So far, the industrial use of technical separation membranes has been largely set to liquid filtration and less to gas separation. In the MEGA project, mixed‑matrix membranes were developed at the Fraunhofer IGB in cooperation with three other Fraunhofer institutes, which have great potential for gas separation due to their improved separation properties compared to pure polymer coatings.

MAVO MEGA – Functional membranes for save and energy efficient gas separation

Up to now, the industrial use of technical membranes has been mainly focused on liquid filtration and less on gas separation. In the MEGA project, mixed-matrix membranes were developed at Fraunhofer IGB in cooperation with three other Fraunhofer institutes. These membranes have great potential for gas separation due to improved separation properties compared to pure polymer coatings.

Mixed-matrix composite membranes for gas separation

The industrial use of technical separation membranes has so far been predominantly limited to liquid filtration. The main reasons for this are inadequate separation properties and high membrane costs. However, membranes with their inherent energy efficiency offer enormous potential also for the separation of gases.

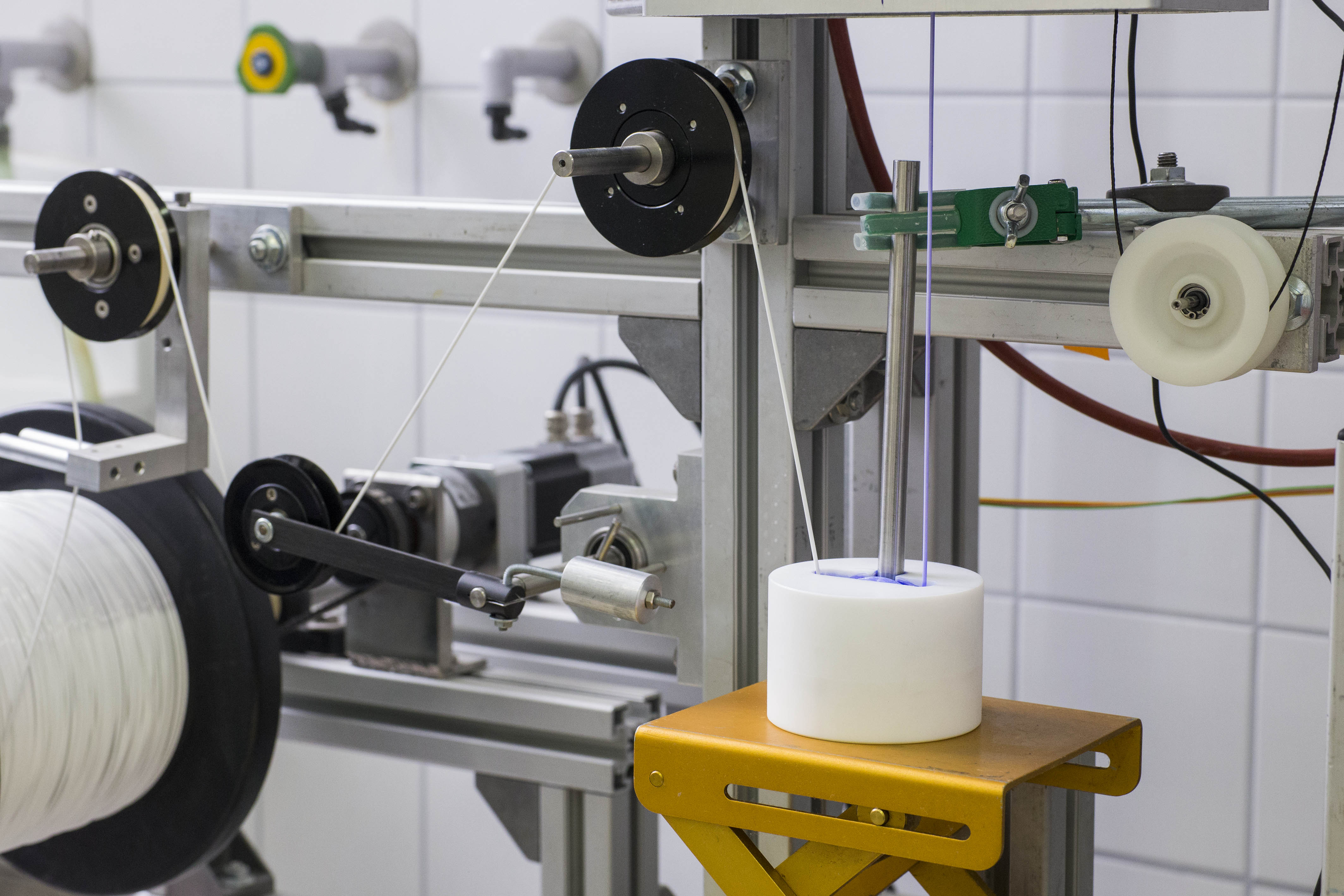

In the MEGA project, mixed-matrix membranes were developed that are suitable for gas separation due to their specific structure. For this purpose, microporous framework compounds (zeolites, MOFs), which have defined pore sizes and are thus suitable for the separation of gas molecules via size, were embedded in polymer matrices. For this purpose, porous PVDF hollow fiber membranes were dip-coated with the corresponding mixed-matrix dispersions. The viscosity of the dispersion and the coating speed were used to control the thickness of the mixed-matrix layer in the range from 500 nm to 5 µm. The use of nanoparticulate framework compounds (< 100 nm) is crucial for the quality of the coatings. By controlling the thickness of the layer, only small amounts of material are required for the coating.

The mixed-matrix membranes show improved separation properties compared to pure polymer coatings. For example, the water vapor permeability of polyvinyl alcohol coatings was increased by almost 100 percent to 7000 barrers by adding SAPO-34 particles. By selecting suitable polymer-MOF combinations, the separation properties of the membranes can be adapted to other problems, such as the separation of CO2 from exhaust gases.

Project information

Project title

MAVO MEGA – Functional membranes for save and energy efficient gas separation

Project duration

January 2017 – December 2019

Project partners

- Fraunhofer Institute for Ceramic Technologies and Systems IKTS (Coordination)

- Fraunhofer Institute for Applied Polymer Research IAP

- Fraunhofer Institute for Environmental, Safety, and Energy Technology UMSICHT

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB