Sub-project: Electrochemical generation of ethylene

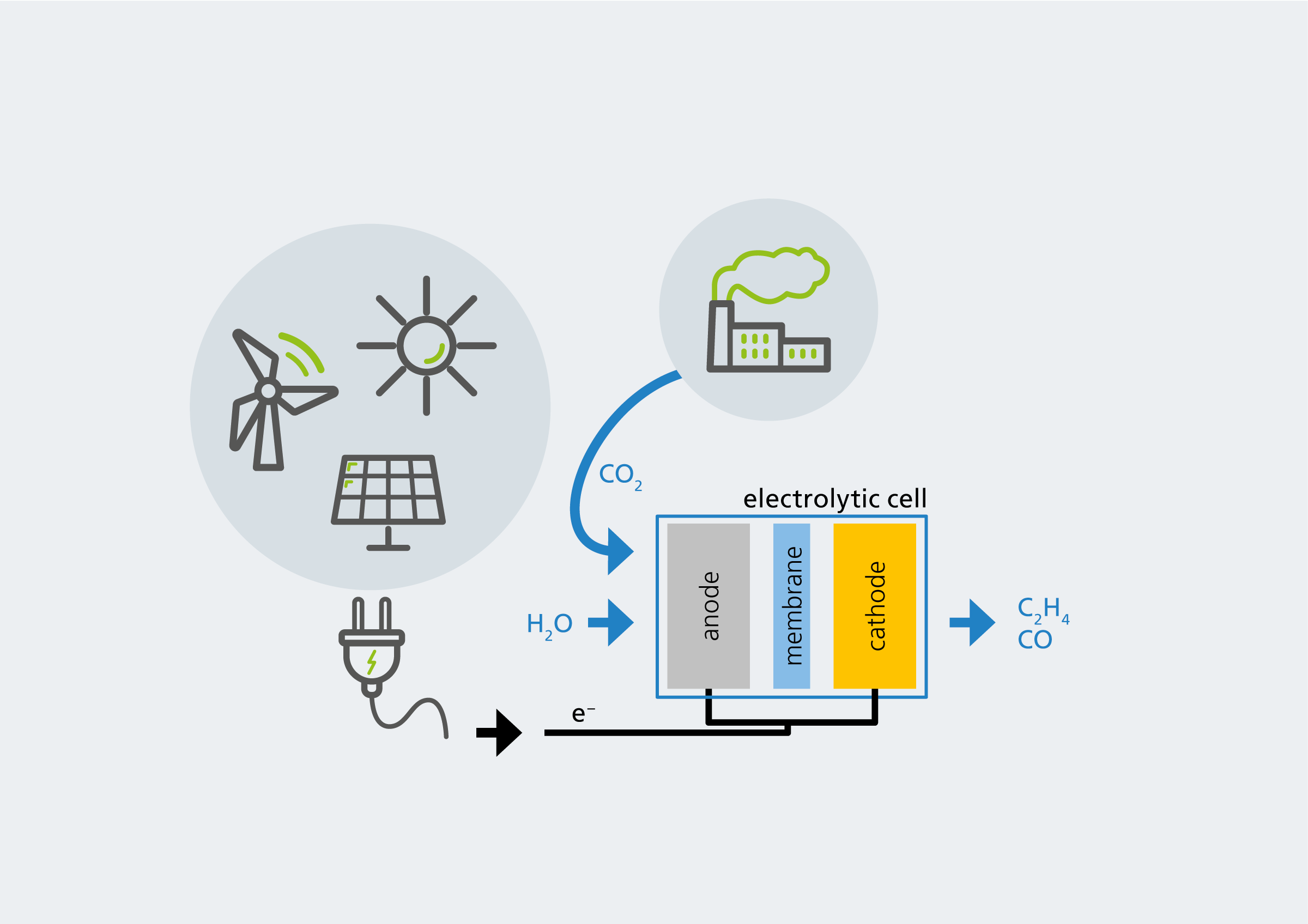

Fraunhofer IGB is coordinating the sub-project entitled “Development of a new one-step electrochemical process with which alkenes, mainly ethylene, will be electrochemically produced from CO2 and water". The primary innovation in this sub-project consists of producing ethylene or other alkenes through direct reduction of CO2 in just a one-step process. The goalpost for the process is to demonstrate ethylene production on a scale of one kilogram per day.

A total of four departments at Fraunhofer IGB are working together on this project. The BioCat group in Straubing is looking after the development of the catalysts, optimizing reaction of the electrodes, and characterizing the materials. The research focus of the Department of Interfacial Engineering and Materials Science is developing and characterizing charge-carrying materials (membranes and gas diffusion electrodes) as well as characterizing and optimizing interface phenomena at triple-point phase changes. The Department of Physical Process Technology is looking after the electrode configuration, system integration and setup, and the testing and optimizing of the pilot plant. The necessary measurement, monitoring, and control engineering is being contributed by the Department of Environmental Biotechnology and Bioprocess Engineering.

The development is being carried out in close cooperation with the parallel work packages for process simulation (Fraunhofer ITWM) and component development & process analysis (ISC, IST and IAP).

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB