Hadas Simon-Baram, Steffen Roth, Christina Niedermayer, Patricia Huber, Melanie Speck, Julia Diener, Michael Richter, Shimon Bershtein. A High-Throughput Continuous Spectroscopic Assay to Measure the Activity of Natural Product Methyltransferases, ChemBioChem 2022, e202200162, https://doi.org/10.1002/cbic.202200162

Subrizi, F., Wang, Y., Thair, B., Méndez-Sánchez, D., Roddan, R., Cárdenas-Fernández, M., Siegrist, J., Richter, M., Andexer, J. N., Ward, J. M., Hailes, H. C. Multienzyme One-Pot Cascades Incorporating Methyltransferases for the Strategic Diversification of Tetrahydroisoquinoline Alkaloids. Angew. Chem. Int. Ed., 2021, 60, 18673, https://doi.org/10.1002/anie.202104476.

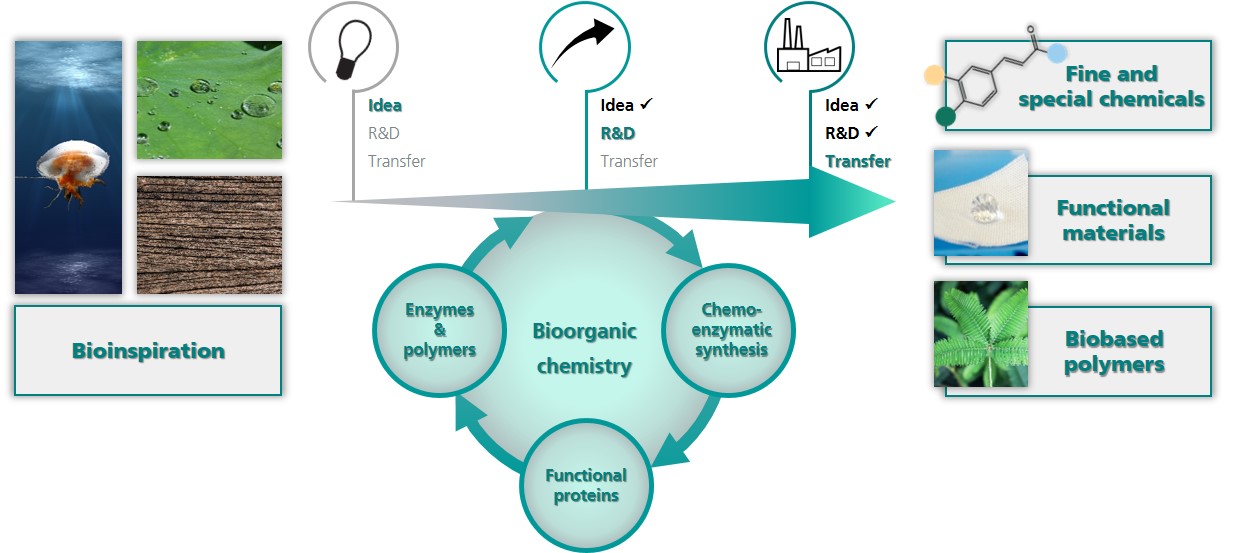

Richter, M., Vieira, L., Sieber, V. Sustainable Chemistry – An Interdisciplinary Matrix Approach. ChemSusChem, 2021, 14, 251, https://doi.org/10.1002/cssc.202001327.

Hofer, M., Diener, J., Begander, B., Kourist, R., Sieber, V. Engineering of a borneol dehydrogenase from P. putida for the enzymatic resolution of camphor. Appl Microbiol Biotechnol. 2021,105, 3159–3167, https://doi.org/10.1007/s00253-021-11239-5.

Roth, S., Funk, I., Hofer, M., Sieber, V. Chemoenzymatic Synthesis of a Novel Borneol‐Based Polyester. ChemSusChem, 2017, 10(18), 3574-3580, https://doi.org/10.1002/cssc.201701146.

Hofer, M., Strittmatter, H., Sieber, V. Biocatalytic Synthesis of a Diketobornane as a Building Block for Bifunctional Camphor Derivatives. ChemCatChem, 2013, 5(11): p. 3351-3357, https://doi.org/10.1002/cctc.201300344.

Reiter, J., Strittmatter, H., Wiemann, L.O., Schieder, D., Sieber, V. Enzymatic cleavage of lignin β-O-4 aryl ether bonds via net internal hydrogen transfer. Green Chemistry, 2013, 15(5): p. 1373-1381, https://doi.org/10.1039/C3GC40295A.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB