Initial situation

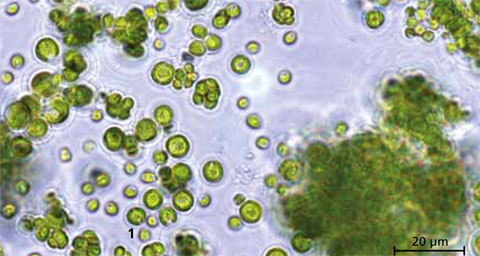

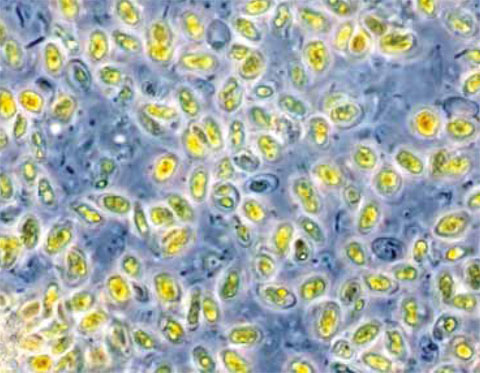

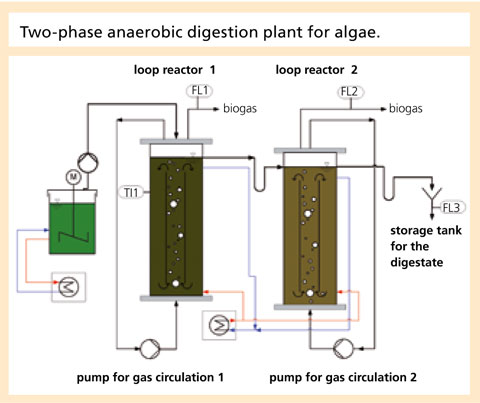

Over the next two decades, the worldwide demand for electrical energy is expected to increase by about 70 percent. Additional power plant resources are required to cover the growing demand for electricity. Moreover, the challenges of global climate protection can only be met with a sustainable energy supply. To achieve these goals, the increased and efficient use of biomass for the production of electricity and heat is indispensable. The coupling of a thermal gasifier or a biogas reactor with a microturbine is a good way to achieve this. Depending on the process, algae, wood, sludge, peat, waste, pomace and other organic residues can be used as feedstock.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB