Biobased polymers from second-generation renewable resources

The raw materials for industrial biotechnology come primarily from agricultural products - glucose from sugar-containing plants such as sugar beet or starch-containing plants such as cereals, vegetable oils from seeds. However, these so-called first-generation bio-based raw materials are in competition with food production and their use for the production of biofuels or bio-based chemicals is controversial. One concept that is already being implemented in a biorefinery is the complete energetic and material use of bio-based raw materials of the so-called second generation. These include lignocellulose from wood waste or vegetable oils that are not used in the food industry.

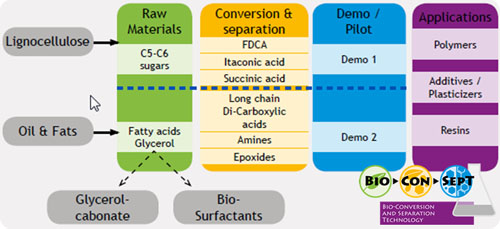

The EU-funded BioConSepT project, which involves 30 European partners from research and industry in addition to the Fraunhofer IGB, is investigating the use of second-generation raw materials for the production of biobased polymers. The aim of the project is to provide processes that convert second-generation raw materials into valuable chemicals. These processes are up to 30 percent cheaper and more sustainable than corresponding chemical or biotechnological processes that use first-generation raw materials.

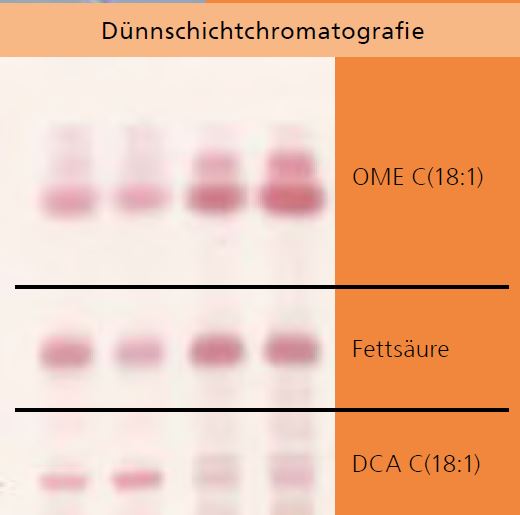

The partners have selected processes for producing chemicals from second-generation raw materials in which enzymatic, microbial and chemical reactions are used and combined. In a first selection process, 2,5-furan dicarboxylic acid, itaconic acid, succinic acid, long-chain dicarboxylic acids, diamines, diamides and epoxides were identified as target molecules. Furthermore, the production of biosurfactants and glycerol carbonate is considered. Breakthroughs in cost reduction and sustainability of the selected processes are to be achieved by introducing continuous processes, new reactors and selective separation technologies. Another goal of the project is to provide sample quantities for market testing of bio-based polymers, resins, plasticizers, biosurfactants and solvents.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB