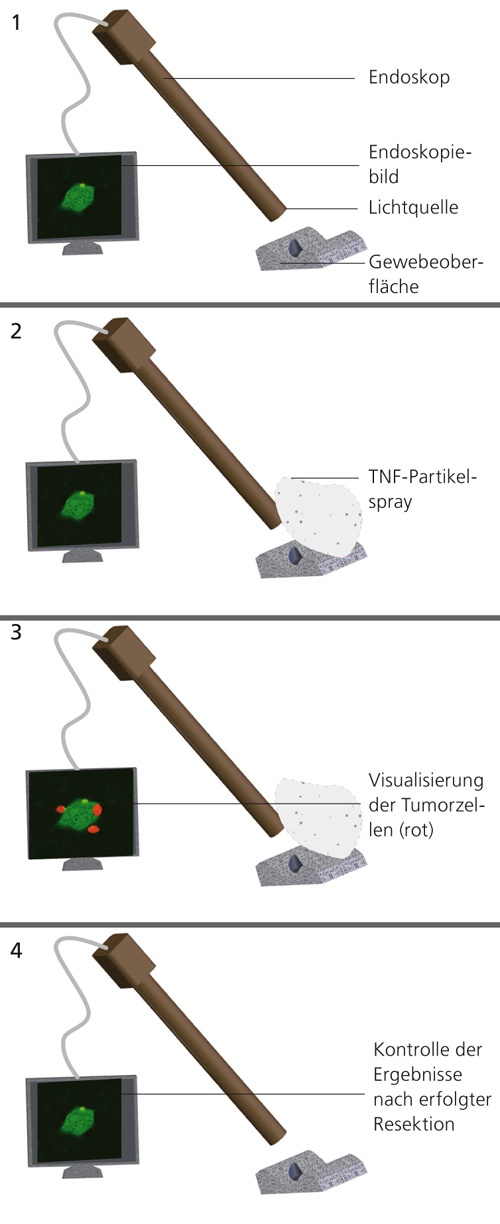

During the course of minimally invasive tumor resection, it is often difficult for the surgeon to clearly distinguish between healthy and sick tissue on the endoscopic image. Furthermore, the surgeon does not perceive the haptic and tactile sensations needed to evaluate the tissue by means of palpation. The use of navigation systems to localize the tumor usually fails due to the presence, quality, accuracy or the informational content of the image data. Therefore, a tumor sample is usually taken during surgery and given to the pathologist. This procedure can take up to one-half hour and requires that the operation be “put on hold” for this period of time. However, a final laboratory examination can take significantly longer. To minimize the risk, the surgeon supplements the expertise of the pathologist and a mutual assessment of the tissue status is usually made. This decision is extremely risky, for example, if the partial resection of a tissue or an entire organ depends on it. Quality control of the resection margins is so far not possible by any means. Thus, the necessity of resecting large volumes remains for reasons of safety. Project C-VIS concerns an alternative method which in a short period of time can directly help visualize the tumor tissue in the body.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB