The lighthouse project “E3-production” addresses these three pillars and focuses, notably, on the design and implementation of ultra-short process chains, the operation of production systems that can adapt their use of energy and resources to a volatile energy supply, the establishing of closed-loop material cycles, and the use of production itself to store energy, including the integration of materials. With regard to the reduction of emissions, approaches being examined include completely closed-loop energy and material re-use cycles, and also the recovery of energy, culminating in self-regulated recycling. The project involves the collaboration of the Fraunhofer Institutes FIT, IBP, ICT, IFF, ILT, IML, IPA, IPK, IPT, IWU, UMSICHT and IGB.

IGB's contribution: Ultra-short process chains and sustainability analysis

Fraunhofer IGB is involved in two subprojects.

In the first, our contribution is the demonstration of ultra-short production processes used in biotechnology and process engineering, as shown by the example of a reactor concept for the bioprecipitation of metals. The concept has the aim of facilitating integration of the bioprecipitation process into existing process chains, while at the same time taking the required product quality into account. Featuring internal recycling and loop closure, it will thus contribute to overall resource efficiency.

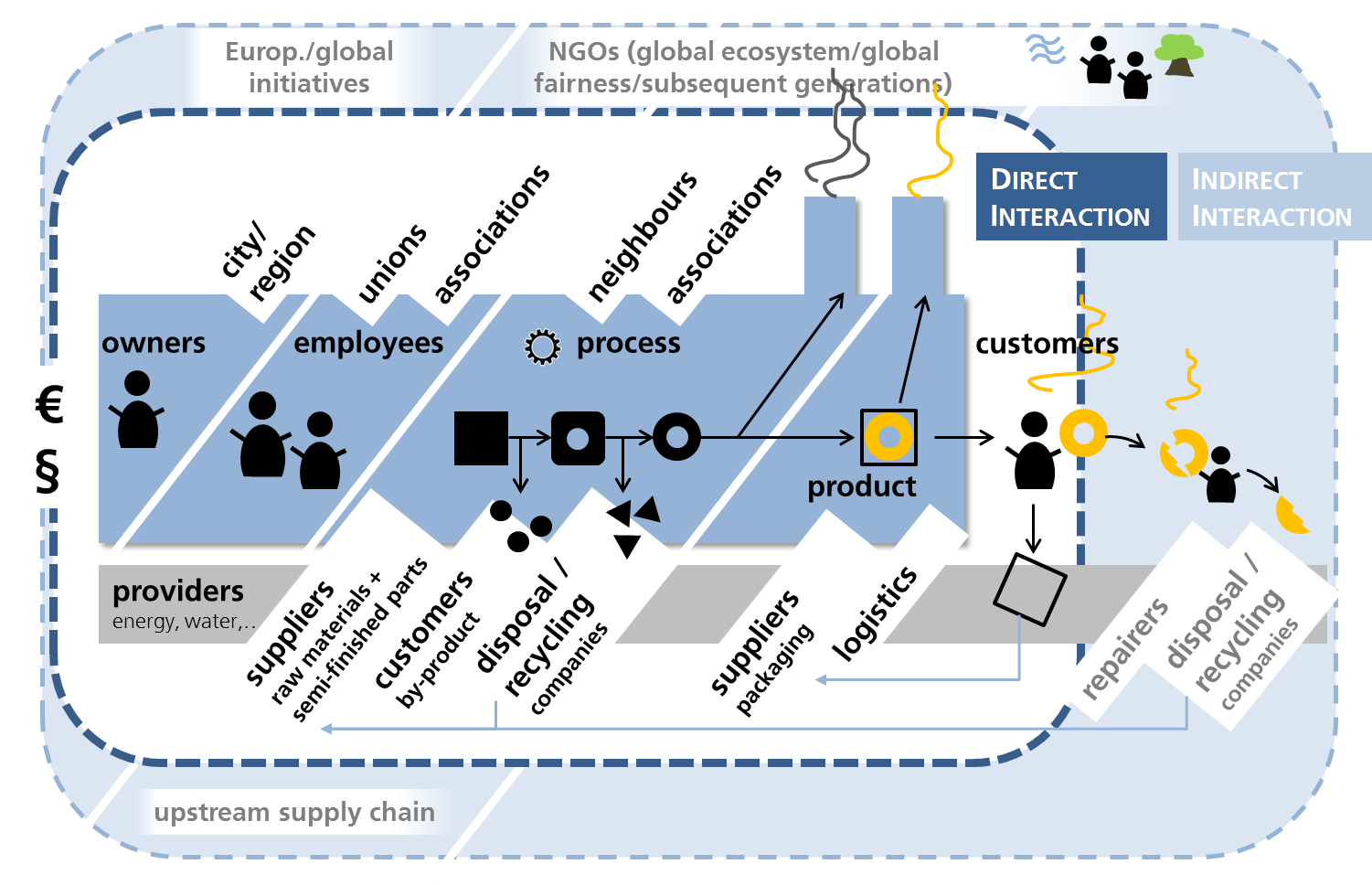

In the subproject SUSPROFIT a practical, industry-specific evaluation system is being developed that identifies the sustainability risks and indicates options for action.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB