Obtaining valuable materials

Renewable resources used in the production of biofuel are increasingly gaining importance. The vegetable oils involved, for example from rape seed or soy, contain various minor components (valuable materials and contaminants). On the one hand, biodiesel contains contaminants which can negatively affect the quality of the fuel. On the other hand, smaller amounts of important valuable materials such as bioactive Vitamin E (α-tocopherol) can also be found. To date, when biodiesel is burned, these valuable materials are normally burned along with it.

Due to its antioxidant properties tocopherol plays an important role in the human body, where it protects cells from the damaging effects of oxygen. Natural tocopherol-containing extracts are separated from the seeds of oil-containing plants, especially from wheat, corn, soy, cotton and rice, and then enriched. On an industrial scale, synthetic vitamin E is produced as a racemic mixture. Since synthetic tocopherol is relatively unstable, it is normally bound to an acetyl group. Through this process it loses all antioxidant properties. Up to 50 percent of the absorbed synthetic tocopherol can, however, be converted to natural vitamin E by the body.

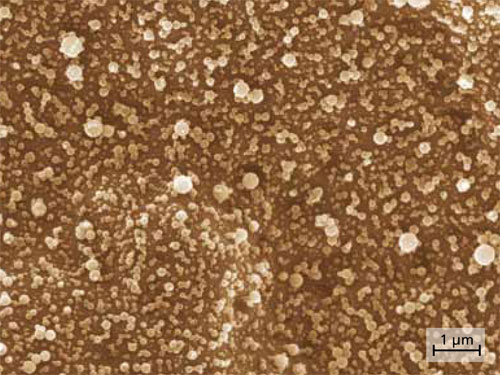

The goal of this project was to develop an adsorptive process at pilot plant scale in which valuable bioactive minor components could be extracted as additional, value-added products in plant processing. To this purpose, we included polymeric nanoscale adsorber particles in a new process concept for the separation of substances.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB