Humidifier membranes for water management in fuel cells

One approach to a sustainable energy economy is the use of hydrogen as an energy carrier. This can be produced by electrolysis, e.g. by fluctuating renewable energy, and used for mobile and stationary applications by generating electricity from it with fuel cells. The management of the resulting water plays an important role for the performance and lifetime of the fuel cell.

Commercial membrane humidifiers for moisture management in automotive fuel cells insufficient

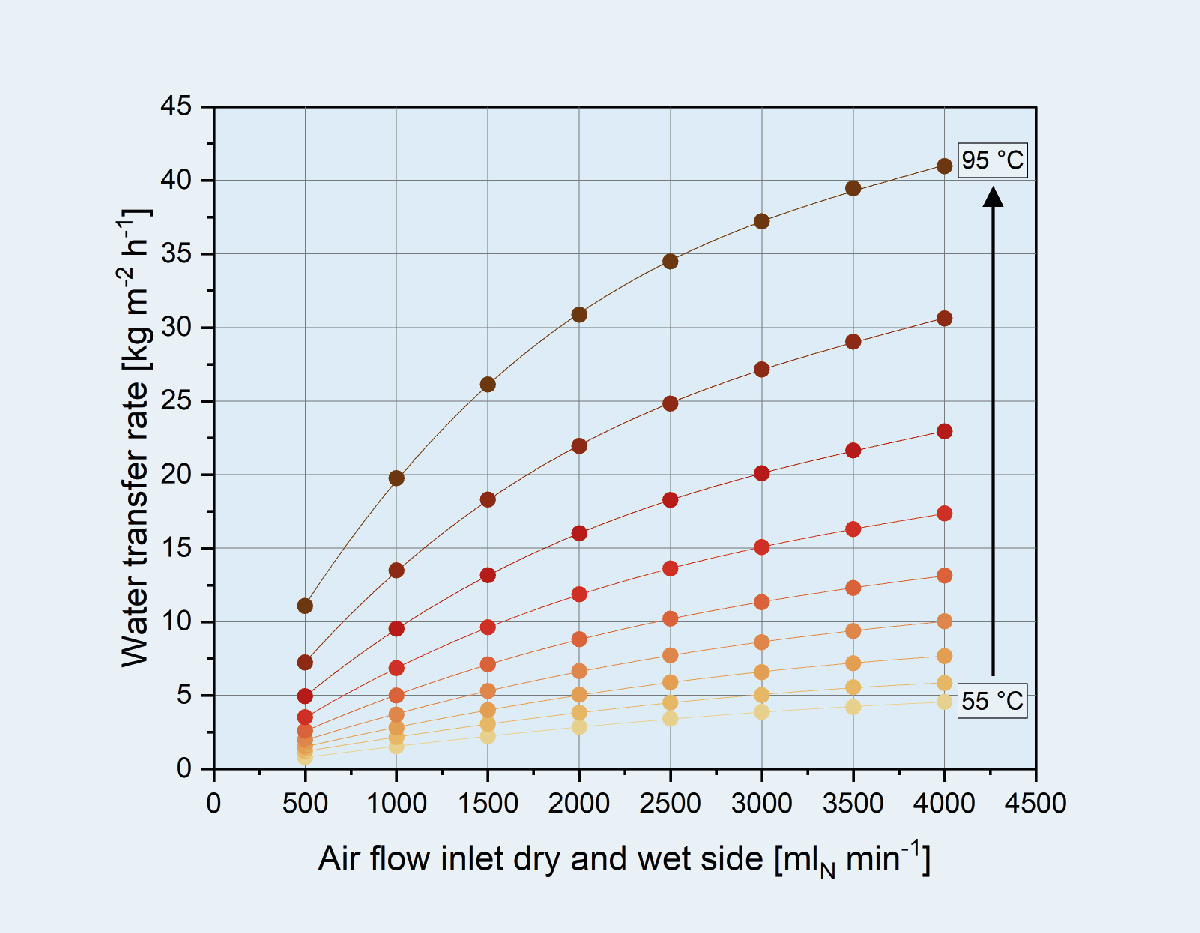

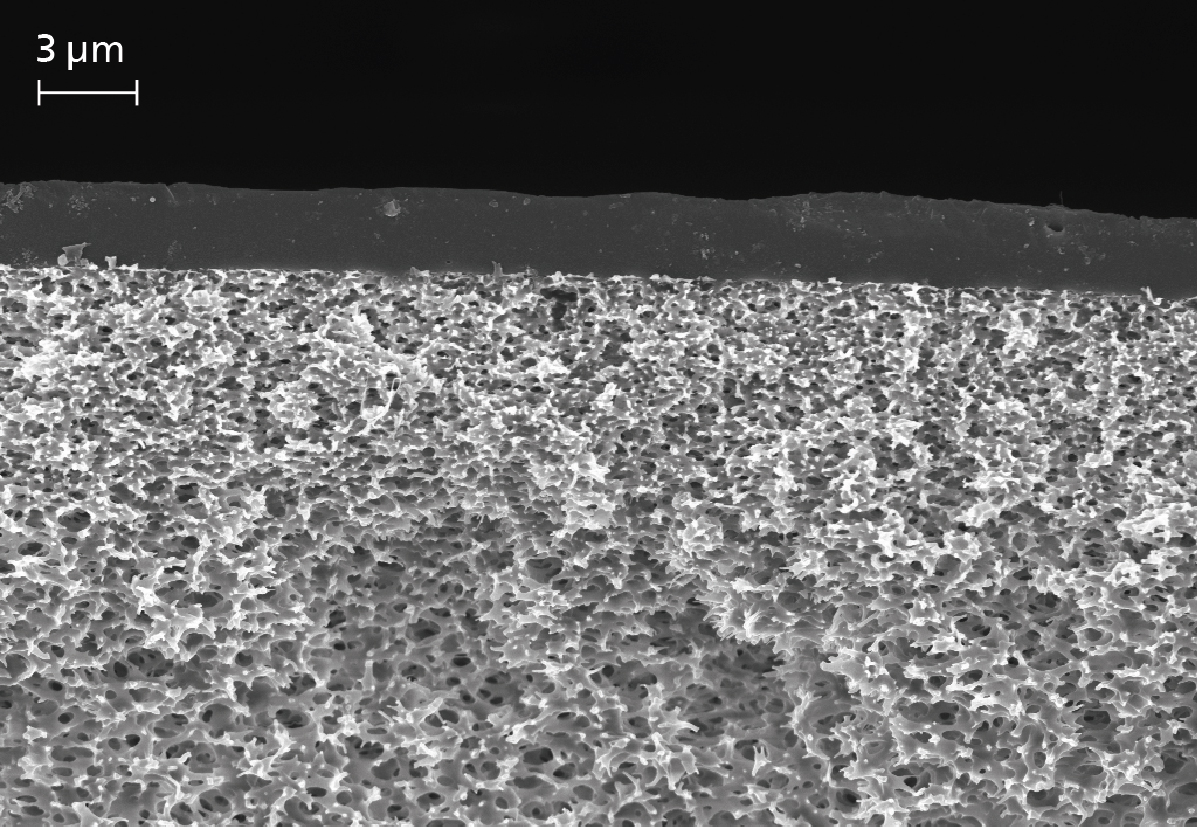

Membrane humidifiers can be used as an external component to protect the ionomer membrane in the fuel cell from drying out at any time.

However, commercial membrane humidifiers do not adequately meet the very demanding requirements for automotive applications in terms of water transfer, long-term stability, harmful gas tolerance and cost.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB