Insects as protein source: Need for pathogen detection

However, the production of insects on an industrial scale also promotes the spread of diseases, which can lead to the collapse of insect breeding, production losses and thus serious financial losses. In addition, the insect-based food must be free of human and animal pathogens. A specific and efficient detection system for pathogens in insect farms that is automated, digitized and capable of high-throughput, and that can deliver results promptly and on site, is still missing.

Currently, classic, culture-dependent methods or metagenomic approaches are applied to identify microorganisms in the gut and in the breeding tanks of insects. Both approaches are expensive, time-consuming and tedious, and thus not suitable for daily routine inspections in insect farms.

DNA-based detection of insect pathogens

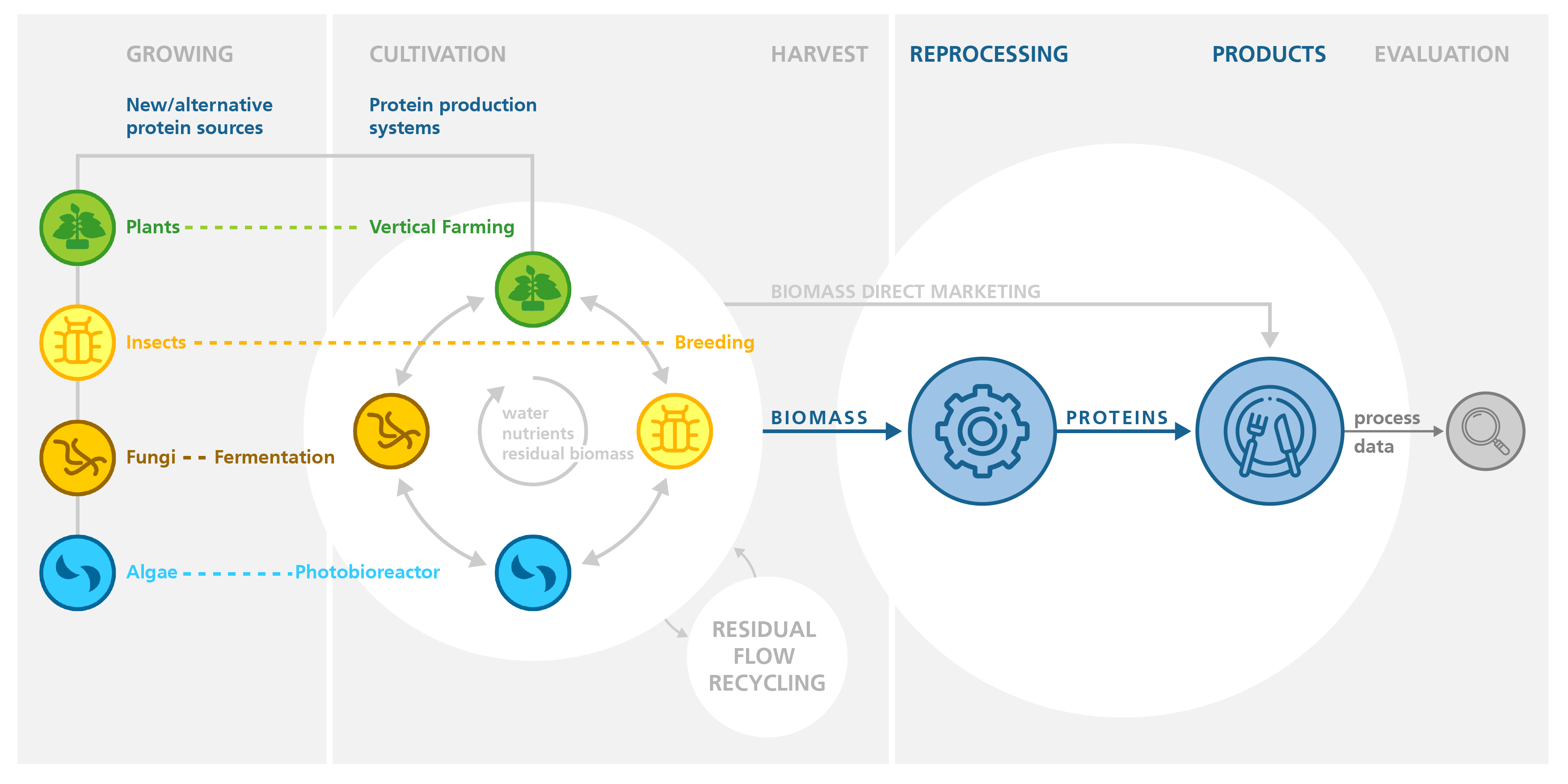

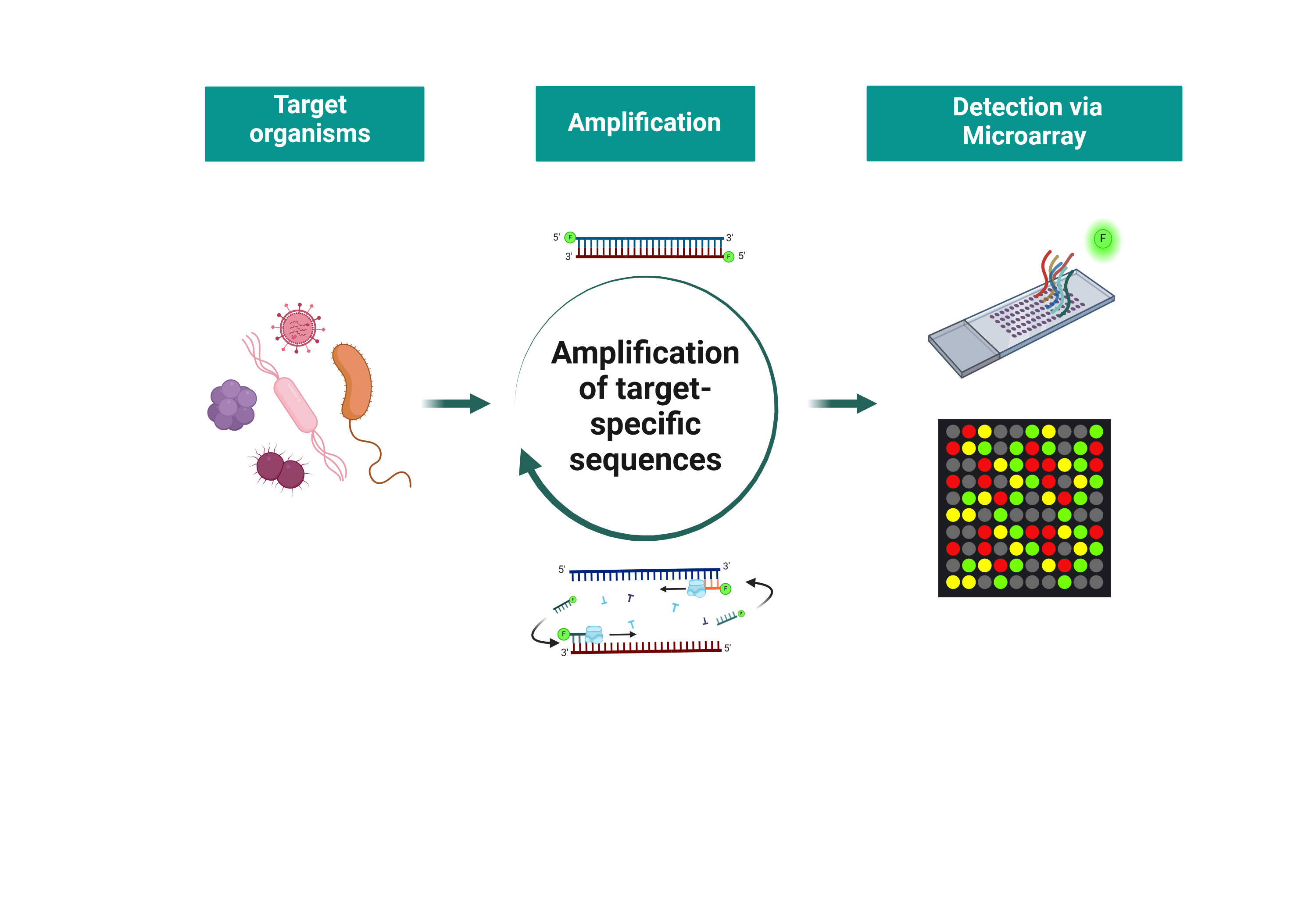

As part of the FutureProteins lighthouse project, the IGB is developing an automated monitoring system for insect farming together with the Fraunhofer institutes IME and IVV: For this purpose, a molecular detection system covering the eleven most important insect-associated pathogens is being developed at the IGB.

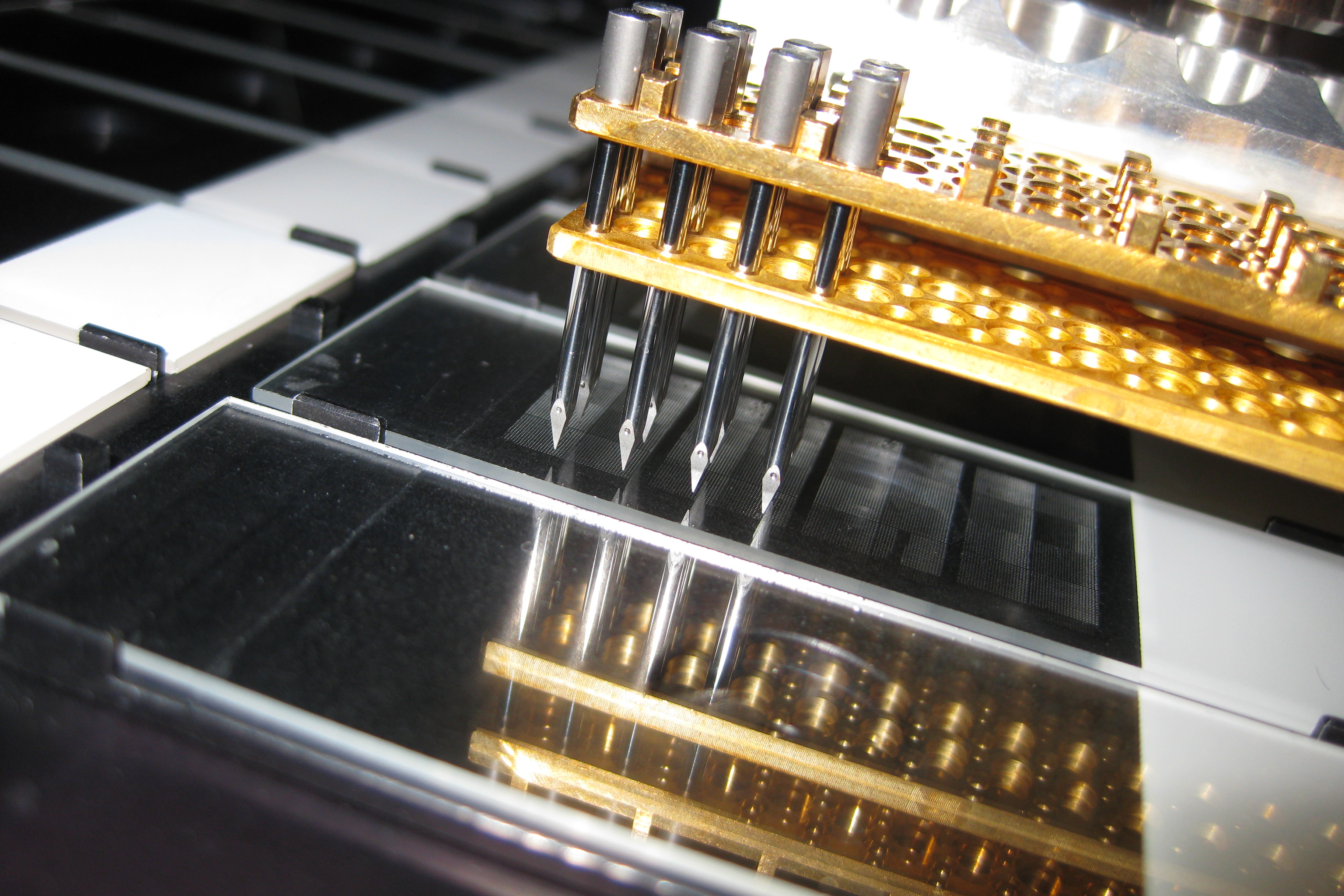

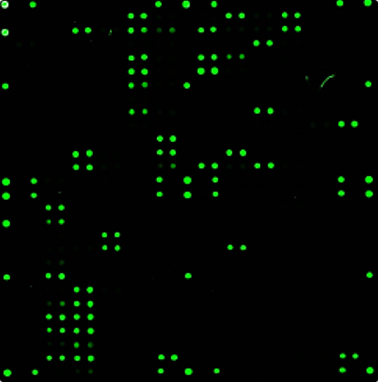

Using insect sample material, DNA signatures of the pathogens are amplified and fluorescently labeled using an isothermal amplification technique. Specific binding to an immobilized probe results in a fluorescent signal that is identified optically and evaluated using a simple matrix. This technique allows for much easier handling than the commonly used PCR applications. In the future, the detection system developed for routine inspection at production sites will be integrated into a partially or fully automated inline system and can ultimately help to minimize the use of antibiotics and promote the resource-saving production of proteins.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB