Pilot plant for a mild EthaNa process

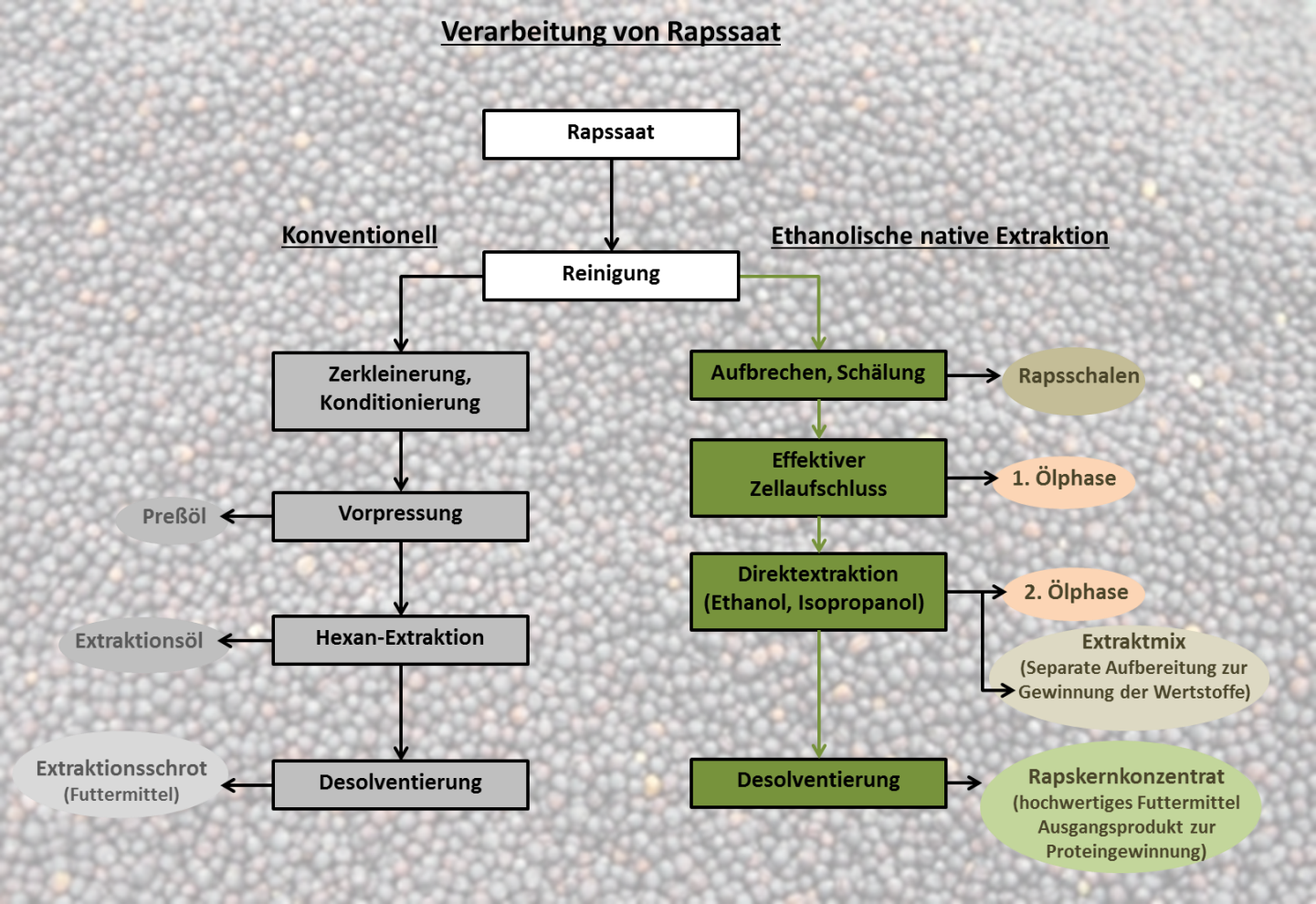

The mild EthaNa process represents an alternative approach. It is performed at ambient pressure and temperatures of no more than 70°C, uses ethanol instead of hexane or petroleum-based solvents and is capable of processing de-hulled rapeseed. On completion of the project, in 2022, a pilot plant – consisting of a de-hulling system and an extraction system – was built and put into operation at Fraunhofer CBP in Leuna.

EthaNa: improved oil quality, valuable by-products

The research has revealed that the oil is displaced from the kernel during the EthaNa process rather than being extracted in the usual manner. Consequently, the rapeseed oil obtained in this way is of higher quality than oil produced using conventional methods. In addition, the rapeseed concentrate is rich in nutritious proteins and contains significantly fewer hulls. The hull fraction is an additional product that can, for instance, be used to manufacture insulating materials. Moreover, valuable molecules such as sinapinic acid or phospholipids dissolve in ethanol and can be used in the cosmetic or pharmaceutical industries. Strategies for separating and processing these molecules are subject of current research work.

Rapeseed concentrate with native proteins

The mild conditions of the EthaNa process lead to a rapeseed concentrate that is rich in high-quality, non-denatured proteins. Together with our partners, we are researching how this can be utilized as a source of protein for food production as part of the Like-a-Pro project that has recently been launched with the sponsorship of the EU.

In the course of the project, the EthaNa® plant is further optimized in terms of oil separation, the size of the rapeseeds is correlated with the quantity of oil released and a countercurrent process is established for ethanol extraction.

In addition, efforts are being made to establish new cooperations for expanding the range of raw materials that can be processed with the EthaNa® plant. Some promising candidates in this regard are sunflower seeds, beechnuts or residual products such as coffee grounds or hemp seeds.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB