Further publications to consider

V. Kumar, D. Avisar, V.L. Prasanna, Y. Betzalel, H. Mamane (2020): Rapid visible-light degradation of EE2 and its estrogenicity in hospital wastewater by crystalline promoted g-C3N4, Journal of Hazardous Materials, p.122880.

I. Horovitz, V. Gitis, D. Avisar, H. Mamane (2020): Ceramic-based photocatalytic membrane reactors for water treatment–where to next?, Reviews in Chemical Engineering. https://doi.org/10.1515/revce-2018-0036.

T. Peng, J. Pulpytel, I. Horovitz, A.K. Jaiswal, D. Avisar, H. Mamane, J.A. Lalman, F. Arefi-Khonsari (2019): One‐step deposition of nano‐Ag‐TiO2 coatings by atmospheric pressure plasma jet for water treatment: Application to trace pharmaceutical removal using solar photocatalysis, Plasma Processes and Polymers, 16 (6), 1800213.

I. Horovitz, D. Avisar, E. Luster, L. Lozzi, T. Luxbacher, H. Mamane (2018): MS2 bacteriophage inactivation using a N-doped TiO2-coated photocatalytic membrane reactor: Influence of water-quality parameters, Chemical Engineering Journal, 354, 995-1006.

A. Dandapat, I. Horovitz, H. Gnayem, Y. Sasson, D. Avisar, T. Luxbacher, H. Mamane (2018): Solar Photocatalytic Degradation of Trace Organic Pollutants in Water by Bi (0)-Doped Bismuth Oxyhalide Thin Films, ACS omega, 3(9), 10858-10865.

E. Luster, D. Avisar, I. Horovitz, L. Lozzi, M.A. Baker, R. Grilli, H. Mamane (2017): N-Doped TiO2-Coated Ceramic Membrane for Carbamazepine Degradation in Different Water Qualities, Nanomaterials, 31, 7(8). E206. doi: 10.3390/nano7080206.

I. Horovitz, D. Avisar, R. Grilli, A.D. Enevoldsen, D. Di Camillo, M.A. Baker, L. Lozzi, H. Mamane (2016): Carbamazepine degradation using a N-doped TiO2 coated photocatalytic membrane reactor: influence of physical parameters, Journal of Hazardous Materials, 310, 98–107.

N. Meorn, V. Blass, Y. Garb, Y. Kahane, G. Thoma (2016): Why Going beyond Standard LCI Databases is Important: Lessons From A Meta-Analysis of Potable Water Supply System LCAs, International Journal of Life Cycle Assessment, 21(8); 1134–1147.

N. Meorn, V. Blass, G. Thoma (2020): Selection of the Most Appropriate Life-cycle Inventory Dataset: New Selection Proxy Methodology and Case Study Application, Journal of Life Cycle Assessment 25: 771–783.

N. Meorn, V. Blass, G. Thoma (2020): A National Level LCA of a Water Supply System in a Mediterranean-Semi-Arid Climate – Israel as a Case Study, International Journal of Life Cycle Assessment 25: 1133–1144.

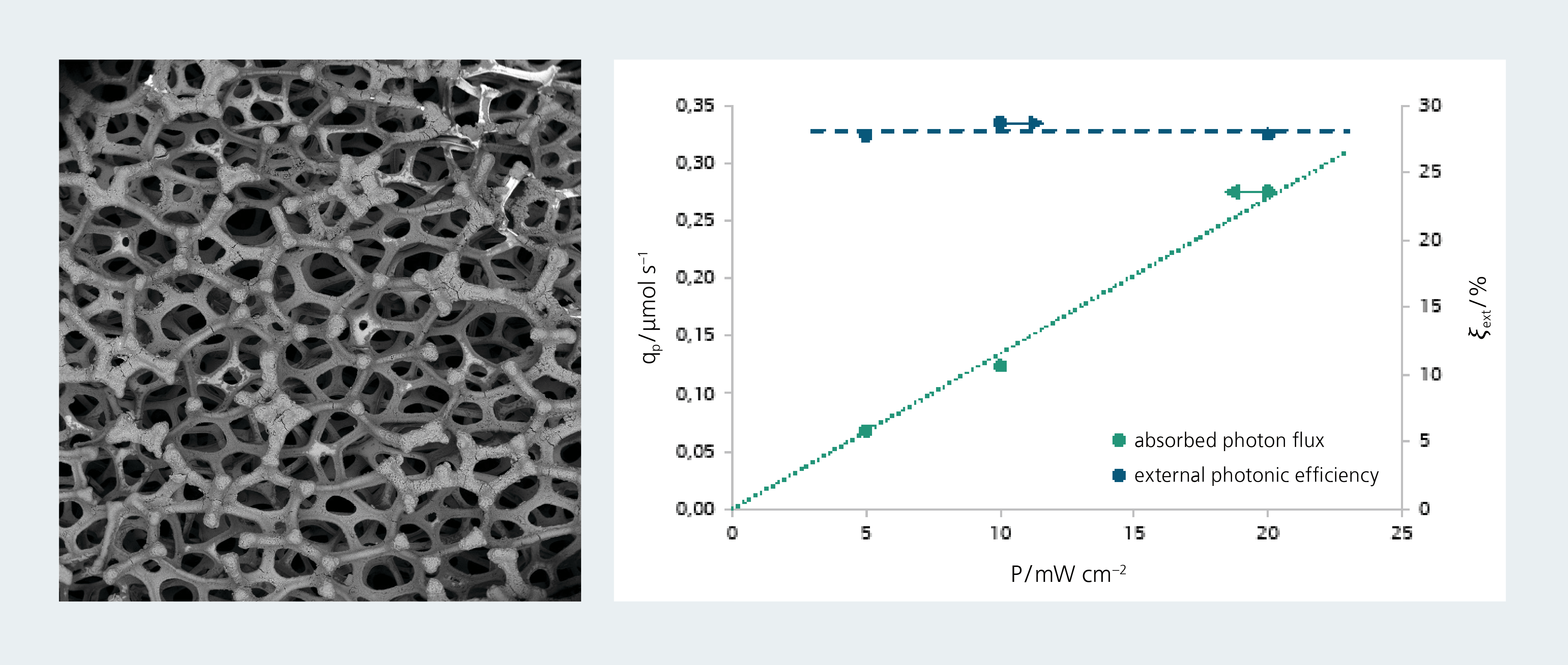

I. Reim, B. Wriedt, Ü. Tastan, D. Ziegenbalg, M. Karnahl (2018): Impact of the Type of Reactor and the Catalytic Conditions on the Photocatalytic Production of Hydrogen Using a Fully Noble‐Metal‐Free System, ChemistrySelect 3, 2905–2911.

S. Triemer, M. Schulze, B. Wriedt, R. Schenkendorf, D. Ziegenbalg, U. Krewer, A. Seidel-Morgenstern (2021): Kinetic analysis of the partial synthesis of artemisinin: Photooxygenation to the intermediate hydroperoxide, Journal of Flow Chemistry 11, 641–659.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB