Novel biodegradable bone replacement materials for regenerative medicine

Initial situation

In our ageing society, an increasing number of patients suffer from skeletal defects caused by injuries, cancer or other bone diseases. Thus, there is great interest in developing novel three-dimensional bone replacement materials. The challenge is to develop new, forward-looking paths for the fabrication of clinically usable carrier materials and implants.

Material development

The use of additive fabrication methods for three-dimensional implants that are very similar to the natural bone structure has great potential for personalized medicine. Although it is nowadays possible to reproduce the complex structure of natural bones using additive methods, to date it has not been possible to induce an improved adhesion of bone cells with any material (neither with metal nor with polymer materials). The most promising approach is the use of improved coating techniques and composite materials.

New hybrid scaffolds with controlled porous hierarchy

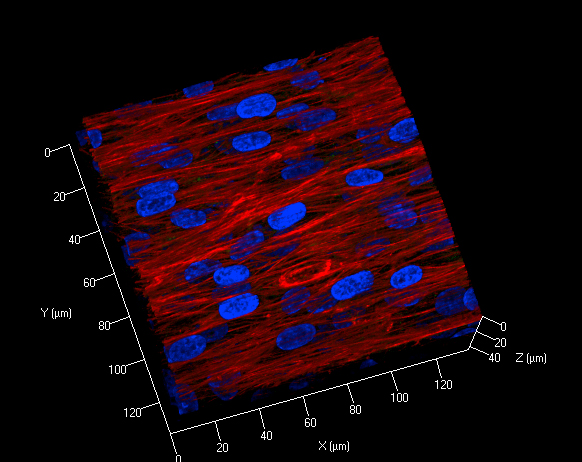

The international BMBF-funded Intelbiocomp project developed a novel 3D polymer bone replacement material on the basis of polycaprolactone (PCL) that will accelerate integration into bone. This type of carrier material with different orientation of the polycaprolactone fibers was fabricated at the Polytechnic University in Tomsk, Russia. The different orientation of the fibers is both helpful for the reproduction of extracellular matrix and, moreover, additional modification of the surface with silicon hydroxylapatite will improve bioactivity and bone growth of the novel hybrid material.

Biological validation of the newly developed materials

Cell vitality is of great importance for the clinical use of bone replacement materials. It is therefore important to investigate bioactivity of the newly developed hybrid material. The cell adhesive and osteoinductive properties of these materials were analyzed in human mesenchymal stem cells (hMSC) at Fraunhofer IGB. The Cell and Tissue Engineering department has many years of experience in the development of these test procedures. We demonstrated that adhesion and proliferation could be improved significantly using the novel design of the hybrid material.

Outlook

One result of the project is to combine methods from the basic research of biomaterial development in the field of customized implants with the needs of the industry. With the new fabrication methods, fabrication time and costs for individual bone replacement can be significantly reduced and gaps in implant fabrication can be filled. Because the implants can be tailored precisely to the individual medical situation, there are very good opportunities for a successful market launch. Collaboration with Russia creates particularly promising opportunities, since this extends the economic territory beyond the European market. Upon completion of the project, the cell-based test methods to determine cell adhesion and osteoinduction developed in the framework of the overall project are now available for testing with different bone replacement materials at Fraunhofer IGB.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB