Xylonic acid as a replacement for gluconic acid

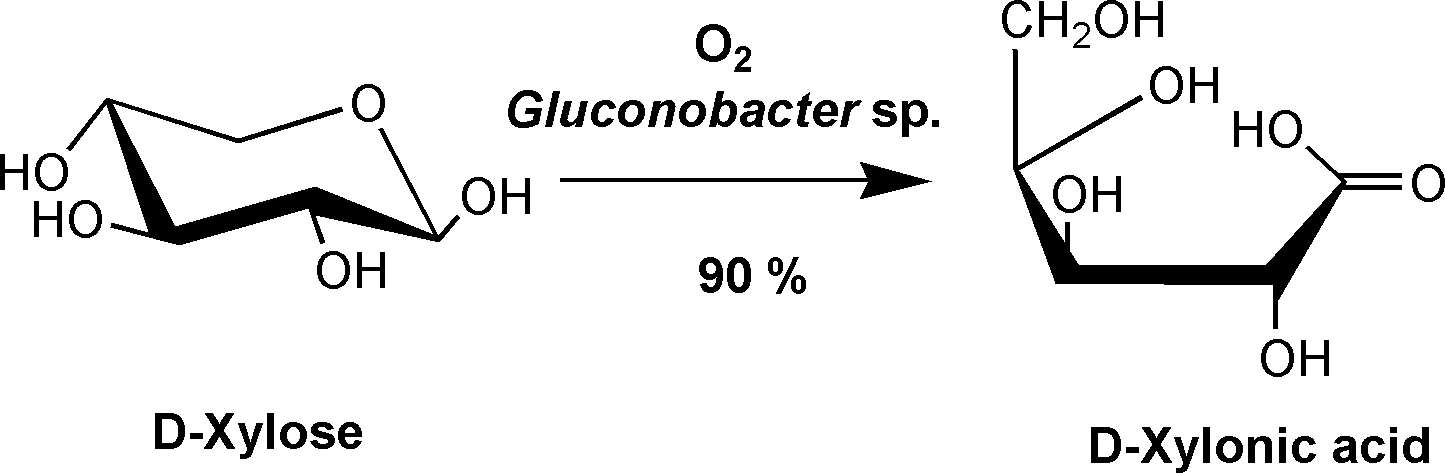

Gluconic acid is an important constituent of foodstuffs, construction materials and dyes [1]. The acid is produced from glucose, which is obtained from plants rich in starch and thus competes with the production of foodstuffs. An alternative to gluconic acid is xylonic acid: on the one hand, this has similar properties and, on the other hand, it can be obtained from plant components containing lignocellulose or from agricultural waste material. The aim was therefore to develop an efficient process for obtaining xylonic acid from xylose.

250 g/L xylonic acid through optimization

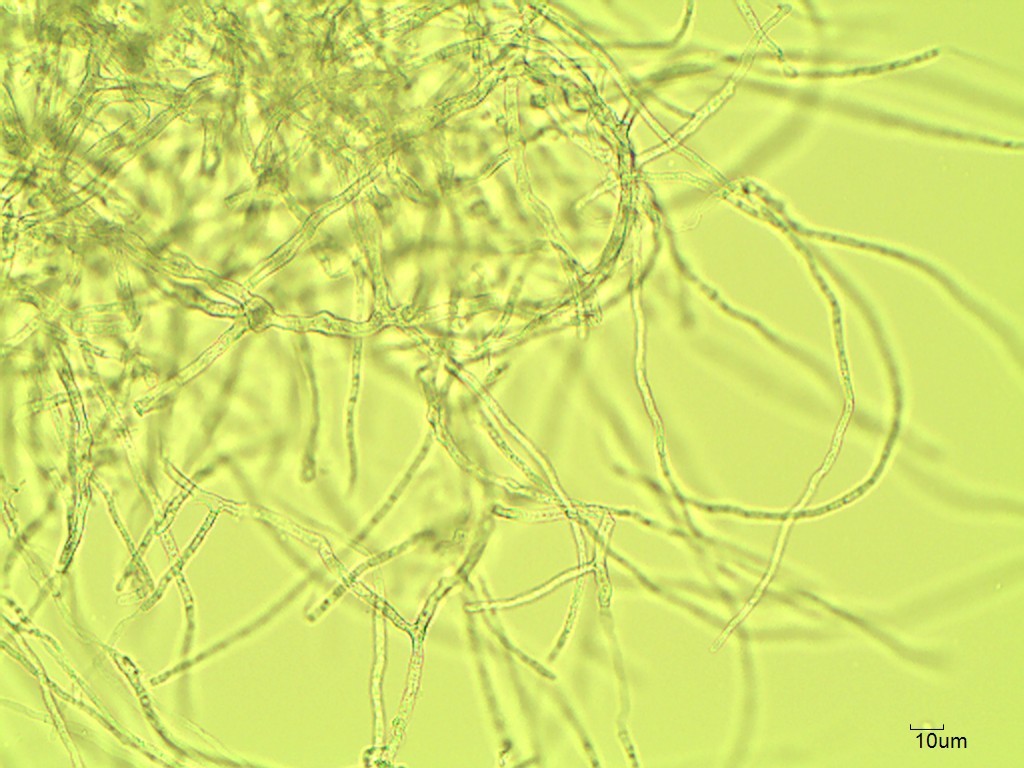

The fermentation-based conversion of xylose is conducted using whole cell catalysis (Gluconobacter sp.), with addition of oxygen as a second reactant. In contrast to competing solutions, fermentation with Gluconobacter sp. has the advantage of being a specific, sustainable and efficient conversion. To date, the team of Industrial Biotechnology Group has achieved a xylonic acid concentration of over 250 g/L through optimization – with a yield of over 90 percent. In the subsequent rudimentary purification process, xylonic acid was obtained at a purity of over 80 percent, which is adequate for technical applications.

Scale-up and sample quantities for application-related investigations

The scalability of the process has already been demonstrated at the Fraunhofer Center for Chemical-Biotechnological Processes CBP by the team in the Biotechnological Processes Group with the 100-liter fermentation, a scale-up to 300 liters is planned. We are already making smaller quantities available for investigations for specific applications. For example, xylonic acid can be tested as a substitute for gluconic acid as a curing retardant for concrete or chelating agent.

Literature

[1] Toivari, M.H., Y. Nygard, M. Penttila, L. Ruohonen, and M.G. Wiebe, Microbial D-xylonate production. Applied Microbiology and Biotechnology, 2012. 96(1): p. 1-8.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB