As part of the DEUS 21 project funded by the BMBF, the Fraunhofer IGB operates a semi-central plant for anaerobic wastewater treatment with integrated membrane filtration in Knittlingen. The plant converts the organic components of the waste water and kitchen waste added via a vacuum system from about 170 residents into biogas. In the process, quantities of 8000 to 10,000 litres of biogas per day are achieved. If the building area is completely built-up, double the amount can be expected. Since this biogas has a methane content of 60-70 percent, it is a valuable source of energy whose use can reduce the need for fossil fuels.

In conventional biogas plants, biogas is produced in significantly larger quantities than in the plant in Knittlingen. Plants for the use of relatively small quantities of biogas are therefore not yet available on the market. Accordingly small plants for the use of natural gas cannot be used due to the different composition and lack of approval for biogas. The storage of biogas, which would allow utilisation with a larger aggregate, is critical for reasons of explosion protection and the location in the residential area - the biogas would have to be processed for pressure storage. For this reason, we at Fraunhofer IGB have developed an aggregate together with the Kiel-based company C-deg GmbH that enables the energetic utilisation of smaller quantities of unpurified biogas.

DEUS 21 – Storage-free utilisation of biogas

Biogas combustion with heat recovery

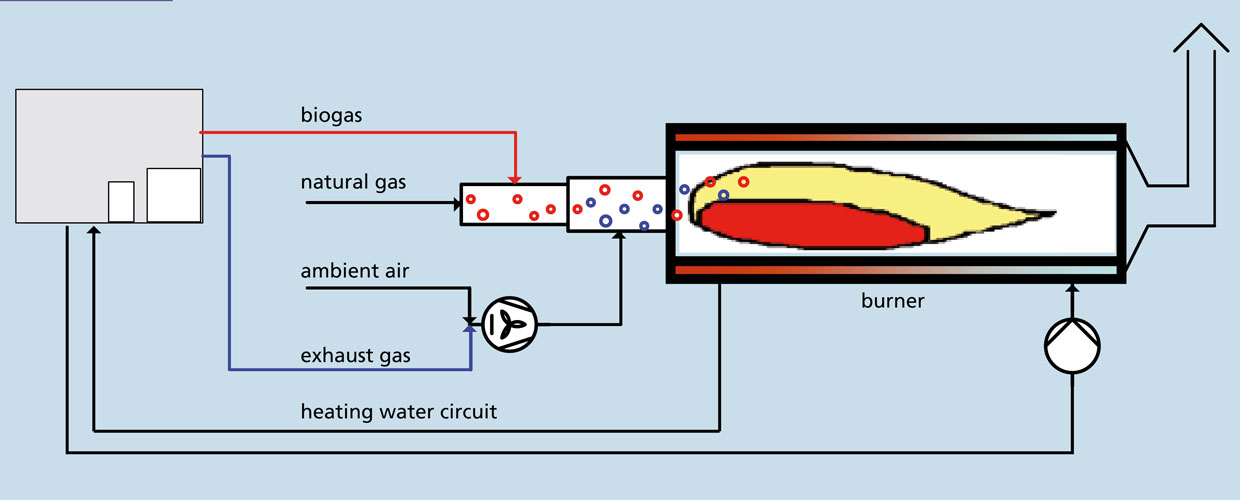

Due to the small size of the wastewater treatment plant and possible level fluctuations in the reactors, biogas is not always available, so the combustion is operated with a supporting flame that is fed with natural gas. Furthermore, an exhaust air stream from the aeration of the filtrate of the wastewater treatment plant is fed to the combustion. This air stream also contains 2-3 percent methane, which is dissolved in the filtrate and leaves the wastewater treatment plant, but must not enter the atmosphere due to the high greenhouse potential of methane. At the same time, the exhaust air transports oxygen for combustion as well as odorous substances such as hydrogen sulphide and ammonia. In order to achieve the best possible conversion of these pollutants, combustion is regulated. Thus, the supply air flow is varied according to the oxygen demand, which depends on the biogas addition. The flue gas from the combustion process is then passed through a heat exchanger in which the thermal energy of the burned gas is transferred to the heating circuit of the wastewater treatment plant. This can be used to heat the mesophilic digestion of the solids as well as the reclaim from the nitrogen recovery plant.

Advantages

The combustion of the biogas and the process air primarily results in the elimination of the greenhouse gas methane and the reduction of pollutants such as hydrogen sulphide and ammonia. However, the plant also shows that even a small amount of biogas can still be used sensibly for heat generation. Biogas can be added without pressure. The biogas is converted in the time and in the quantity in which it is produced. Pressure boosting units, gas treatment plants or gas storage tanks are therefore not necessary. The biogas plant is also not burdened by negative pressure as would otherwise be the case with active extraction of the biogas. These advantages enable a simple and cost-effective connection to a wide variety of biogas plants.

Technical data

- Regulated incineration depending on the

- Biogas feed, basic output: 6 kW

- Efficiency heat exchanger: 60-70 percent

- Combustion chamber temperature: 1000-1200 °C

Outlook

Within the presented project we were able to develop a reliable prototype, which can be further optimized in future implementations. If necessary, the technical construction of the device allows a modification of the heat exchanger. This makes it possible to use aggregates such as a Stirling engine and thus generate additional electricity. The use of heat exchangers with an increased efficiency is also possible. The heat output of the burner can be selected in the design depending on the demand. For biogas plants which continuously produce sufficient quantities of biogas, a natural gas carrier flame can be dispensed with if necessary.

Project information

Project partners

- Fraunhofer Institute for Systems and Innovation Research ISI, Karlsruhe

- Knittlingen

- Eisenmann Maschinenbau KG, Holzgerlingen (mechanical engineering)

- EnBW Energie Baden-Württemberg AG, Karlsruhe (Energy Baden-Württemberg)

- Kerafol GmbH, Eschenbach

Further information

Funding

We would like to thank the Federal Ministry of Education and Research (BMBF) for funding the project "Dezentrale Urbane Infrastruktursysteme DEUS 21" (Decentralised Urban Infrastructure Systems DEUS 21), funding code 02WD0850.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB