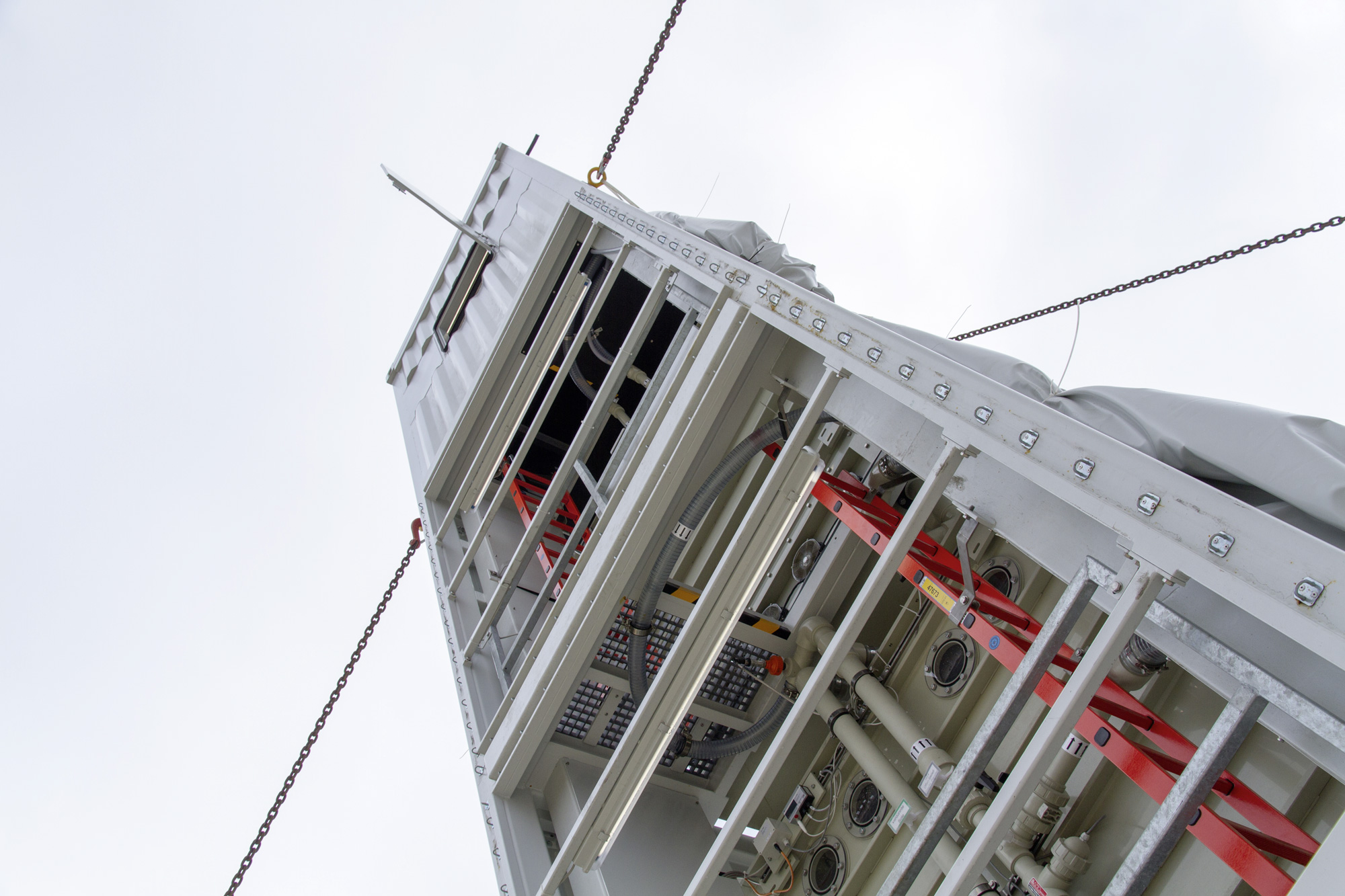

Water vapor in the atmosphere is a source of high-quality drinking or process water. Current research at Fraunhofer IGB is focusing on the use of efficient adsorption systems that capture atmospheric water and, when required, release this as drinking water and other purposes.

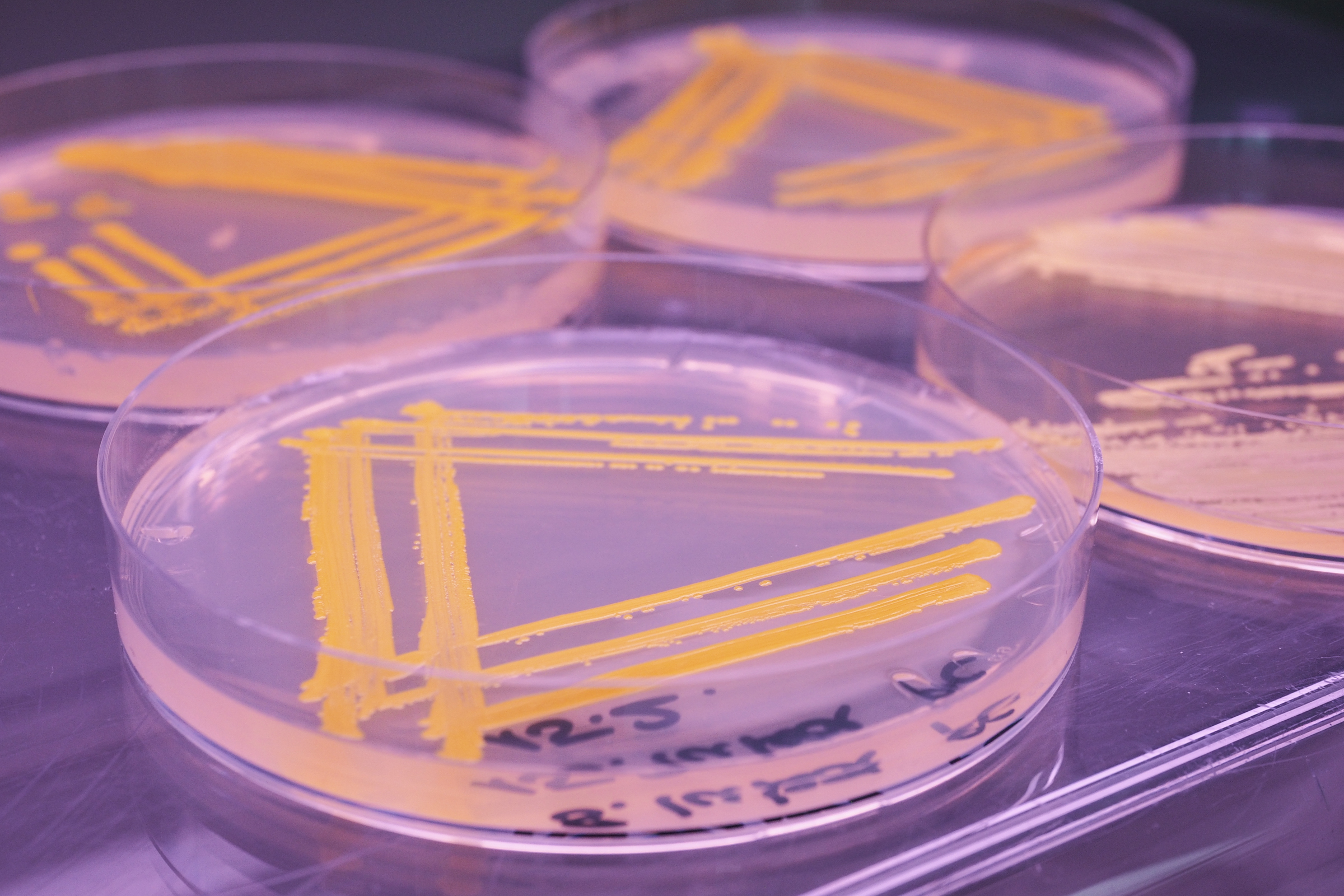

We have many years of expertise in the investigation of bacterial contamination and in the determination of the efficacy of individual disinfection approaches. We specialize in the identification of bacteria, viruses and fungi as well as in the analysis of biofilms and how to reduce or avoid them in technical systems.

Further developments focus on the removal of micropollutants by means of advanced oxidation processes (AOP) and membrane adsorbers.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB