The overall objective of the "MegaLyseurPlus" joint project was to optimize the overall "electrolysis plant" system and to create the conditions for the development and operation of future large-scale electrolysis systems. To this end, the infrastructure for characterizing ionomer membranes was developed and set up at the IGB. A test rig was set up to determine the gas crossover of ionomer membranes, and methods were established for the targeted contamination and regeneration of ionomer membranes with metal ions.

MegaLyseurPlus – Development, design and construction of a modular, innovative and cost-efficient PEM electrolysis system of 1.25 MW with downstream compression plant

The overall objective of the joint project "MegaLyseurPlus" was to optimize the overall system "electrolysis plant" and to create the prerequisites for the development and operation of future large-scale electrolysis systems. The focus is on the HYPOS guiding principle of creating the prerequisites for the economic use of green hydrogen as an energy carrier of the future by the end of the BMBF funding program "Twenty20 - Partnership for Innovation". While it appears that the essential components of an electrolysis plant are already commercially available and potentially scalable on their own, it must be noted that operation in the electrolysis environment poses special requirements. The particular challenge here arises from the tension between highly fluctuating energy input (e.g. in the case of a direct coupling with a wind farm) and the continuous hydrogen demand of a large number of industrial processes or the integration of such a large-scale electrolysis system into a storage infrastructure for base-load capable energy storage and system-serving energy supply. Partial load capability and dynamics of essential components as well as the interface design for infrastructure integration have to be mentioned in particular, while the nominal overall efficiency as well as the specific costs have to be kept in view. Optimized subcomponents and system solutions are urgently needed here in order to successfully complete sector coupling, to integrate renewable energies stably into the national energy system and to advance the decarbonization of industry. With all these system-level aspects, however, it must not be disregarded that even with scaling of the system size, further development work remains necessary at the cell stack level in order to achieve further, necessary production cost reductions.

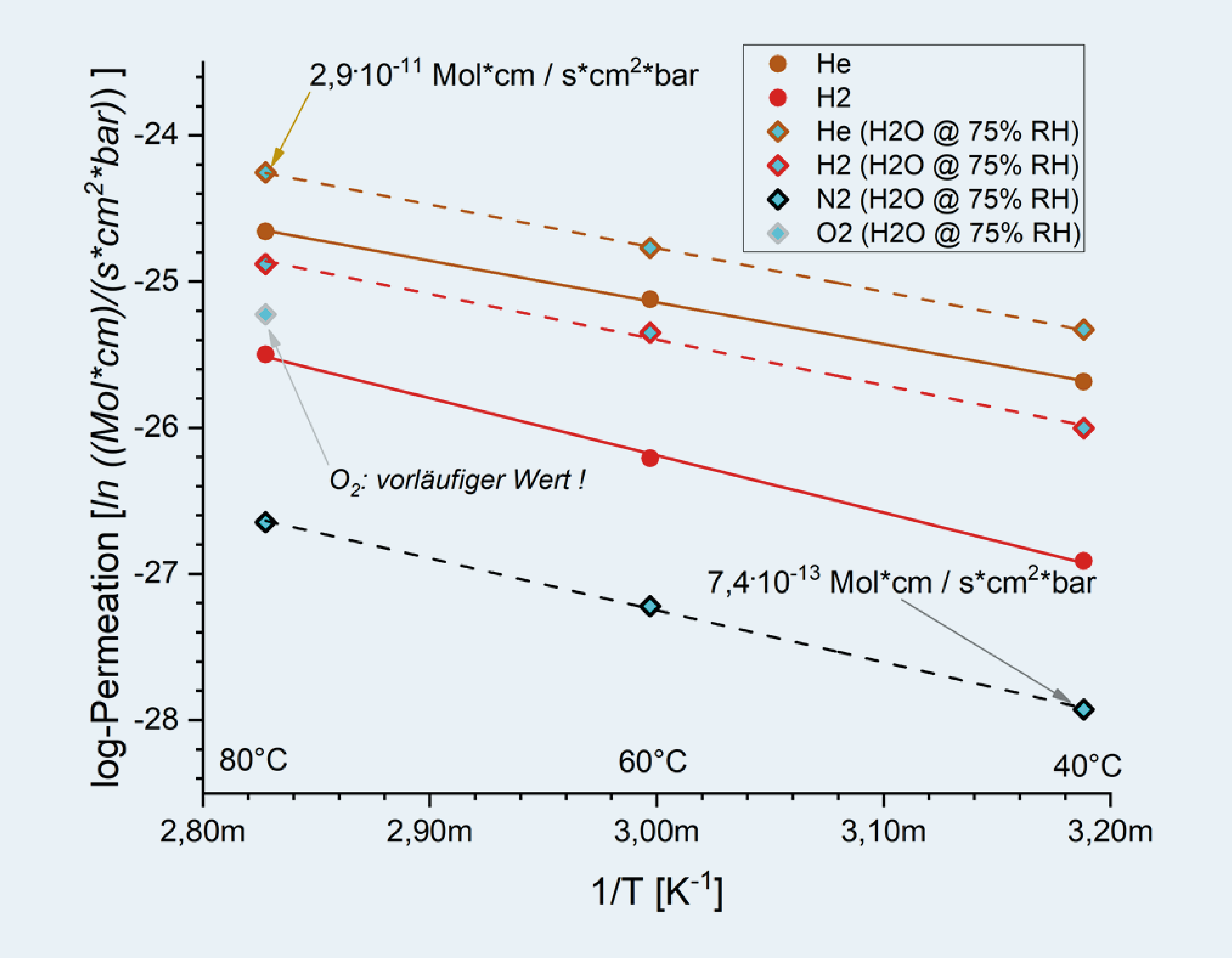

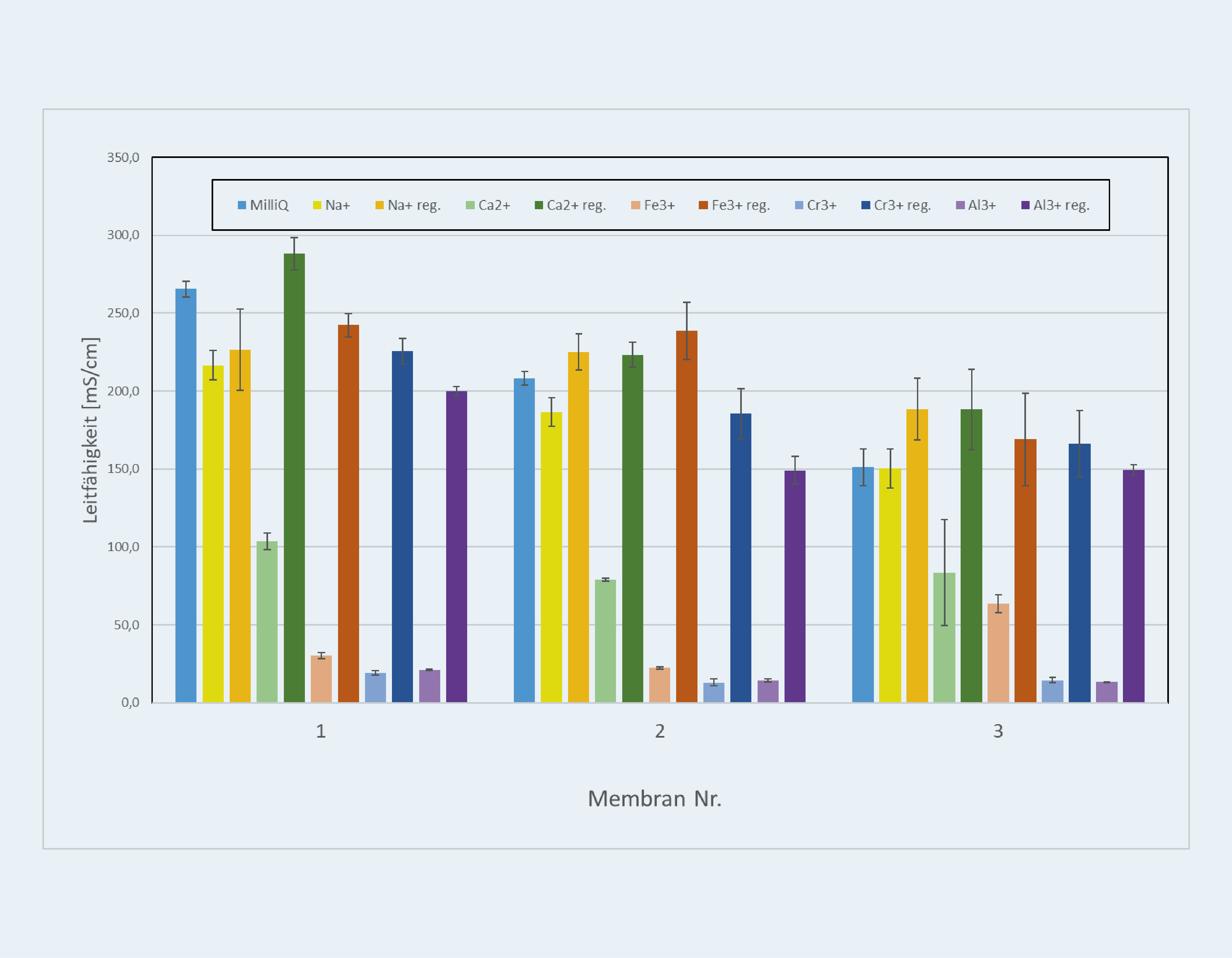

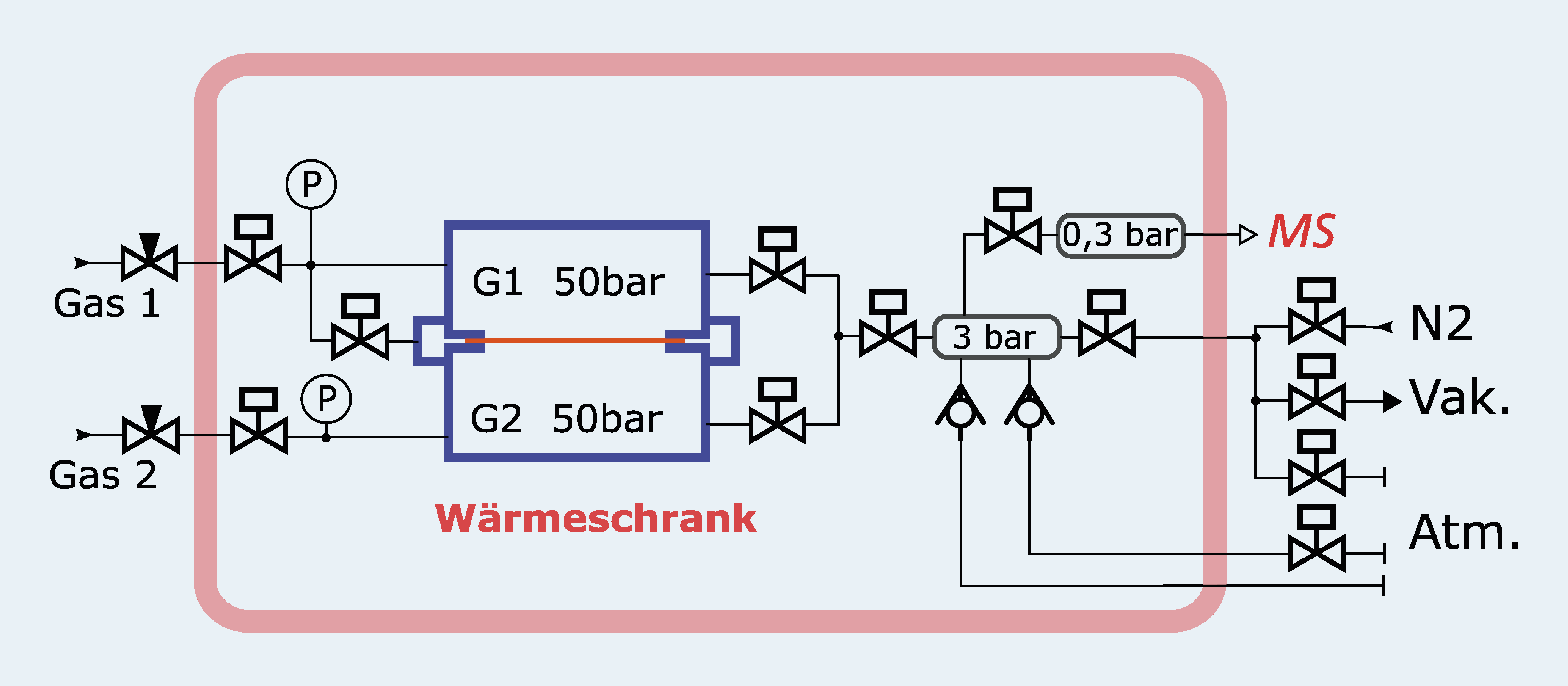

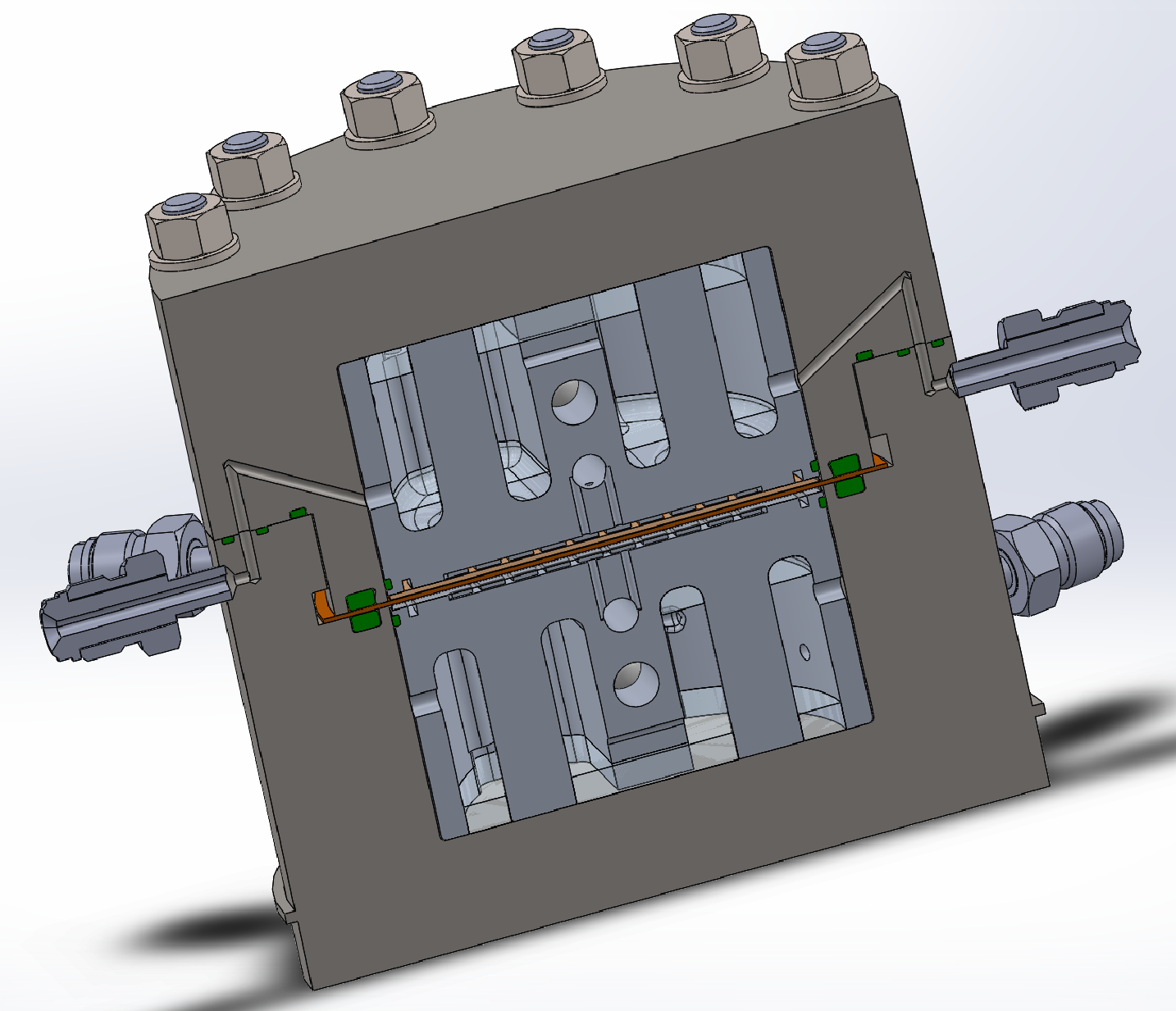

At the IGB, the infrastructure for the characterization of ionomer membranes in particular was developed and established in close cooperation with the CBP. Existing methods, such as the determination of ion exchange capacity, ion conductivity and swelling behavior, were validated within the project. In addition, a test rig was set up to determine the gas crossover of ionomer membranes (see Fig. 1-4). Furthermore, experiments on the targeted contamination and regeneration of ionomer membranes with metal ions were carried out (Fig. 5). The generated data were used by the partner FUMATECH to optimize the ionomer membranes.

Project information

Project title

MegaLyseurPlus – Development, design and construction of a modular, innovative and cost-efficient PEM electrolysis system of 1.25 MW with downstream compression plant

Subproject

Investigations on membranes and membrane electrode units

Project duration

November 2019 – May 2022

Project partners

- Fraunhofer Institute for Microstructure of Materials and Systems IMWS (Coordinator)

- Fraunhofer Center for Chemical-Biotechnological Processes CBP

- FUMATECH BWT GmbH

- Infineon Technologies AG

- Infineon Technologies Bipolar GmbH & Co. KG

- Siemens AG

- BORSIG ZM Compression GmbH

- Hannweber Engineering GmbH

Funding

We would like to thank the German Federal Ministry of Education and Research (BMBF) for funding the project »MegaLyseurPlus«, grant number 03ZZ0752H.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB