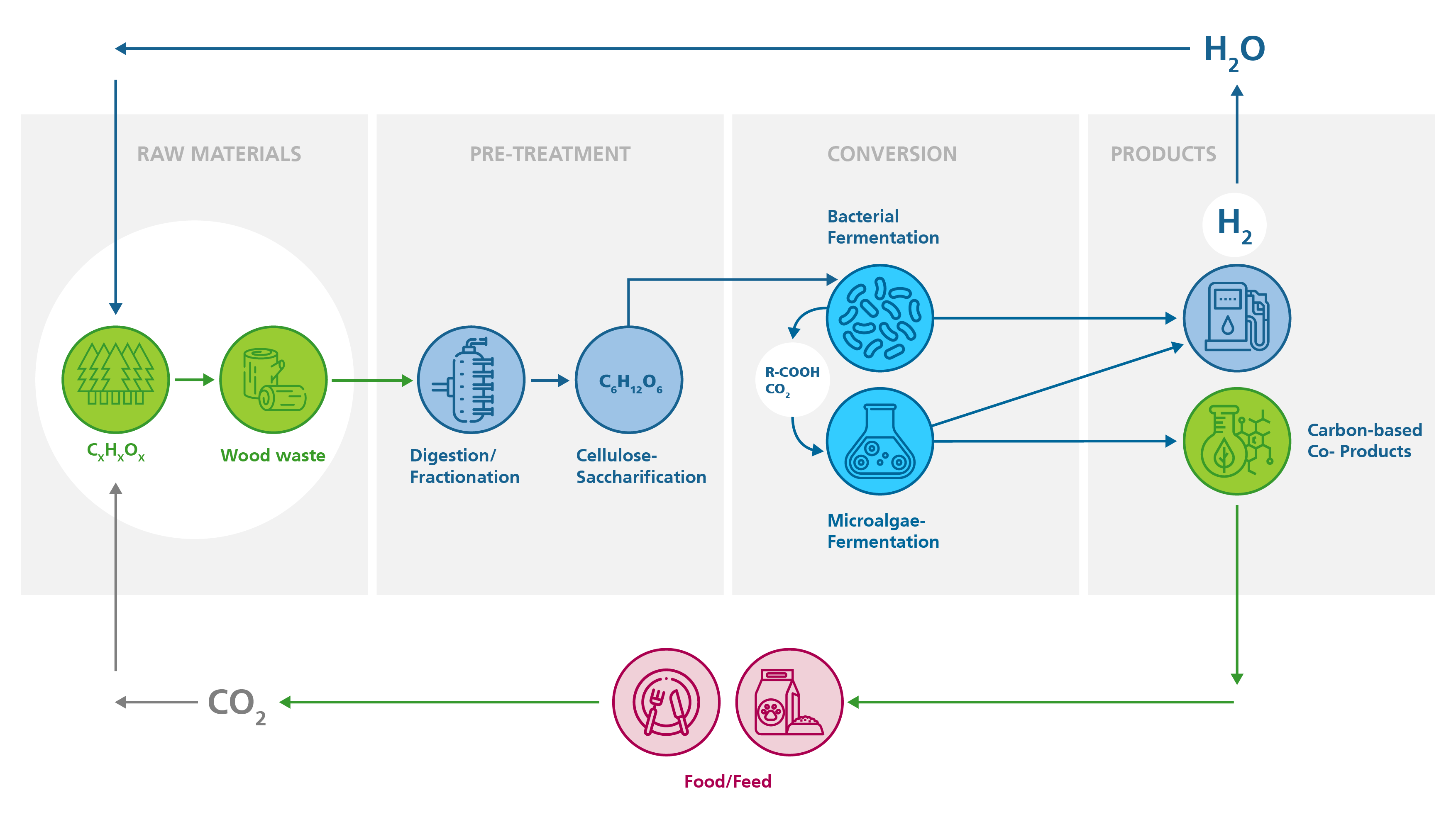

For the process engineering aspects, a plant concept for the production of biohydrogen from wood waste by means of biotechnological processes is analyzed and evaluated as an alternative to thermochemical processes. As a first step, a pretreatment process will be developed to remove chemical components such as adhesives or varnishes from waste wood, followed by fractionation and cleavage of the cellulose obtained into sugars. For the biotechnological conversion of the wood sugars into hydrogen, Fraunhofer IGB investigates and combines two fermentation processes using hydrogen-producing microalgae and bacteria, respectively.

To demonstrate the technical feasibility and obtain initial operating data, the process stages will be set up as semi-mobile modules on the basis of the design data determined on a laboratory scale at Fraunhofer IGB and integrated into an automated plant at the Black Forest Campus.

Impact and application potentials

By reducing CO2 emissions, the project helps to achieve the climate protection targets. On the one hand, the regeneratively produced energy source biohydrogen replaces previous fossil energy sources, for example in the mobility and industry sectors. On the other hand, the biotechnological approach links the energy recovery of the wood waste with a material use, in which the CO2 released from the wood during the biotechnological conversion is bound in the form of carbon-based co-products. Thus, the combined material utilization of waste wood and wood production waste also contributes to the establishment of a circular economy based on renewable raw materials with biobased products for the food and feed industry as well as the chemical industry.

Results

Pre-treatment: fractionation and saccharification of waste and residual wood

The main component of wood is lignocellulose, structural material in the cell wall of all woody plants and the most common renewable raw material. Lignocellulose basically consists of polymeric C6 and C5 sugars (cellulose, hemicellulose) and the biopolymer lignin.

In order to make the wood waste usable, residual wood, pallets, construction waste or old garden fences for example are first shredded, sieved and separated from physical impurities that could damage the biorefinery plant in the further process. This is followed by chemical-thermal digestion. For this purpose, the wood is boiled under pressure at up to 200 °C in an ethanol-water mixture. Lignin as well as adhesives, solvents and varnishes from the wood waste dissolve in ethanol so that the chemical impurities are separated from the wood fibers.

The wood fiber fraction that remains after cooking, which contains cellulose and hemicellulose, is broken down into its individual sugar molecules – glucose and xylose – in the saccharification step. These serve as a substrate and carbon source for the hydrogen-producing microorganisms.

Lignin can be obtained from the liquid fraction as a co-product. It can be used in a variety of ways, including as a bio-based material in composites.

Conversion of sugars from wood to hydrogen

To convert the sugars obtained from the fractionation of wood to hydrogen, Fraunhofer IGB has established and combined two fermentation processes with hydrogen-producing bacteria and microalgae.

Bacterial fermentation: conversion of sugar into hydrogen

To convert the sugars, Fraunhofer IGB is investigating anaerobic fermentation with the bacterium Clostridium. In addition to the target product hydrogen, these bacteria also produce CO2 and organic acids during their growth.

Microalgae: Conversion of CO2 into the co-product lutein

Microalgae are able to use CO2 as a carbon source by means of photosynthesis. In order to utilize CO2 from bacterial fermentation as a carbon source for the microalgae, it is separated from the gas mixture and fed into a photobioreactor in which the microalgae are cultivated. Under the influence of light, the microalgae Chlorella sorokiniana can be used to synthesize storage substances like starch and carotenoids such as lutein as additional co-products that can be used by various industrial sectors.

In a second step, we transfer the microalgae to a specially developed reactor in which they release hydrogen by means of direct photolysis.

Biorefinery pilot plant for a wood-based circular economy

The modules of the pilot plant complex were already set up and tested at Fraunhofer IGB in 2024. Planning for the construction at Campus Schwarzwald is progressing well. The plant is scheduled to go into operation in summer/autumn 2025. This will pave the way for demonstrating the biotechnological production of hydrogen on a larger scale for the first time.

The new biotechnological approach combines the energy recovery of wood waste into hydrogen with a material use. The CO2 released from the wood is bound in the form of carbon-based co-products and thus fed back into the natural carbon cycle.

Project information

Project title

H2Wood – BlackForest – Biointelligent hydrogen production from wood and waste wood in the Black Forest

Project duration

August 2021 – July 2025

Project partners

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, Stuttgart, Germany (Coordination)

- Campus Schwarzwald (Centrum für Digitalisierung, Führung und Nachhaltigkeit Schwarzwald gGmbH), Freudenstadt, Germany

- Fraunhofer Institute for Manufacturing Engineering and Automation IPA, Stuttgart, Germany

- University of Stuttgart, Institute of Industrial Manufacturing and Management IFF, Stuttgart, Germany

Funding

We would like to thank the German Federal Ministry of Education and Research (BMBF) for funding the project "H2Wood – BlackForest", promotional reference 03SF0669A.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB