In the HoLaFlor project, the operation of a biogas plant in a high-load process was realized on a pilot plant scale and compared with a reference plant with conventional long retention time. We were able to show that biogas plants with significantly shorter retention times can be realized using suitable plant technology and that methane productivity can thus be two to four times higher than in conventional operation with long retention times.

HoLaFlor – Increasing the efficiency of biogas plants by establishing high-load digestion

In 2016 there were more than 8500 biogas plants in Germany that use renewable raw materials as substrates. These biogas plants are usually operated with hydraulic retention times of 40 days. Significantly longer hydraulic dwell times of up to 90 days are also not uncommon. In the course of the energy turnaround, the aim is to further increase the share of biogas in renewable energies.

Objectives: Biogas plants as a high-load digestion in lab scale using maize as substrate

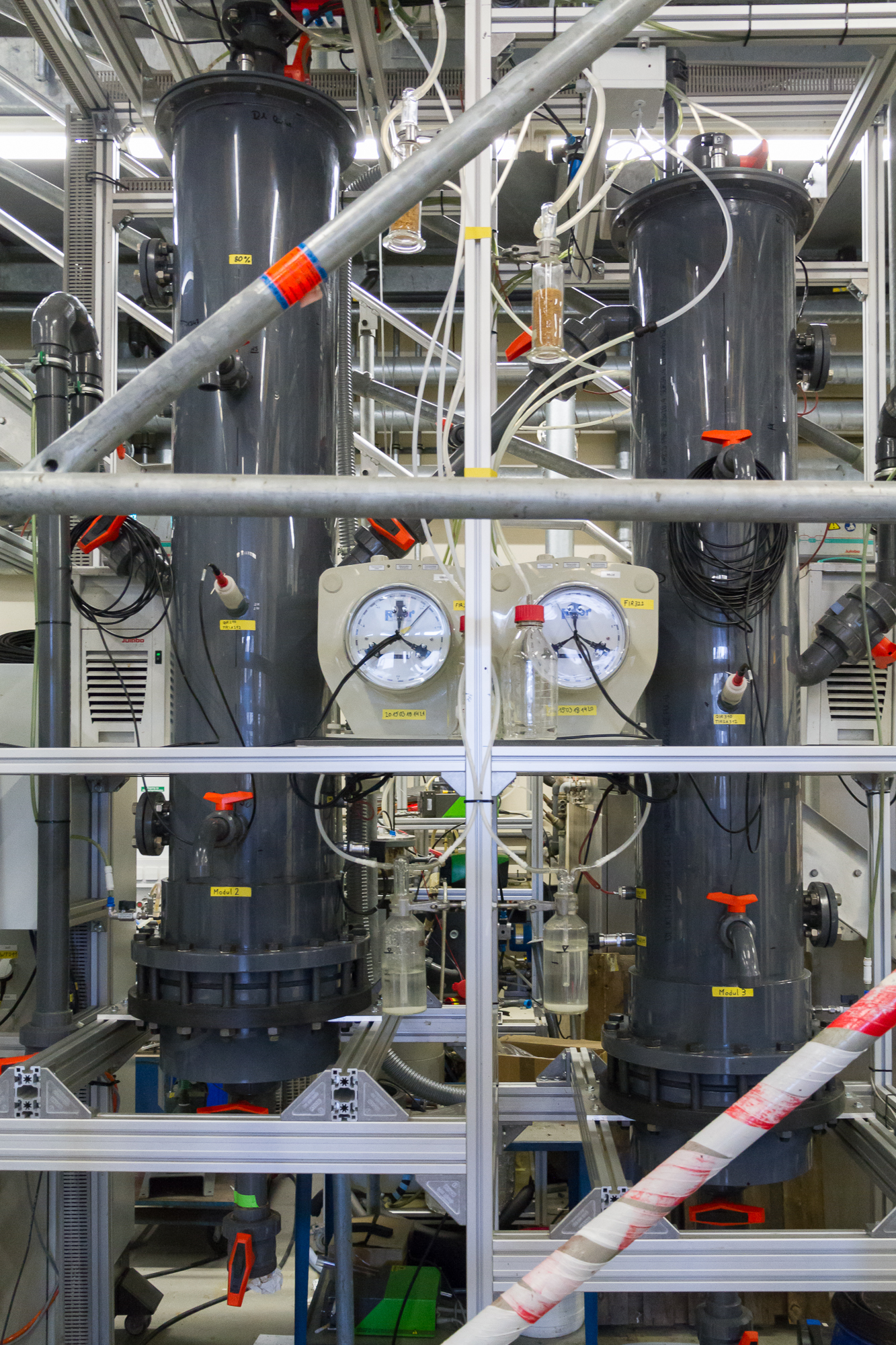

The aim of the HoLaFlor research project was therefore to operate a biogas plant with shorter retention times at constant biogas rates and at the same time to increase methane productivity. In the project, the operation of a high-load biogas plant on a pilot plant scale with proof of an increased degradation capacity and characterization of the microorganism flora had to be realized. For this purpose, a further pilot plant with conventional processes (long retention time) was operated in parallel as a reference. The analysis of the microorganism flora in the biogas plants was carried out in a comparative manner for both modes of operation.

Subsequently, the influence of bovine slurry as a co-substrate for both modes of operation was investigated comparatively. Fermentation with short retention times (high-load process) for use with renewable raw materials was tested both for maize silage as a mono-substrate and for maize silage with bovine slurry as a co-substrate, and the influence on the composition of the microorganism flora was characterized.

Results: Investigation of increase in efficiency

For a pilot-scale biogas plant with maize silage as monosubstrate, short retention times of between 15 and 30 days and corresponding organic loading rates of between 2.9 and 5.8 g/L*d were achieved at Fraunhofer IGB. At the same time, the conventional process with a retention time of 70 days was investigated in a reference plant. It was shown that the methane productivity could be increased from 0.9 NL/L*d to 1.7 NL/L*d with increasing throughput for retention times of 15 to 30 days, without significant losses in the methane yield. The corresponding methane yield was between 284 NL/kg TVS and 303 NL/kg TVS. In comparison, a productivity of only 0.4 NL/L*d was achieved in the reference plant with a retention time of 70 days. The methane yield amounted 341 NL/kg TVS.

The results impressively prove that biogas plants using suitable plant technology can be operated with significantly shorter retention times and thus methane productivities can be achieved which are two to four times higher than with conventional process and long retention times.

Project information

Project title

HoLaFlor – Biogas plant as a high-load digestion in lab scale using maize as substrate: Investigation of increase in efficiency and the microbial population

Project duration

October 2015 – December 2018

Project partners

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, Stuttgart, Germany (Coordination)

Funding

We would like to thank the German Federal Ministry of Food and Agriculture (BMEL) for funding the project “HOLAFLOR – Biogas plant as a high-load digestion in lab scale using maize as substrate: Investigation of increase in efficiency and the microbial population, promotional reference FKZ 22011613.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB