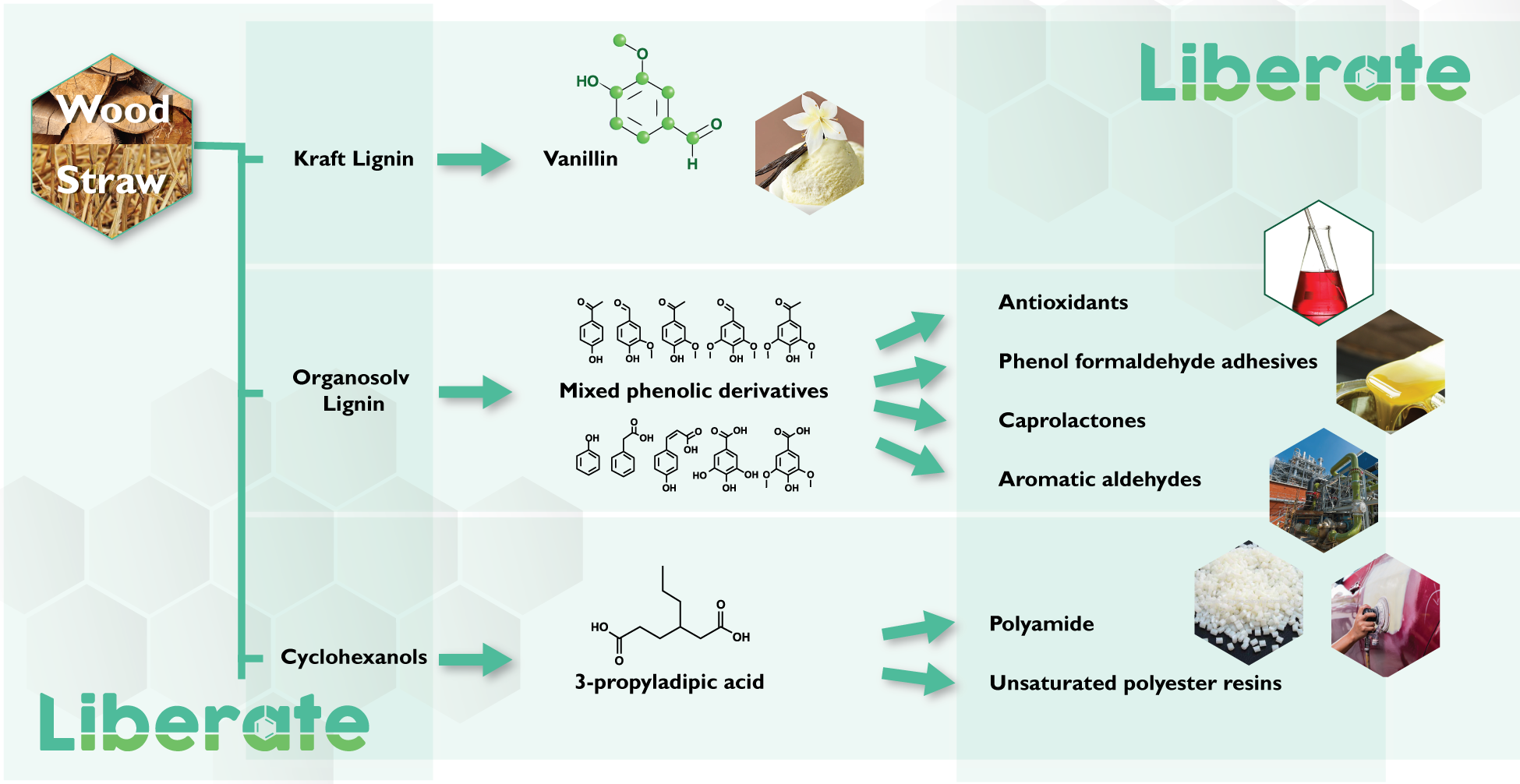

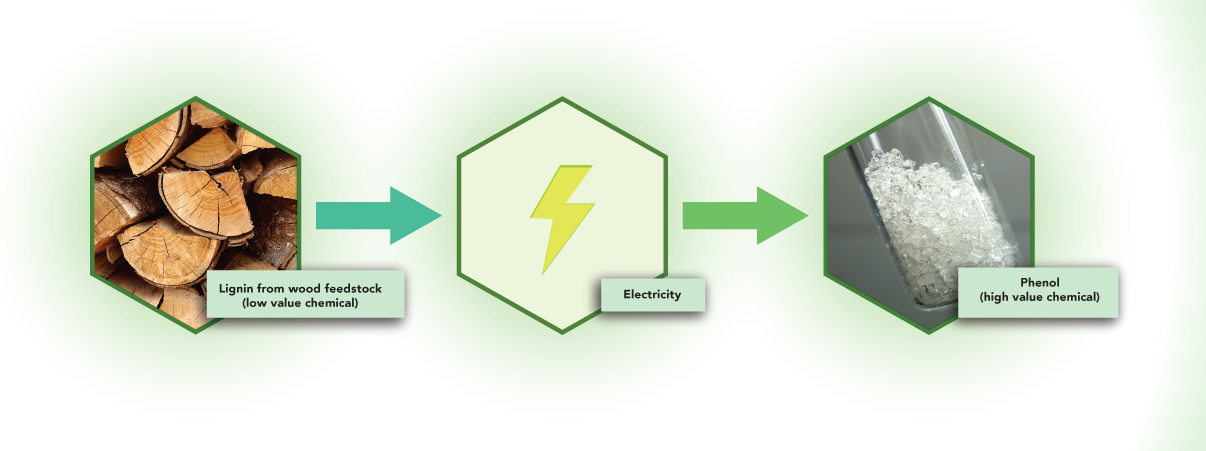

The aim of the LIBERATE collaborative project funded by the EU is to convert low-cost lignin feedstock into high-value and biosustainable chemicals such as vanillin or building blocks for biopolymers by electrochemical processes. For this, LIBERATE will deliver a pilot scale electrochemical plant and demonstrate a process for energy efficient conversion of lignin.

LIBERATE – Lignin Biorefinery Approach using Electrochemical Flow

LIBERATE – Lignin Biorefinery Approach using Electrochemical Flow

With a grant of 10 million euros from European Union’s Horizon 2020 Framework Programme for Research and Innovation, the LIBERATE collaborative project started in October 2018. The idea of the project carried out by an international consortium is to convert low-cost lignin feedstock from wood into high-value and biosustainable chemicals by means of an electrochemical process. For this, LIBERATE will deliver a pilot scale electrochemical plant to demonstrate the conversion of lignin into chemicals such as vanillin and building blocks for biobased polymers, currently coming from the petrochemical industry.

By developing and demonstrating the electrochemical lignin biorefinery, LIBERATE will help Europe to go a further step towards a circular economy model – making the industry less dependent from imported oil and reducing the impact of industries on the environment by reducing CO2 emissions and increase energy efficiency.

The organosolv lignin used in the project is fractionated in the "lignocellulose biorefinery" at Fraunhofer CBP and provided in the required qualities. Highly efficient and selective anodic electrochemical oxidation will be applied to the depolymerisation of lignin to deliver a range of biosustainable chemicals for drop in replacements or for superior product performance. For this, the Straubing-based BioCat branch is developing a process for oxidative lignin degradation with the aim of producing phenols.

Objectives

- Electrochemical depolymerisation of kraft lignin to synthesise vanillin with a 7 percent yield.

- Electrochemical depolymerisation of organosolv lignin to synthesise mixed phenolic derivate oligomers with a yield of > 35 percent.

- Electrochemical oxidation of biosustainable cyclohexanol to synthesise propyl adipic acid with a yield of up to 80 percent.

- A biorefinery process

- capable of accommodating renewable energy fluctuations without loss in efficiency.

- exhibiting a 95 percent improvement in the energy efficiency of the process and 350 percent improvement in resource efficiency.

- producing 29 times less CO2 than the conventional petrochemical alternatives.

Project information

Project title

LIBERATE – Lignin Biorefinery Approach using Electrochemical Flow

Project duration

October 2018 – September 2022

Project partners

Research Partners

- LEITAT, Spain (Coordination)

- Fraunhofer IGB with its branches BioCat, Straubing, and Fraunhofer CBP, Leuna

- ECN Part of TNO, Netherlands

- SINTEF AS, Norway

- Johannes Gutenberg University Mainz, Germany

- University of Alicante, Spain

SMEs and large enterprises

- Chimar Hellas AE, Greece

- Condias GmbH, Germany

- Enso Innovation S.L., Spain

- Evonik Resource Efficiency GmbH, Germany

- Gate2Growth APS, Denmark

- Optimización Orientada a la Sostenibilidad S.L. (Idener), Spain

- Megara, Greece

- NX Filtration BV, Netherlands

- Perstorp AB, Sweden

- Oxiris Chemicals S.A., Spain

Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement no 820735.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB