We develop and optimize materials and ink formulations with adjustable properties for use in pharmaceutical and cosmetic formulations as well as for additive manufacturing processes. We use biopolymers such as gelatin, collagen, hyaluronic acid, chondroitin sulfate, and heparin, which can be functionalized through targeted chemical modifications—for example, with methacrylic, thiol, or benzophenone groups.

Our materials are characterized by individually adjustable viscosity, gelling behavior, and mechanical properties. They can be used as water-insoluble hydrogels with defined strength or as active ingredient reservoirs with controlled release kinetics. In addition, they offer process-adapted fluid properties and are suitable as cell-compatible, tissue-specific matrices.

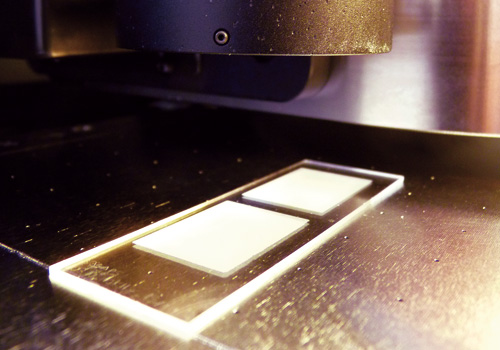

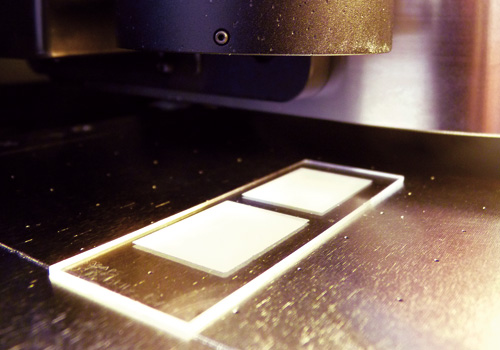

In the field of additive manufacturing, we support applications such as inkjet printing and pneumatic and extrusion-based dispensing. Our services include the development of customized materials, comprehensive consulting, and technology transfer to your processes.

We use modern analytical methods for quality assurance and further development. Common (immuno)histological methods and cell culture assays round out our offering.

Additive processes and printing devices

- Inkjet printing: Jet-printer (Nanoplotter, GeSiM mbH, D; DMP 3000, Fujifilm, USA)

- Pneumatic or extrusion based dispenser (Prototype, Unitechnologies, CH; System 30, Hyrel3D, USA)

Biomaterials with adjustable properties

- Gelatin

- Collagen

- Hyaluronic acid

- Chondroitin sulfate

- Heparin

Chemical modifications

For crosslinking

- methacrylic functions

- thio functions

- benzophenone

For reducing intermolecular interactions (masking)

- e.g. acetyl groups (DE 10 2012 219 691 B4 2015)

Functional features and applications

- Control of viscosity

- Control of gelling behavior

- Crosslinked hydrogels with adjusted stiffness, swelling

- API storage with controlled release

- Biobased fluids with adjusted flow characteristics

- Cytocompatible or tissue-specific 3D matrices

Analysis

- NMR

- Rheology

- Compression testing at physiological conditions

- Cytocompatibility

- Pyrogen detection assay (cell-based)

Cells and tissues

- Primary cells isolated from human or mammalian biopsies, e.g. mesenchymal stem cells / chondrocytes, endothelial cells, mature adipocytes, skin cells

- 2D and 3D culture

- Standard (immune)histological techniques and cell culture assays

- Flow cytometry for characterization of cells and cytokines

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB