The use of renewable raw materials and biogenic residues in sustainable production processes offers alternative solutions for chemistry based on fossil raw materials. Particular importance is attached to white/industrial biotechnology, which produces platform and fine chemicals as well as fuels using biotechnological or combined processes. Biogenic raw materials such as lignocellulose or vegetable oils are preferred in such biorefinery concepts in order to obtain environmentally compatible products.

Research in the field of industrial, white biotechnology at Fraunhofer IGB is performed in an interdisciplinary manner. The activities of the Industrial Biotechnology Group headed by Dr. Susanne Zibek focus on establishing, optimizing and upscaling biotransformation processes in which raw materials are transformed into usable products either with the aid of microorganisms or enzymes. We combine the development of transformation processes on a laboratory scale and the optimization of the biocatalysts themselves with the transfer of the processes to larger scales. In addition, we can increase the scale up to the pilot scale either at our customers' and project partners' facilities or at the Fraunhofer Center for Chemical-Biotechnological Processes CBP.

With our interdisciplinary orientation in biology, chemistry and process engineering, we cover the entire process chain and create the prerequisites for the scalability of our processes already at the laboratory scale. Cooperation with a wide variety of project partners from industry enables us to develop ecologically and economically sensible, sustainable future technologies.

Bioprocess Engineering

Tabbed contents

Our research

Services

Strain development

- Creation of vectors (fusion proteins for purification, secretion, immune assays)

- Metabolic engineering: knock out or overexpression of genes

- Overexpression of enzymes in pro- and eucaryotic systems

Bioprocess technology

- Development of scalable fractionation and/or conversion processes of waste streams to valuable raw materials (chitin, insect fats, etc.) with combinations of mechanical, enzymatic and high pressure processes.

- Development of production processes for bio based chemicals and materials (e.g. biosurfactants)

- Development and optimization of enzyme conversion procedures in stirred tank or fixed bed reactors

- Development and optimization of scalable fermentation processes

- Contract fermentation for the production of biomass, enzymes, or metabolites up to 30-L scale under S1 and S2 conditions and up to 10 m3 scale (S1) at Fraunhofer CBP

- Development of purification methods (e.g. biomass separation, filtration, normal phase chromatography, precipitation, solvent extraction)

- Process intensification for the increase in the space-time yield

Equipment

Molecular biology

- Thermal cycler to amplify segments of DNA via the polymerase chain reaction

- Agarose gel electrophoresis and polyacrylamide gel electrophoresis (PAGE)

Incubators and anaerobic workbench

- Several temperature-controlled incubators and incubation shakers

- Anaerobic workbench

Chemical and enzymatic reaction systems

- Temperature-controlled shakers for 24 parallel approaches (2 to 20 ml scale)

- Temperature-controlled stirring system for 6 parallel approaches (30 to 200ml scale)

- Glass reactors with several different stirrer geometries and baffles (1 l and 10 l scale)

Fermenters and bioreactors

- Micro-bioreactor for up to 48 parallel fermentations on a (1.5 ml scale)

- Multi-fermenter-system for up to 8-times the parallel approaches (1.2 l scale, biological security level S2)

- Multi-fermenter-systems for 3 x 4-times the parallel approaches (1.5 l scale, biological security level 1)

- Small-scale fermenter (each 2 x 3.6 l and 7 l scale, biological security level S2)

- Fermenter of the technical center (42 l scale, biological security level S2)

- Accompanying process control systems including exhaust gas analysis for the regulation of Fed-Batch processes with different supplementary feeding processes

Digestion equipment

- High-pressure reactor – (1 l scale), e.g., for pulping bio mass

- Inline-disperser (up to 350 l/h) with several applications for the homogenization and production of emulsions and dispersions

- Ultrasonic laboratory homogenizer for cell disruption, homogenization and degassing with different attachments (sonotrode, volume up to 15ml)

Anaerobic workbench

Laboratory pilot fermenter LP351 (42 L)

Bioreactor system

Downstream Processing

- Disc separator to separate fermentation broths

- Crossflow filtration systems for micro- and ultrafiltration with ceramic or polymeric hollow fiber modules (50-2000 cm² membrane surface)

- Automated flash-chromatography for the purification of metabolites

- Continuous rotating evaporator with automated sample supplying and residue drainage

Analysis

- Automatic DC applicaton equipment

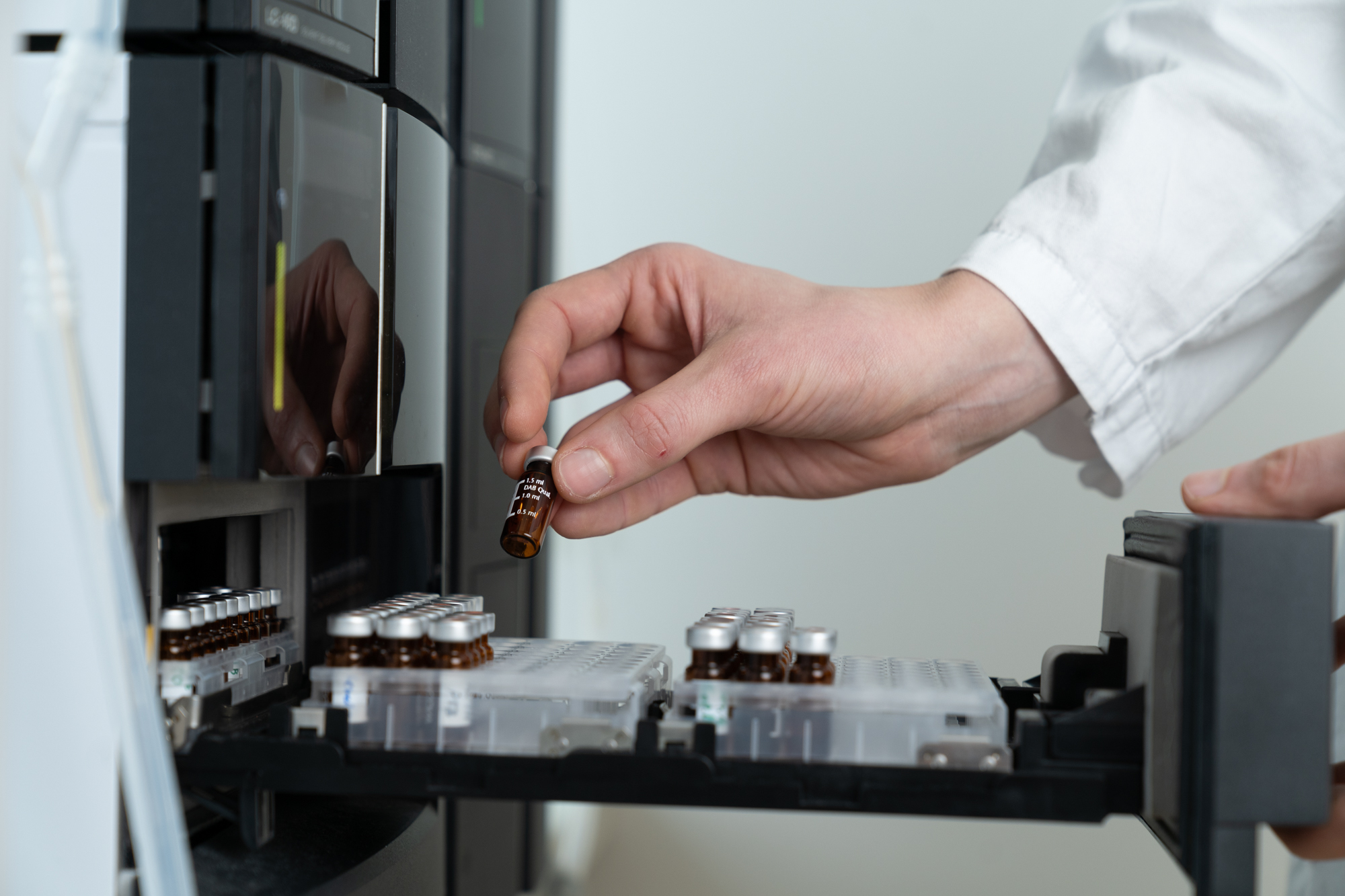

- HPLC- and GPC systems with RI-, UV-, und ELSD-detectors

- Photometric analyzers and multiwell reader

- Multi-enzyme and ion-selective detector (YSI 2950D)

- Microscope (Zeiss, phase and fluorescence contrast, incl. AxioCam camera)

HPLC

HPLC

HPLC

Publications

Publications

| Jahr Year | Titel/Autor:in Title/Author | Publikationstyp Publication Type |

|---|---|---|

| 2026 | Secondary products and bioactive compounds of Hermetia illucens: Extraction, chemical properties, and potential application of chitin and chitosan Triunfo, Micaela; Guarnieri, Anna; Ianniciello, Dolores; Hahn, Thomas; Zibek, Susanne; Scieuzo, Carmen; Falabella, Patrizia |

Aufsatz in Buch Book Article |

| 2025 | Characterizing the growth of PHA-producing microorganisms on short-chain carboxylic acids Leonhardt, Steven; Tamang, Pravesh; Tovar, Günter; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2025 | Erratum: Production of chitosan from Aspergillus niger and quantitative evaluation of the process using adapted analytical tools (Biotechnology and Bioprocess Engineering, (2024), 29, 5, (942-954), 10.1007/s12257-024-00124-3) Krake, Simon; Conzelmann, C.; Heuer, Saskia; Dyballa, Michael Martin; Zibek, Susanne; Hahn, Thomas |

Erratum |

| 2025 | Recovering Ammonia as Ammonium Citrate and Ammonium Sulfate from Sludge Digestion Liquors Using Membrane Contactors in a Pilot Plant Reyes Alva, Ricardo; Mohr, Marius; Tovar, Günter; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2025 | Establishment and characterization of biofloc culture for marbled crayfish Coutinho Carneiro, Vitor; Schäfer, Ines; Díaz-Larrosa, J. Jaime; Böhl, Elias; Hahn, Thomas; Hempelmann, Jule; Venkatesh, Geetha; Nagarajan, Sanjanaa; Roy, Suki; Ng, Yi Long; Böhl, Florian; Zibek, Susanne; Lyko, Frank |

Zeitschriftenaufsatz Journal Article |

| 2024 | Ökobilanz für die Bioprozessoptimierung - Herstellung des Biotensids MEL Bippus, Lars; Briem, Ann-Kathrin; Beck, Alexander; Zibek, Susanne; Albrecht, Stefan |

Zeitschriftenaufsatz Journal Article |

| 2024 | Process Cascade for the Production of Green Polymers from CO2 and Electric Energy Fabarius, Jonathan Thomas; Pietzka, Carsten; Pangotra, Dhananjai; Wriedt, Benjamin; Vieira Dessoy Maciel, Luciana; Sagstetter, Carina; Speck, Melanie; Ziogas, Athanassios; Baumgarten, Nils; Kost, Hans-Joachim; Löb, Patrick; Patzsch, Katja; Bernau, Catherine Rose; Böringer, Sarah; Pico, Davide; Lieske, Antje; Vater, Marcus; Wendler, Ulrich; Roth, Arne |

Zeitschriftenaufsatz Journal Article |

| 2024 | Life cycle assessment for early-stage process optimization of microbial biosurfactant production using kinetic models - a case study on mannosylerythritol lipids (MEL) Bippus, Lars; Briem, Ann-Kathrin; Beck, Alexander; Zibek, Susanne; Albrecht, Stefan |

Zeitschriftenaufsatz Journal Article |

| 2024 | Current trends in medium-chain-length polyhydroxyalkanoates: Microbial production, purification, and characterization Hahn, Thomas; Ortega Alzate, Melissa; Leonhardt, Steven; Tamang, Pravesh; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2024 | Life cycle assessment as a driver for process optimisation of cellobiose lipids fermentation and purification Oraby, Amira; Briem, Ann-Kathrin; Bippus, Lars Ulrich; Rupp, Steffen; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2024 | Past, present and future of glycolipids from Ustilaginaceae - A review on cellobiose lipids and mannosylerythritol lipids Münßinger, Sini; Beck, Alexander; Oraby, Amira; Zibek, Susanne |

Review |

| 2024 | Comprehensive characterization and evaluation of the process chain and products from Euphausia superba exocuticles to chitosan Hahn, Thomas; Egger, Jeannine; Krake, Simon; Dyballa, Michael; Stegbauer, Linus; Seggern, Nils von; Bruheim, Inge; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2024 | Production of chitosan from Aspergillus niger and quantitative evaluation of the process using adapted analytical tools Krake, Simon; Conzelmann, C.; Heuer, Saskia; Dyballa, M.; Zibek, Susanne; Hahn, Thomas |

Zeitschriftenaufsatz Journal Article |

| 2024 | Foam control in biotechnological processes - challenges and opportunities Tiso, Till; Demling, Philipp; Karmainski, Tobias; Oraby, Amira; Eiken, Jens; Liu, Luo; Bongartz, Patrick; Wessling, Matthias; Desmond, Peter; Schmitz, Simone; Weiser, Sophie; Emde, Frank; Czech, Hannah; Merz, Juliane; Zibek, Susanne; Blank, L.M.; Regestein, Lars |

Review |

| 2024 | Transmembrane Chemical Absorption Process for Recovering Ammonia as an Organic Fertilizer Using Citric Acid as the Trapping Solution Reyes Alva, Ricardo; Mohr, Marius; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2023 | Correction: Fermentation and recovery of cellobiose lipids using foam fractionation Oraby, Amira; Hug, Daniel; Weickardt, Isabell; Maerz, Lea; Nebel, Sabrina; Kurmann, Jasper; Rupp, Steffen; Tovar, Günter; Zibek, Susanne |

Erratum |

| 2023 | Usage of chitosan from Hermetia illucens as a preservative for fresh Prunus species fruits: a preliminary analysis Triunfo, Micaela; Tafi, Elena; Guarnieri, Anna; Ianniciello, Dolores; Scieuzo, Carmen; Salvia, Rosanna; Hahn, Thomas; Zibek, Susanne; Falabella, Patrizia |

Zeitschriftenaufsatz Journal Article |

| 2023 | Preliminary investigation on the effect of insect-based chitosan on preservation of coated fresh cherry tomatoes Tafi, Elena; Triunfo, Micaela; Guarnieri, Anna; Ianniciello, Dolores; Salvia, Rosanna; Scieuzo, Carmen; Ranieri, Annamaria; Castagna, Antonella; Lepuri, Samuel; Hahn, Thomas; Zibek, Susanne; Bonis, Angela de; Falabella, Patrizia |

Zeitschriftenaufsatz Journal Article |

| 2023 | Fermentation and recovery of cellobiose lipids using foam fractionation Oraby, Amira; Hug, Daniel; Weickardt, Isabell; Maerz, Lea; Nebel, Sabrina; Kurmann, Jasper; Rupp, Steffen; Tovar, Günter E.M.; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2022 | Techno-Economic Analysis as a Driver for Optimisation of Cellobiose Lipid Fermentation and Purification Oraby, Amira; Rupp, Steffen; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2022 | Optimization and Kinetic Modeling of a Fed-Batch Fermentation for Mannosylerythritol Lipids (MEL) Production with Moesziomyces aphidis Beck, Alexander; Vogt, Franziska; Hägele, Lorena; Rupp, Steffen; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2022 | Environmental Impacts of Biosurfactants from a Life Cycle Perspective Briem, Ann-Kathrin; Bippus, Lars; Oraby, Amira; Noll, Philipp; Zibek, Susanne; Albrecht, Stefan |

Aufsatz in Buch Book Article |

| 2022 | Purification of Chitin from Pupal Exuviae of the Black Soldier Fly Hahn, T.; Tafi, E.; Seggern, N. von; Falabella, P.; Salvia, R.; Thomä, J.; Febel, E.; Fijalkowska, M.; Schmitt, E.; Stegbauer, L.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2022 | Characterization of chitin and chitosan derived from Hermetia illucens, a further step in a circular economy process Triunfo, M.; Tafi, E.; Guarnieri, A.; Salvia, R.; Scieuzo, C.; Hahn, Thomas; Zibek, Susanne; Gagliardini, A.; Panariello, L.; Coltelli, M.B.; Bonis , A. De; Falabella, P. |

Zeitschriftenaufsatz Journal Article |

| 2022 | Antimicrobial properties of chitosan from different developmental stages of the bioconverter insect Hermetia illucens Guarnieri, A.; Triunfo, M.; Scieuzo, C.; Ianniciello, D.; Tafi, E.; Hahn, Thomas; Zibek, Susanne; Salvia, R.; Bonis, A. De; Falabella, P. |

Zeitschriftenaufsatz Journal Article |

| 2022 | Overview on Glycosylated Lipids Produced by Bacteria and Fungi: Rhamno-, Sophoro-, Mannosylerythritol and Cellobiose Lipids Zibek, Susanne; Soberón-Chávez, Gloria |

Aufsatz in Buch Book Article |

| 2022 | Foam fractionation methods in aerobic fermentation processes Oraby, Amira; Weickardt, Isabell; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2021 | Platform and fine chemicals from woody biomass: Demonstration and assessment of a novel biorefinery Nitzsche, R.; Gröngröft, A.; Köchermann, J.; Meisel, K.; Etzold, H.; Verges, Marlen; Bachmann, J.; Leschinsky, Moritz; Saake, B.; Torkler, Sandra; Rößiger, B.; Patzsch, Katja; Pufky-Heinrich, D.; Unkelbach, Gerd |

Zeitschriftenaufsatz Journal Article |

| 2021 | Novel mannosylerythritol lipid biosurfactant structures from castor oil revealed by advanced structure analysis Beck, A.; Haitz, Fabian; Thier, I.; Siems, K.; Jakupovic, S.; Rupp, S.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2021 | Genomic and Proteomic Study of Andreprevotia ripae Isolated from an Anthill Reveals an Extensive Repertoire of Chitinolytic Enzymes Lorentzen, S.B.; Arntzen, M.; Hahn, T.; Tuveng, T.R.; Sorlie, M.; Zibek, S.; Vaaje-Kolstad, G.; Eijsink, V.G.H. |

Zeitschriftenaufsatz Journal Article |

| 2021 | Insect Chitin-Based Nanomaterials for Innovative Cosmetics and Cosmeceuticals Triunfo, M.; Tafi, E.; Guarnieri, A.; Scieuzo, C.; Hahn, T.; Zibek, S.; Salvia, R.; Falabella, P. |

Review |

| 2020 | Draft Genome Sequence of Andreprevotia sp. Strain IGB-42, a Chitinolytic Bacterium Isolated from a Soil Sample of an Anthill in Stuttgart, Germany Vainshtein, Y.; Werner, Nicole; Kirstahler, Philipp; Glanz, K.; Grumaz, Christian; Hahn, T.; Zibek, S.; Sohn, K. |

Zeitschriftenaufsatz Journal Article |

| 2020 | Chitosan application in textile processing and fabric coating Hahn, Thomas; Bossog, Leonie; Hager, Tom; Wunderlich, Werner; Breier, Rudi; Stegmaier, TThomas; Zibek, Susanne |

Aufsatz in Buch Book Article |

| 2020 | Antibacterial properties of glycosylated surfaces: Variation of the glucosidal moiety and fatty acid conformation of grafted microbial glycolipids Valotteau, C.; Roelants, S.L.K.V.; Dasaiyan, P.; Zibek, S.; Günther, Michael; Soetaert, W.; Everaert, B.; Pradier, C.-M.; Babonneau, F.; Baccile, N.; Humblot, V. |

Zeitschriftenaufsatz Journal Article |

| 2020 | Growth Behavior of Selected Ustilaginaceae Fungi Used for Mannosylerythritol Lipid (MEL) Biosurfactant Production - Evaluation of a Defined Culture Medium Beck, A.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2020 | Factors Affecting the Synthesis of Cellobiose Lipids by Sporisorium scitamineum Oraby, Amira; Werner, Nicole; Sungur, Z.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2020 | A systematic analysis of economic evaluation studies of second-generation biorefineries providing chemicals by applying biotechnological processes Jorissen, T.; Oraby, Amira; Recke, G.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2020 | Chitosan production with larval exoskeletons derived from the insect protein production Hahn, T.; Roth, A.; Ji, R.; Schmitt, E.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2020 | Comparison of Different Lactobacilli Regarding Substrate Utilization and their Tolerance Towards Lignocellulose Degradation Products Gubelt, A.; Blaschke, Lisa; Hahn, Thomas; Rupp, Steffen; Hirth, Thomas; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2020 | Determining different impact factors on the xylonic acid production using Gluconobacter oxydans DSM 2343 Hahn, T.; Torkler, S.; Bolt, R. van der; Gammel, N.; Hesse, M.; Möller, A.; Preylowski, B.; Hubracht, V.; Patzsch, K.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2020 | Current state of chitin purification and chitosan production from insects Hahn, T.; Tafi, E.; Paul, A.; Salvia, R.; Falabella, P.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2020 | Mannosylerythritollipide - mikrobielle Biotenside aus dem Bioreaktor Beck, A.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2019 | Biotechnological and biochemical utilization of lignin Rais, Dominik; Zibek, Susanne |

Aufsatz in Buch Book Article |

| 2019 | Influence of microorganism and plant oils on the structure of mannosylerythritol lipid (MEL) biosurfactants revealed by a novel thin layer chromatography mass spectrometry method Beck, Alexander; Haitz, Fabian; Grunwald, Saskia; Preuss, Laura; Rupp, Steffen; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2019 | Selection and optimization of a suitable pretreatment method for miscanthus and poplar raw material Seibert-Ludwig, Daniel; Hahn, Thomas; Hirth, Thomas; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2019 | Mannosylerythritol Lipids: Biosynthesis, Genetics, and Production Strategies Beck, Alexander; Werner, Nicole; Zibek, Susanne |

Aufsatz in Buch Book Article |

| 2019 | Integrated lignocellulosic value chains in a growing bioeconomy: Status quo and perspectives Dahmen, Nicolaus; Lewandowski, Iris; Zibek, Susanne; Weidtmann, Annette |

Zeitschriftenaufsatz Journal Article |

| 2019 | Stirrer speed adaption is beneficial for liquefaction of cellulose Hahn, Thomas; Nothacker, Matthias; Kövilein, Aline; Beck, Alexander; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2018 | Sewage Polluted Water Treatment via Chitosan. A Review Hahn, Thomas; Zibek, Susanne |

Aufsatz in Buch Book Article |

| 2018 | Chemo-Enzymatic Epoxidation of Lallemantia IbericaSeed Oil Haitz, Fabian; Radloff, S.; Rupp, S.; Fröhling, M.; Hirth, Thomas; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2018 | Entwicklung von Verfahren zur enzymatischen Epoxidierung von Pflanzenölen und Fettsäurederivaten Haitz, F. |

Dissertation Doctoral Thesis |

| 2018 | Unkraut kann auch anders. Handschuhe aus Russischem Löwenzahn Hahn, Thomas; Abele, A.; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2018 | New methods for high-accuracy insect chitin measurement Hahn, T.; Roth, A.; Febel, E.; Fijalkowska, M.; Schmitt, E.; Arsiwalla, T.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2017 | Development of a simplified purification method for a novel formaldehyde dismutase variant from Pseudomonas putida J3 Blaschke, Lisa; Werkmeister, Christina; Wagner, Wenke; Wild, Marion; Gihring, Adrian; Rupp, Steffen; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2017 | Mannosylerythritol- und Cellobioselipide Hahn, T.; Haitz, Fabian; Schäper, N.; Carrillo Riveros, P.; Günther, Michael; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2017 | Draft genome sequence of Pseudonocardia autotrophica strain DSM 43083, an efficient producer of peroxidases for lignin modification Grumaz, Christian; Rais, Dominik; Kirstahler, Philipp; Vainshtein, Yevhen; Rupp, Steffen; Zibek, Susanne; Sohn, Kai |

Zeitschriftenaufsatz Journal Article |

| 2017 | Candida guilliermondii as a potential biocatalyst for the production of long-chain a,o-dicarboxylic acids Werner, Nicole; Dreyer, Miriam; Wagner, Wenke; Papon, Nicolas; Rupp, Steffen; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2017 | Beechwood carbohydrates for enzymatic synthesis of sustainable glycolipids Siebenhaller, S.; Hajek, T.; Muhle-Goll, C.; Himmelsbach, M.; Luy, B.; Kirschhöfer, F.; Brenner-Weiß, G.; Hahn, T.; Zibek, S.; Syldatk, C. |

Zeitschriftenaufsatz Journal Article |

| 2017 | Biotechnological production of bio-based long-chain dicarboxylic acids with oleogenious yeasts Werner, Nicole; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2017 | Verfahren zur Herstellung von Epoxiden mit Hilfe von Enzymen mit Perhydrolaseaktivität Zibek, Susanne |

Patent |

| 2017 | Biotechnological Routes Towards Bio-based Surfactants Schörken, U.; Barbe, S.; Hahn, T.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2017 | Fungal Glycolipids as Biosurfactants Günther, Michael; Zibek, S.; Rupp, S. |

Zeitschriftenaufsatz Journal Article |

| 2017 | Neue Biokatalysatoren zur Herstellung langkettiger Dicarbonsäuren Werner, Nicole; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2017 | Sustainable carbon sources for microbial organic acid production with filamentous fungi Dörsam, S.; Fesseler, J.; Gorte, O.; Hahn, T.; Zibek, S.; Syldatk, C.; Ochsenreither, K. |

Zeitschriftenaufsatz Journal Article |

| 2016 | Scale-up of the chemo-enzymatic epoxidation Haitz, Fabian; Rupp , Steffen; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2016 | Optimization and scale-up of inulin extraction from Taraxacum koksaghyz Hahn, Thomas; Harms, Karsten; Wach, Wolfgang; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2016 | Sustainable enzymatic synthesis of glycolipids in a deep eutectic solvent system Siebenhaller, S.; Muhle-Goll, C.; Luy, B.; Kirschhöfer, F.; Brenner-Weiss, G.; Hiller, Ekkehard; Günther, Michael; Rupp, S.; Zibek, S.; Syldatk, C. |

Zeitschriftenaufsatz Journal Article |

| 2016 | Herstellung langkettiger a,o-Dicarbonsäuren. Mikrobielle Verwertung von nachwachsenden Rohstoffen der zweiten Generation Riepe, Bianca; Vater, Björn; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2016 | pH-driven self-assembly of acidic microbial glycolipids Baccile, Niki; Selmane, Mohamed; Griel, Patrick le; Prévost, Sylvain; Perez, Javier; Stevens, Christian V.; Delbeke, Elisabeth; Zibek, Susanne; Guenther, Michael; Soetaert, Wim; Bogaert, Inge N.A. van; Roelants, Sophie |

Zeitschriftenaufsatz Journal Article |

| 2016 | Fermentative production and characterization of several tailor-made mannosylerythritol lipids Zibek, Susanne; Günther, Michael; Carillo-Riveros, Paula; Hirth, Thomas |

Zeitschriftenaufsatz Journal Article |

| 2016 | Chitin-converting enzymes Moß, K.; Zibek, S.; Hirth, Thomas; Rupp, S. |

Aufsatz in Buch Book Article |

| 2016 | Enzymatische Synthese von Biotensiden aus der Cellulosefraktion des Organosolvprozesses Siebenhaller, Sascha; Hajek, T.; Zibek, Susanne; Syldatk, Christoph |

Zeitschriftenaufsatz Journal Article |

| 2016 | Seasonal pattern of biomass and rubber and inulin of wild Russian dandelion (Taraxacum koksaghyz L. Rodin) under experimental field conditions Kreuzberger, Marie; Hahn, Thomas; Zibek, Susanne; Schiemann, Joachim; Thiele, Katja |

Zeitschriftenaufsatz Journal Article |

| 2016 | ChitoTex - development and production of new insect chitosan and chitosan-based functional coatings for textiles Hahn, Thomas; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2016 | Optimization and scale-up of inulin extraction from Taraxacum kok-saghyz roots Hahn, Thomas; Klemm, Andrea; Zieße, Patrick; Harms, Karsten; Wach, Wolfgang; Rupp, Steffen; Hirth, Thomas; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2015 | Expression of a codon-optimized Carica papaya papain sequence in the methylotrophic yeast pichia pastoris Werner, Nicole; Hirth, Thomas; Rupp, Steffen; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2015 | Lipase-catalyzed epoxidation of fatty compounds and alkenes Haitz, Fabian; Rupp, Steffen; Hirth, Thomas; Zibek, Susanne |

Aufsatz in Buch Book Article |

| 2015 | Transcriptomic profiling of Pseudozyma aphidis during mannosylerythritol lipid synthesis Günther, Michael; Grumaz, Christian; Lorenz, Stefan; Stevens, Philip; Lindemann, Elena; Hirth, Thomas; Sohn, Kai; Zibek, Susanne; Rupp, Steffen |

Zeitschriftenaufsatz Journal Article |

| 2015 | Enzymatic hydrolysis of solid substrates: Critical notes and experimental guidelines for improvements Hahn, Thomas; Haitz, Fabian; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2015 | Development of new biocatalysts and process optimization for the production of long-chain a,o-dicarboxylic acids Werner, Nicole; Riepe, Bianca; Vater, Björn; Geiger, Georg; Hirth, Thomas; Rupp, Steffen; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2015 | Integrierte Bioproduktion - Pflanzliche Öle für die chemische Industrie Torkler, Sandra; Haitz, Fabian; Zibek, Susanne; Patzsch, Katja; Hirth, Thomas |

Zeitschriftenaufsatz Journal Article |

| 2015 | Enzymatische Verzuckerung von Lignozellulose Vater, Björn; Hirth, Thomas; Rupp, Steffen |

Zeitschriftenaufsatz Journal Article |

| 2015 | Draft genome sequence of Amantichitinum ursilacus IGB-41, a new chitin-degrading bacterium Kirstahler, Philipp; Günther, Michael; Grumaz, Christian; Lindemann, Elena; Rupp, Steffen; Zibek, Susanne; Sohn, Kai |

Zeitschriftenaufsatz Journal Article |

| 2015 | The transcriptomic profile of Pseudozyma aphidis during production of mannosylerythritol lipids Günther, Michael; Grumaz, Christian; Lorenz, Stefan; Stevens, Philip; Lindemann, Elena; Hirth, Thomas; Sohn, K.; Zibek, S.; Rupp, S. |

Zeitschriftenaufsatz Journal Article |

| 2015 | Vom Schüttelkolben in die Pilotanlage: Enzymherstellung in Hefen Werner, Nicole; Vater, B.; Elter, T.; Patzsch, K.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2015 | Identification of new CALB-type lipases within the genus Pseudozyma Sabatini, Selina; Schultz, Elisabeth; Helber, Nicole; Rupp, Steffen; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2014 | Entwicklung neuer Biokatalysatoren für die Herstellung von langkettigen Dicarbonsäuren Helber, Nicole; Rupp, Steffen; Hirth, Thomas; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2014 | Neue Verfahren für die Ligninmodifikation am Beispiel der Natur Zibek, Susanne; Rais, Dominik; Rupp, Steffen; Hirth, Thomas |

Zeitschriftenaufsatz Journal Article |

| 2014 | Herstellung biozertifizierter Kosmetika aus nachwachsenden Rohstoffen Vásquez-Caicedo, Ana Lucia; Zibek, Susanne; Rupp, Steffen; Egner, Siegfried |

Zeitschriftenaufsatz Journal Article |

| 2014 | Enzymatische Verzuckerung von Lignozellulose Vater, Björn; Hirth, Thomas; Rupp, Steffen |

Zeitschriftenaufsatz Journal Article |

| 2014 | Optimierung und Scale-up der enzymatischen Hydrolyse inkl. Ligninabbau Tippkötter, Nils; Duwe, Anna; Rais, Dominik; Zibek, Susanne; Zorn, H. |

Zeitschriftenaufsatz Journal Article |

| 2014 | Synthese von Mannosylerythritollipide von Pseudozyma-Spezies mit nachwachsenden Rohstoffen Zibek, Susanne; Hirth, Thomas; Rupp, Steffen; Carrillo Riveros, Paula Alejandra |

Zeitschriftenaufsatz Journal Article |

| 2014 | Integrierte Bioproduktion - Integrierte chemisch-biotechnologische Herstellung von Synthesebausteinen auf der Basis pflanzlicher Öle Zibek, Susanne; Rupp, Steffen; Hirth, Thomas |

Zeitschriftenaufsatz Journal Article |

| 2014 | Demonstration der fermentativen Herstellung von Isobuten im Pilotmaßstab Elter, Tino; Buhl, T. |

Zeitschriftenaufsatz Journal Article |

| 2014 | Identifizierung neuer bakterieller Lignin-modifizierender Enzyme Zibek, Susanne; Rais, Dominik; Rupp, Steffen; Hirth, Thomas |

Zeitschriftenaufsatz Journal Article |

| 2014 | Neue Enzyme für eine Methanol-basierte grüne Chemie Zibek, Susanne; Blaschke, Lisa; Hirth, Thomas; Rupp, Steffen |

Zeitschriftenaufsatz Journal Article |

| 2014 | High solids enzymatic hydrolysis of pretreated lignocellulosic materials with a powerful stirrer concept Ludwig, D.; Buchmann, M.; Hirth, Thomas; Rupp, S.; Zibek, S. |

Zeitschriftenaufsatz Journal Article |

| 2014 | Herstellung von Enzymen - Maßstabsübertragung vom Laborprozess zur Pilotanlage Helber, Nicole; Vater, Björn; Haitz, Fabian; Torkler, Sandra; Patzsch, Katja; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

| 2014 | Genome sequence of the basidiomycetous fungus Pseudozyma aphidis DSM70725, an efficient producer of biosurfactant mannosylerythritol lipids Lorenz, Stefan; Günther, Michael; Grumaz, Christian; Rupp, Steffen; Zibek, Susanne; Sohn, Kai |

Zeitschriftenaufsatz Journal Article |

| 2013 | Lignin als nachwachsende Rohstoffquelle Staiger, Nadine; Hirth, Thomas; Rupp, Steffen; Zibek, Susanne |

Zeitschriftenaufsatz Journal Article |

Diese Liste ist ein Auszug aus der Publikationsplattform Fraunhofer-Publica

This list has been generated from the publication platform Fraunhofer-Publica

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB