Functional Particles and Particle Technologies

Functional particle surfaces

The surfaces of nano- and microparticles can be additionally modified with functional properties and active groups to optimize the desired material properties:

- Specific adsorber particles

- Biofunctionalization

- Click chemistry

- Active ester

Adjustment and optimization of the matrix properties

In addition, blends of several materials that combine the advantages of both materials are being developed in such a manner that the specific properties can be adjusted in a targeted manner. Chemical modification of the materials at Fraunhofer IGB also enables completely new properties of the materials in bulk and in particulate form. We develop this modification individually in cooperation with our customers.

Moreover, it is possible to specifically slow down or reduce the release of active substances. For this purpose, in addition to chemical modification, we also use biocompatible crosslinking reactions, which are based on electrostatic interactions and thus contribute to the prevention of harmful substances in the environment and the body.

Materials used

Chitosan

The biopolymer chitosan is derived from the renewable raw material chitin, the world's second most abundant biopolymer. It is mainly obtained from the shells of crustaceans. The chitin is deacetylated in a basic aqueous environment.

Our offer

Fraunhofer IGB uses high-quality and especially pure chitosans with consistent product quality, on request also in GMP quality. Furthermore, a team of our institute produces individually modified chitosan according to your requirements. In addition, we develop and produce particles in nanometer or micrometer scale using various particle technologies for you.

Alginate

The renewable biopolymer alginate - also known as alginic acid - is mainly obtained from brown algae. It is water-soluble and forms a hydrogel with water.

It is particularly suitable for innovative active ingredient formulations, as it has already been approved by the U.S. Food and Drug Administration (FDA) for drugs and medical devices. Especially advantageous for various applications in the environmental, pharmaceutical and food sectors is the high water absorption capacity and mucoadhesion of this material.

Our offer

Fraunhofer IGB uses high-quality and particularly pure alginates with consistent product quality, on request also in GMP quality. In addition, we produce particles in nanometer or micrometer scale using various particle technologies for you.

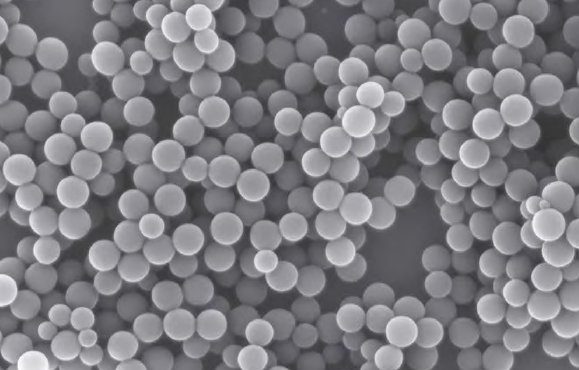

Particle technology: Synthesis of functional particles

Nano- and microparticles with diameters ranging from 50 nanometers to several 100 micrometers are produced at Fraunhofer IGB from organic and inorganic materials. Research focuses on the design of tailor-made particles as carrier materials for biotechnology and medicine and for the separation (enrichment) of low-concentration valuable substances or interfering/polluting substances.

A number of different particle technologies are available at Fraunhofer IGB:

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB