The challenge of manufacturing cell-compatible 3D objects

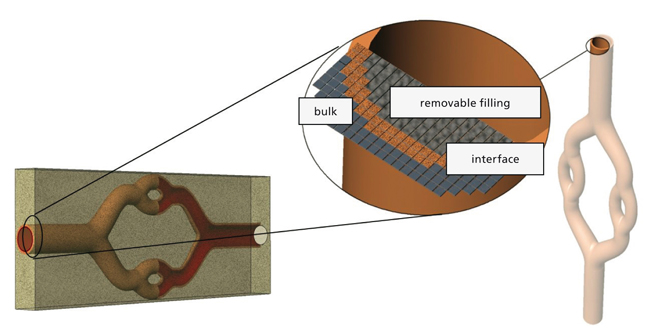

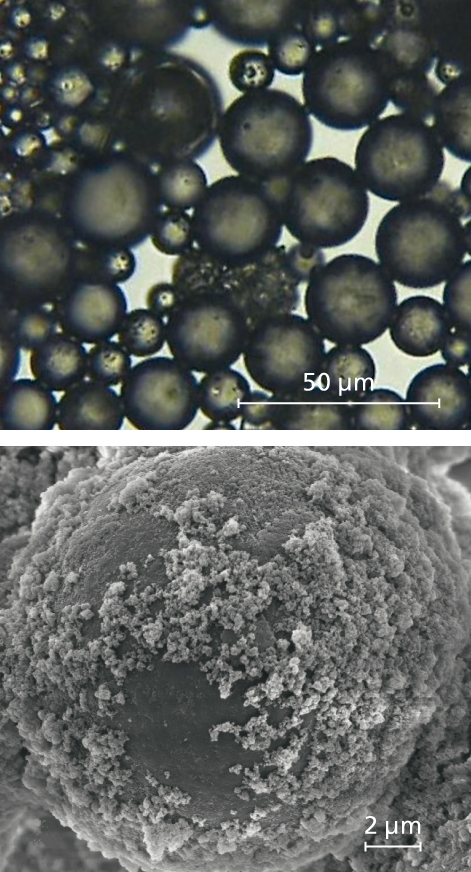

Electrophotography has developed into one of the leading digital technologies in graphic printing. The process, which is also known as xerography and laser printing, offers the possibility of arranging a variety of differently colored toner particles with high resolution and thereby individually designing a paper substrate. However, the printing process is currently largely limited to two-dimensional (2D) applications, although the large solid content of toner particles provides a good prerequisite for the fast construction of three-dimensional (3D) objects. The first commercial 3D laser printing applications are aimed at the construction of simple molded parts. The layered laser printing of cytocompatible objects like artificial arteries or other tubular structures represents a special challenge.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB