Jahr

Year | Titel/Autor:in

Title/Author | Publikationstyp

Publication Type |

|---|

| 2025 |

Molecular Identification of Human and Plant Pathogens in Municipal Domestic Wastewater for Hydroponic System Applications

Kriem, Lukas Simon; King, Neil; Niemann, Sinja; Vainshtein, Yevhen; Sonntag, Mirko |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Challenges and requirements of AI-based waste water treatment systems

Dalibard, Antoine; Kriem, Lukas Simon; Beckett, Marc; Scherle, Stephan; Yeh, Yen-Cheng; Schließmann, Ursula |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

A Low-Tech Approach to Mobilize Nutrients from Organic Residues to Produce Bioponic Stock Solutions

Heintze, Sebastian; Beckett, Marc; Germer, Jörn U.; Kriem, Lukas; Asch, Folkard |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Design and Implementation of Energy-Water Nexus Management in a Solar-Powered NFT Hydroponic System

Sidibé, Abdoulaye; Ndeda, Rehema; Murimi Nyamu Wanjiru, Evan; Mutwiwa, Urbanus N.; Kriem, Lukas; Beckett, Marc; Fischer, Peter |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Nanocrystalline apatites: Post-immersion acidification and how to avoid it - application to antibacterial bone substitutes

Drouet, Christophe; Vandecandelaère, Nicolas; Burger-Kentischer, Anke; Trick, Iris; Kohl, Christina; Maucher, Tanja; Müller, Michaela; Weber, Franz |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Smart mobile vaccination pickup for sustainable improvement of medical care and smart pandemic control in Southern Africa

Stortz, Felix; Went, Joachim; Koschikowski, Joachim; Maruf, Md Nasimul Islam; Schäfer, Lothar; Neumann, Frank; Lotz, Bryan; Beckett, Marc; Hamann, Maike |

Konferenzbeitrag

Conference Paper

|

| 2021 |

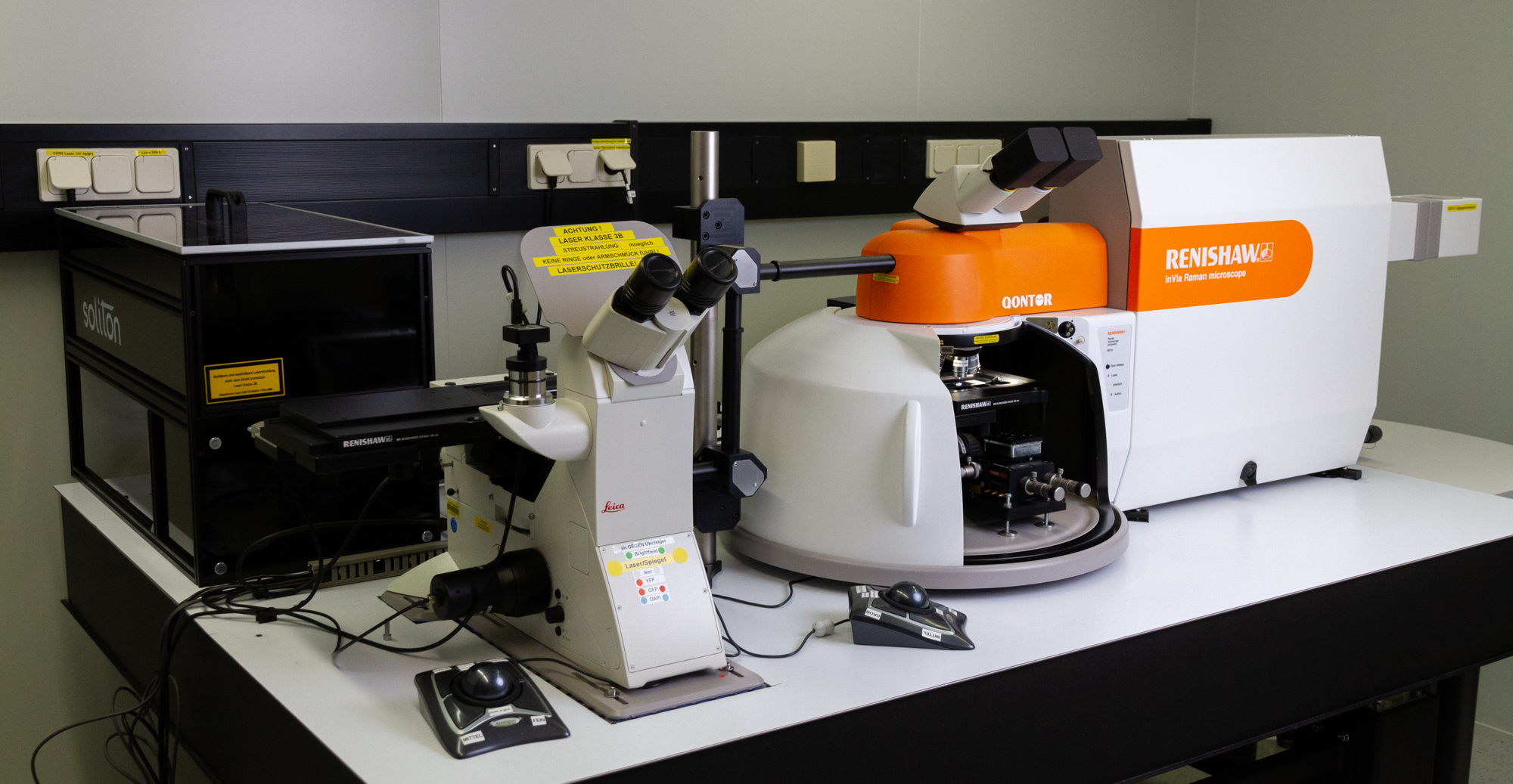

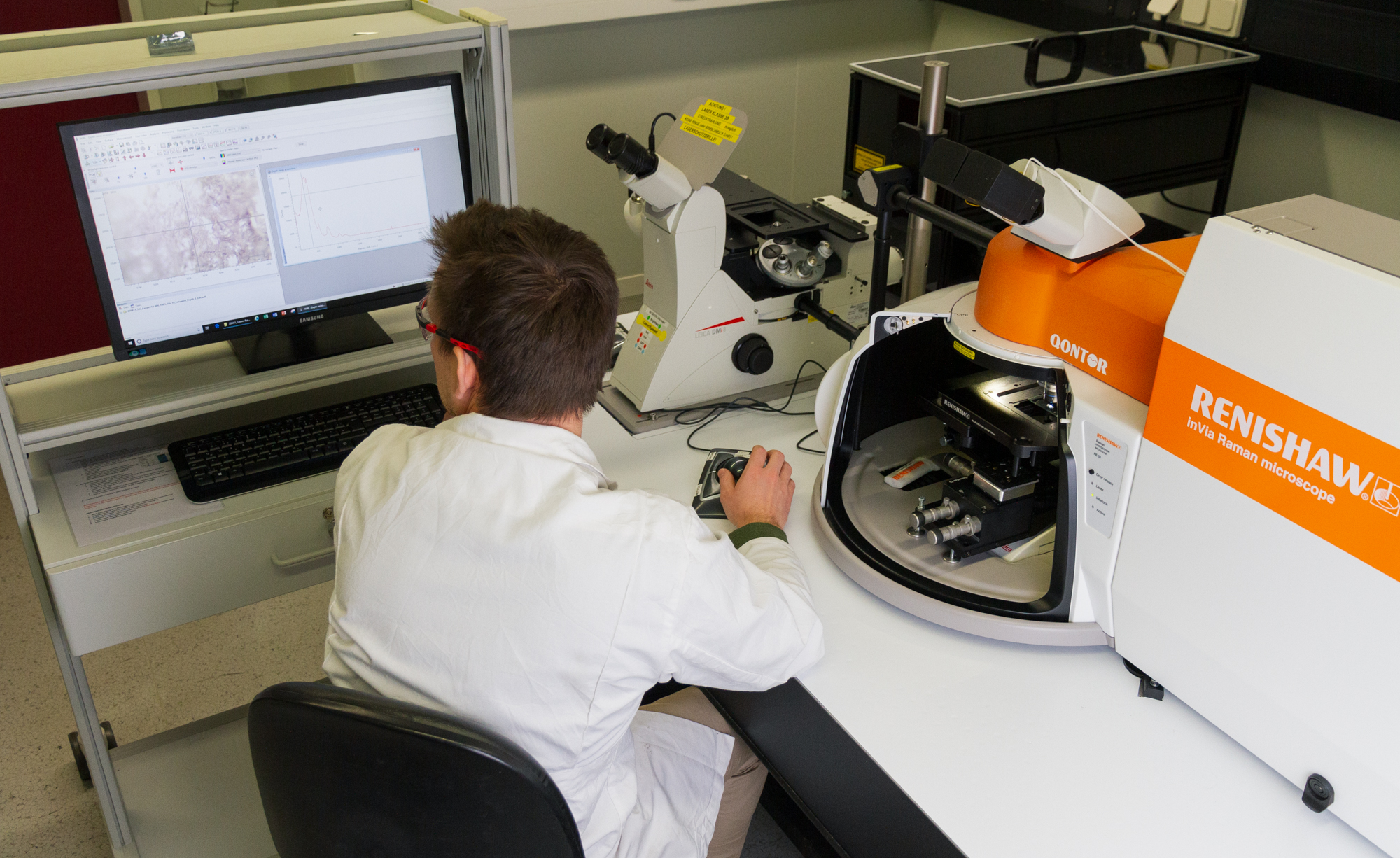

Mapping of a Subgingival Dual-Species Biofilm Model Using Confocal Raman Microscopy

Kriem, L.S.; Wright, K.; Ccahuana-Vasquez, R.A.; Rupp, S. |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

Confocal Raman microscopy to identify bacteria in oral subgingival biofilm models

Kriem, L.S.; Wright, K.; Ccahuana-Vasquez, R.A.; Rupp, S. |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

Assuring water quality along multi-barrier treatment systems for agricultural water reuse

Mohr, Marius; Dockhorn, Thomas; Drewes, Jörg E.; Karwat, Sybille; Lackner, Susanne; Lotz, Bryan; Nahrstedt, Andreas; Nocker, Andreas; Schramm, Engelbert; Zimmermann, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2018 |

Teilvorhaben: Automatisierte Biosensoren, selbstlernende Monitoring-Tools und Konzepte für sichere Sensornetzwerke zur Erhöhung der Resilienz von Trinkwasserinfrastrukturen

Bernard, Thomas; Burger-Kentischer, Anke; Frick, Konstantin; Jacubasch, Andreas; Kerger, Christian; Kohl, Christina; Kühnert, Christian; Meier, David; Trick, Iris |

Bericht

Report

|

| 2017 |

Augmented resilience of water distribution systems following severe abnormal events

Piller, O.; Sedehizade, F.; Bernard, Thomas; Braun, M.; Cheifetz, N.; Deuerlein, J.; Wagner, M.; Lapebie, E.; Trick, Iris; Weber, J.-M.; Werey, C. |

Vortrag

Presentation

|

| 2016 |

On-line monitoring of drinking water based on a biological broad-spectrum sensor

Bernard, Thomas; Jacubasch, Andreas; Trick, Iris; Burger-Kentischer, Anke; Kohl, Christina |

Poster

|

| 2015 |

Control of drinking water by linking biosensors with physicochemical methods

Cimalla, Volker; Hugger, Stefan; Fuchs, Frank; Anzt, Johannes; Bitterling, Moritz; Yang, Nianjun; Kohl, Christina; Maucher, Tanja; Mühlemeier, Ilka; Burger-Kentischer, Anke; Trick, Iris |

Zeitschriftenaufsatz

Journal Article

|

| 2015 |

Direct generation of titanium dioxide nanoparticles dispersion under supercritical conditions for photocatalytic active thermoplastic surfaces for microbiological inactivation

Zydziak, Nicolas; Ambrosio Zanin, Maria-Helena; Trick, Iris; Hübner, Christof |

Zeitschriftenaufsatz

Journal Article

|

| 2014 |

Enzyme-functionalized biomimetic apatites: Concept and perspectives in view of innovative medical approaches

Weber, Christina G.; Müller, Michaela; Vandecandelaere, Nicolas; Trick, Iris; Burger-Kentischer, Anke; Maucher, Tanja; Drouet, Christophe |

Zeitschriftenaufsatz

Journal Article

|

| 2012 |

Multicentre trials for decontamination of fine-lumen PTFE tubes loaded with bacterial endospores by low and atmospheric pressure plasma

Schnabel, U.; Maucher, Tanja; Köhnlein, J.; Volkwein, W.; Niquet, R.; Trick, Iris; Stieber, M.; Müller, Michael; Werner, H.P.; Ehlbeck, J.; Oehr, Christian; Weltmann, K.D. |

Zeitschriftenaufsatz

Journal Article

|

| 2012 |

Strategien gegen Mikroorganismen an Kunststoffoberflächen

Trick, Iris |

Aufsatz in Buch

Book Article

|

| 2012 |

Flexible survival strategies of Pseudomonas aeruginosa in biofilms result in increased fitness compared to Candida albicans

Purschke, F.G.; Hiller, Ekkehard; Trick, Iris; Rupp, S. |

Zeitschriftenaufsatz

Journal Article

|

| 2012 |

Flexible survival strategies of Pseudomonas aeruginosa in biofilms result in increased fitness compared with Candida albicans

Purschke, F.G.; Hiller, Ekkehard; Trick, Iris; Rupp, S. |

Zeitschriftenaufsatz

Journal Article

|

| 2012 |

Vermeidung von Biofilm und Unterdrückung von Virulenzfaktoren pathogener Mikroorganismen an Grenzflächen

Müller, Michaela; Kohl, Christina; Kerger, Christian; Burger-Kentischer, Anke; Trick, Iris; Hirth, Thomas |

Zeitschriftenaufsatz

Journal Article

|

| 2011 |

Assembly of standardized test specimen for microbial quantification of plasma sterilization processes of fine PTFE tubes as used in thermo sensitive medical devices like flexible endoscopes

Maucher, Tanja; Schnabel, U.; Volkwein, W.; Köhnlein, J.; Winter, J.; Weltmann, K.-D.; Trick, Iris; Oehr, Christian |

Zeitschriftenaufsatz

Journal Article

|

| 2011 |

Breitband-Biosensor AquaBioTox zur onlinefähigen Trinkwasserüberwachung

Bernard, Thomas; Müller, Thomas; Jacubasch, Andreas; Schuchert, Tobias; Burger-Kentischer, A.; Maucher, T.; Geiger, Georg-Ullrich; Trick, Iris; Sedehizade, F. |

Konferenzbeitrag

Conference Paper

|

| 2011 |

Biofilmvermeidung durch natürliche Wirkstoffe - gezielte und langfristige Freisetzung durch ein PEG-basiertes Depotsystem

Weber, Christina; Burger-Kentischer, Anke; Müller, Michaela; Trick, Iris; Hirth, Thomas |

Zeitschriftenaufsatz

Journal Article

|

| 2010 |

Communication in biofilms between different species: Candida albicans and Pseudomonas aeruginosa

Purschke, F.; Burger-Kentischer, A.; Rupp, S.; Trick, Iris; Hirth, Thomas |

Konferenzbeitrag

Conference Paper

|

| 2009 |

Onlinefähige Trinkwasserüberwachung auf Grundlage eines biologischen Breitbandsensors mit automatischer Bildauswertung (AquaBioTox)

Sedehizade, F.; Trick, Iris; Bernard, T.; Burger-Kentischer, A.; Maucher, T.; Geiger, Georg-Ullrich; Kuntze, H.-B.; Müller, T.; Sawo, F.; Moldaenke, C. |

Konferenzbeitrag

Conference Paper

|

| 2008 |

Clinical tracheal replacement: transplantation, bioprostheses and artificial grafts

Steger, V.; Hampel, M.; Trick, Iris; Müller, Michael; Walles, T. |

Zeitschriftenaufsatz

Journal Article

|

| 2007 |

Physikalisch-chemische und mikrobiologische Wirkung gesputterter photokatalytischer Titanoxid-Schichten

Frach, P.; Glöß, D.; Vergöhl, M.; Hund-Rinke, K.; Trick, Iris |

Zeitschriftenaufsatz

Journal Article

|

| 2007 |

Anaerobe Reinigung von Abwasser

Sternad, W.; Mohr, M.; Spork, C.; Trösch, W.; Trick, I.; Krischke, W. |

Patent

|

| 2006 |

Decomposition ability and bioactivity of photocatalytic TiO2 based layers prepared by reactive pulse magnetron sputtering

Frach, P.; Glöß, D.; Zywitzki, O.; Vergöhl, M.; Neumann, F.; Hund-Rinke, K.; Trick, Iris |

Konferenzbeitrag

Conference Paper

|

| 2003 |

Verfahren zur Erhoehung der Verwendungszeit von Kuehlschmierstoffen

Krueger, K.; Mehlstaeubl, J.; Sternad, W.; Trick, I. |

Patent

|

| 2003 |

Ultrathin antibacterial polyammonium coatings on polymer surfaces

Thome, J.; Holländer, A.; Jaeger, W.; Trick, Iris; Oehr, Christian |

Konferenzbeitrag

Conference Paper

|

| 2001 |

Plasma treatment - an increasing technology for paper restoration?

Vohrer, Uwe; Trick, Iris; Bernhardt, J.; Oehr, Christian; Brunner, H. |

Zeitschriftenaufsatz

Journal Article

|

| 2000 |

Stopp dem Buchzerfall

Koch, B.; Trick, Iris; Vohrer, Uwe |

Zeitschriftenaufsatz

Journal Article

|

| 2000 |

Mikroorganismen. Ursache für die Zerstörung von Archivalien und Büchern

Trick, Iris; Vohrer, Uwe |

Zeitschriftenaufsatz

Journal Article

|

| 1999 |

Bioaerosole - Monitoring mit einem neuartigen Partikelzähler

Schüle, A.; Kölblin, R.; Grimme, R.; Trick, Iris |

Zeitschriftenaufsatz

Journal Article

|

| 1999 |

Stop dem Buchverfall

Vohrer, Uwe; Trick, Iris |

Zeitschriftenaufsatz

Journal Article

|

| 1999 |

Entwicklung neuer Sterilisationsverfahren mittels der Plasmatechnik

Vohrer, Uwe; Trick, Iris; Oehr, Christian |

Zeitschriftenaufsatz

Journal Article

|

| 1999 |

Echtzeit-Differenzierung von luftgetragenen biotischen und abiotischen Partikeln

Schüle, A.; Grimme, R.; Trick, Iris |

Zeitschriftenaufsatz

Journal Article

|

| 1998 |

Detection of Biological Contamination

Grimme, R.; Kölblin, R.; Schüle, A.; Trick, Iris |

Konferenzbeitrag

Conference Paper

|

| 1998 |

Gefahr aus der Luft: On-line-Differenzierung von luftgetragenen biotischen und abiotischen Partikeln

Kölblin, R.; Trick, Iris; Grimme, R. |

Zeitschriftenaufsatz

Journal Article

|

| 1997 |

Optimierung von Dichtsystemen

Schnepple, H.; Reuter, G.; Trick, Iris; Trösch, Walter |

Zeitschriftenaufsatz

Journal Article

|

| 1996 |

Plasmatechnologie in der Restaurierung

Vohrer, Uwe; Anders, M.; Trick, Iris; Oehr, Christian |

Zeitschriftenaufsatz

Journal Article

|

| 1994 |

Entwicklung von Membranen und Membrantechniken nach dem Vorbild der Natur. Vortrag im Rahmen der Informationsveranstaltung der Ministerin für Natur und Umwelt des Landes Schleswig-Holstein am 6.7.1994 in Kiel

Trick, Iris |

Tagungsband

Conference Proceeding

|

| 1991 |

Comparative investigations on the production of glutamic acid with Corynebacterium glutamicum in stirred tank and propeller loop reactors

Reuter, G.; Gebicke, W.; Chmiel, H.; Johl, H.-J.; Sternad, W.; Trick, Iris; Trösch, Walter |

Aufsatz in Buch

Book Article

|

| 1990 |

Characterization of bioreactors with three biological systems

Krischke, W.; Schmid, U.; Wessling, V.; Chmiel, H.; Henkel, H.-J.; Sternad, W.; Trick, Iris; Trösch, Walter; Trück, U. |

Konferenzbeitrag

Conference Paper

|

| 1989 |

Immunenzymatischer Test mit Detektion durch Farbumschlag im sichtbaren Spektralbereich

Bryniok, D.; Trick, I.; Trösch, W. |

Patent

|

| 1989 |

Abwasserreinigung mit immobilisierten Mirkoorganismen unter Verwendung von porösen, kugeligen Sinterglasträgern

Henkel, H.-J.; Schneider, W.; Sternad, W.; Trick, Iris; Trösch, Walter |

Konferenzbeitrag

Conference Paper

|

| 1989 |

Purification of waste waters using microorganisms immobilized of spherical particles of porous sintered glass material

Henkel, H.-J.; Schneider, W.; Sternad, W.; Trick, Iris; Trösch, Walter |

Konferenzbeitrag

Conference Paper

|

| 1987 |

Immunoenzymatic quantitation of methanogenic bacteria in anaerobic mixed cultures

Bryniok, Dieter; Trick, Iris; Trösch, Walter |

Konferenzbeitrag

Conference Paper

|

| 1987 |

Quantitativer immunenzymatischer Nachweis von methanogenen Bakterien in Mischkulturen

Bryniok, Dieter; Trick, Iris; Trösch, Walter |

Konferenzbeitrag

Conference Paper

|

| 1985 |

Aerobic spore-forming bacteria as detrimental infectants in plant tissue cultures

Trick, Iris; Lingens, F. |

Zeitschriftenaufsatz

Journal Article

|

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB