Continuous finishing of foils and web material

The many issues for which Fraunhofer IGB develops coating processes do not stop at small laboratory systems. Thanks to our excellent facilities, we are also able to carry out scaling concepts such as the continuous treatment of fiber and roll materials (foils, nonwovens).

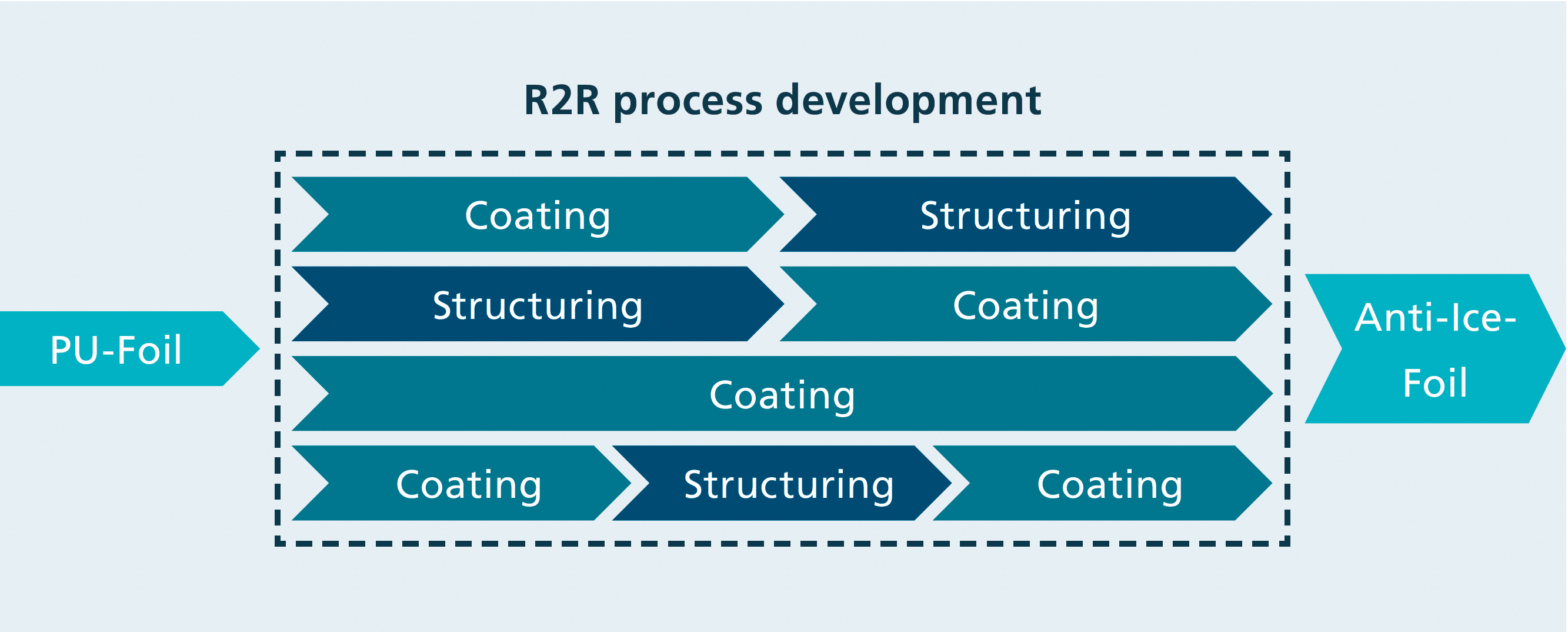

Multiple roll-to-roll process combinations

With our technical equipment, we are able to finish web materials such as films, nonwovens or textiles using wet-chemical and gas-phase processes in roll-to-roll (R2R) processes, and to combine different coating procedures.

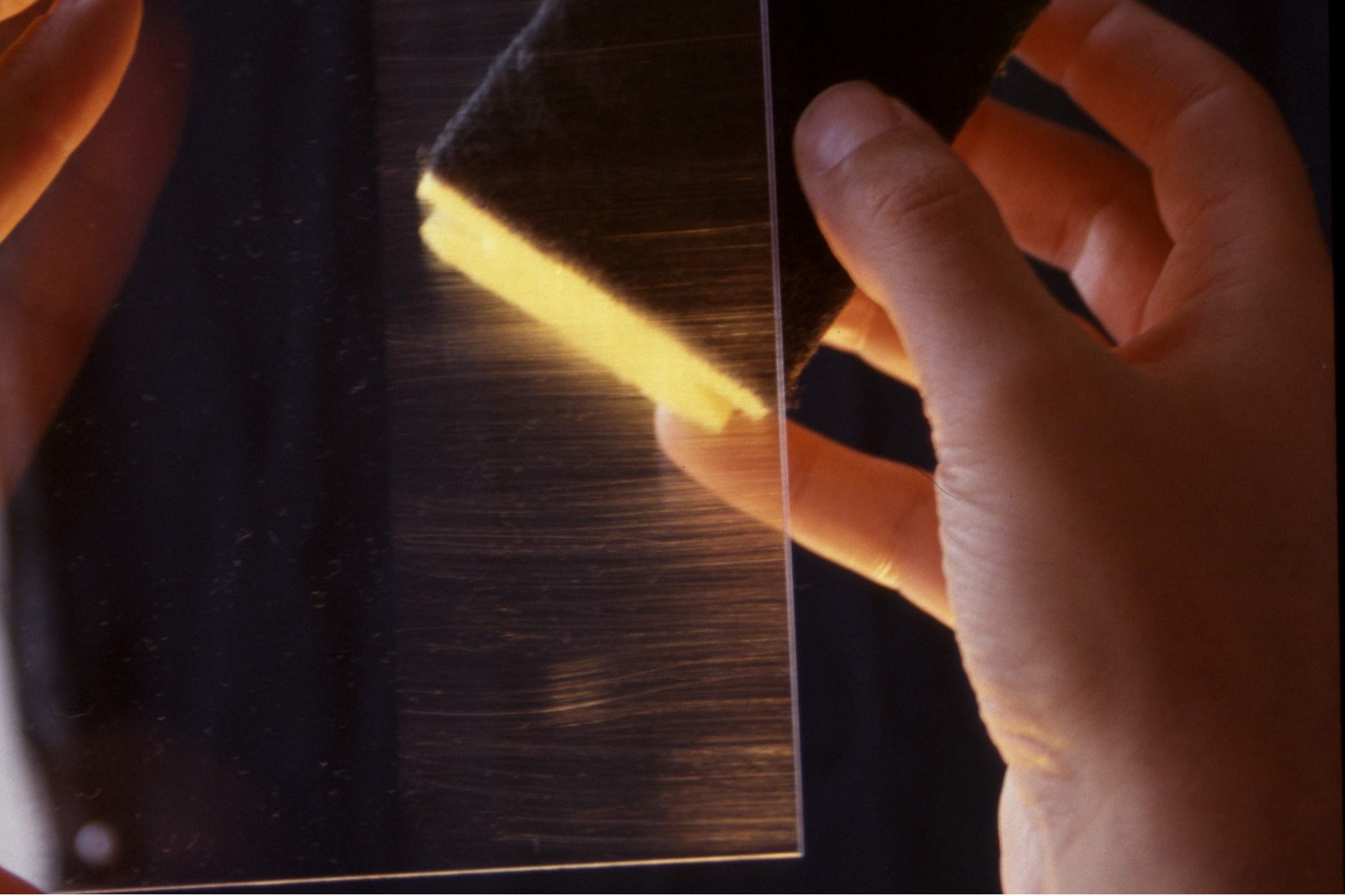

In addition, we offer processes for surface structuring, which can also be carried out in R2R. For example, films are first structured in the roll-to-roll process via hot embossing processes and then provided with ultra-thin plasma coatings to obtain superhydrophobic and ice-repellent surfaces through this combination.

Transfer of batch coating to R2R process

We develop the desired equipment and transfer the processes to an R2R process on our plants. We would be happy to discuss your project in an initial meeting, please contact us.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB