Crosslinkable polymers for stable coatings

We have developed a variety of different polymers for the wet chemical coating of membranes. These polymers are thermally or photochemically crosslinkable and therefore the resulting coatings are stable in the long term.

In this way, we can provide coatings with hydrophilic to hydrophobic properties or introduce functional groups (e.g. amines) that serve as a basis for further chemical modifications.

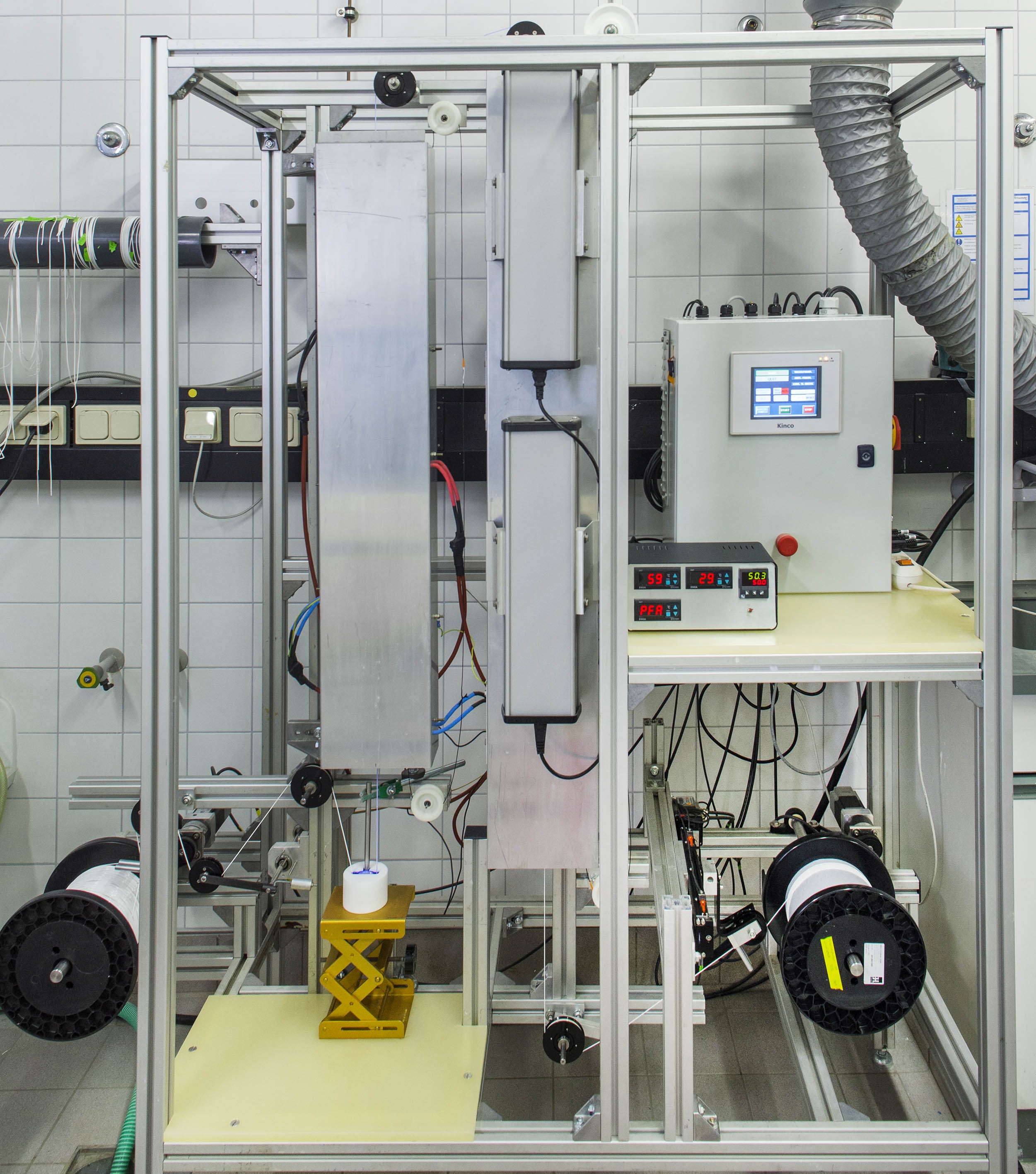

Continuous roll-to-roll coating

At Fraunhofer IGB we have the infrastructure to produce continuous roll-to-roll coatings for both hollow fiber and flat membranes.

By controlling the wetting properties of the membranes, it is possible to control whether the coating is on the surface of the membrane or inside the pores. Furthermore, there are coating systems that are also suitable for coating inside hollow fibers. In addition to polymer coating, we also have other technologies at our disposal, such as interfacial polymerization or grafting.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB