techtextil 2019

Insects supply chitin as a raw material for the textile industry

Fossil based chemicals are often used in textile processing. That is why the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB is researching sustainable biobased alternatives. The Institute is working on utilizing side streams from the animal feed manufacture for the production of chitosan. The biopolymer is supposed to be used as a sizing agent in the processing of yarns or for the functionalization of textiles. Fraunhofer IGB will present its work at the techtextil trade fair from May 14 – 17 in Frankfurt am Main.

Chitin is a nitrogen containing bio polysaccharide and a major component of insect skins and shells; large quantities of it result from the production of animal feed – ever since the feed industry has increasingly relied on insects as protein suppliers. Insects have the advantage that they reproduce quickly and can be bred cheaply on low-value substrates. This makes them a sustainable source of protein. Insect proteins have already been approved for poultry and pig feed. Since summer 2017, they can also be used as feeding stuff for fish. It is therefore to be expected that the use of insect proteins will become even more important in the future. Chitosan is supposed to be used as a sizing agent in the processing of yarns or for the functionalization of textiles and is produced from chitin by deacetylation. Currently, the majority of chitosan is obtained from crab shells.

Use of regionally available insect-based chitosan

The feed industry is focused on proteins, but the skins and shells of insects remain as a side product. If they can also be utilized, this contributes to the sustainability and economic efficiency of the overall feed production. The potential is enormous: in the course of their development, the larvae of the insects shed their skins several times. The remaining molting products consist up to 40 percent of chitin.

How insect chitin from animal feed production can be processed to supply biobased chemicals for textile processing, the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB and the project partners are investigating in the joint project “ChitoTex” funded by the German Ministry of Education and Research (BMBF) (promotional reference no FKZ 031A567A, BMBF).

Application of biobased chitosan as a sizing agent

The insect skins are provided by Protix (Netherlands), the leading manufacturer of insect protein. For the identification of residual material streams with a high chitin content Fraunhofer IGB developed specific analytical methods laying the foundation for the development of a suited purification processes for the polysaccharide.

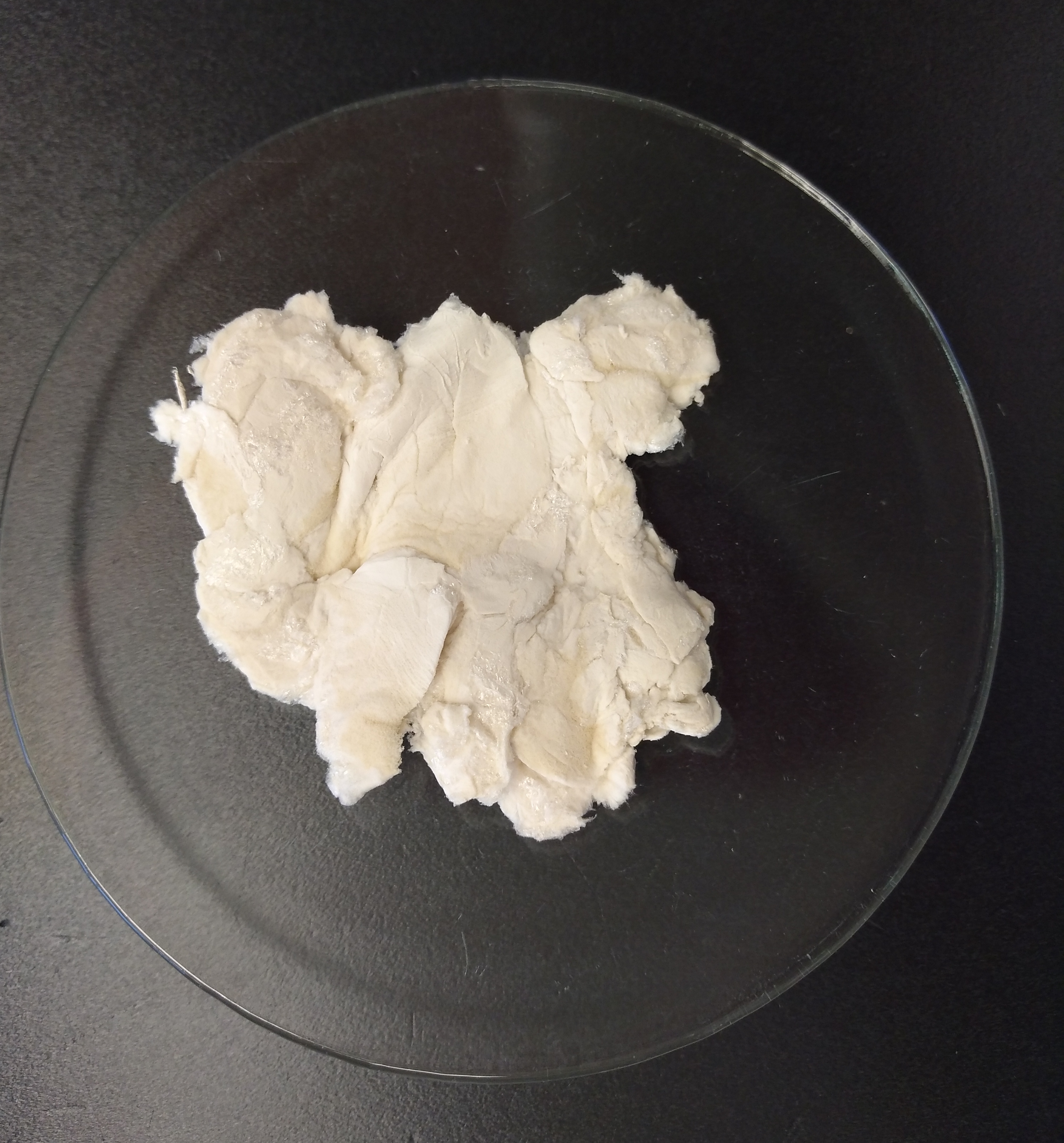

At first, the Fraunhofer researchers separate chitin from further components of the insect skins such as proteins and minerals. “We are investigating various ways of deacetylating chitin to produce chitosan,” Fraunhofer scientist Dr. Thomas Hahn explains. "Together with Eucodis (Austria) and NMBU (Norway) we have identified several suitable enzymes for the deacetylation process". The processing and subsequent conversion resulted in highly purified insect chitosan. In physico‑chemical investigations this showed similar properties to those of crab chitosan.

On the basis of application‑specific textile technology investigations at Lauffenmühle, Dr. Petry and DITF Denkendorf, the suitability of chitosan as a sizing agent was confirmed, which is also based on its ability to form films. Chitosan reduces friction in weaving machines and prevents the roughening or breaking of yarns in the weaving process; after that the sizing agent is either washed out again or remains on the yarn. In either case, biobased and natural alternatives to synthetic agents are beneficial for man and environment.

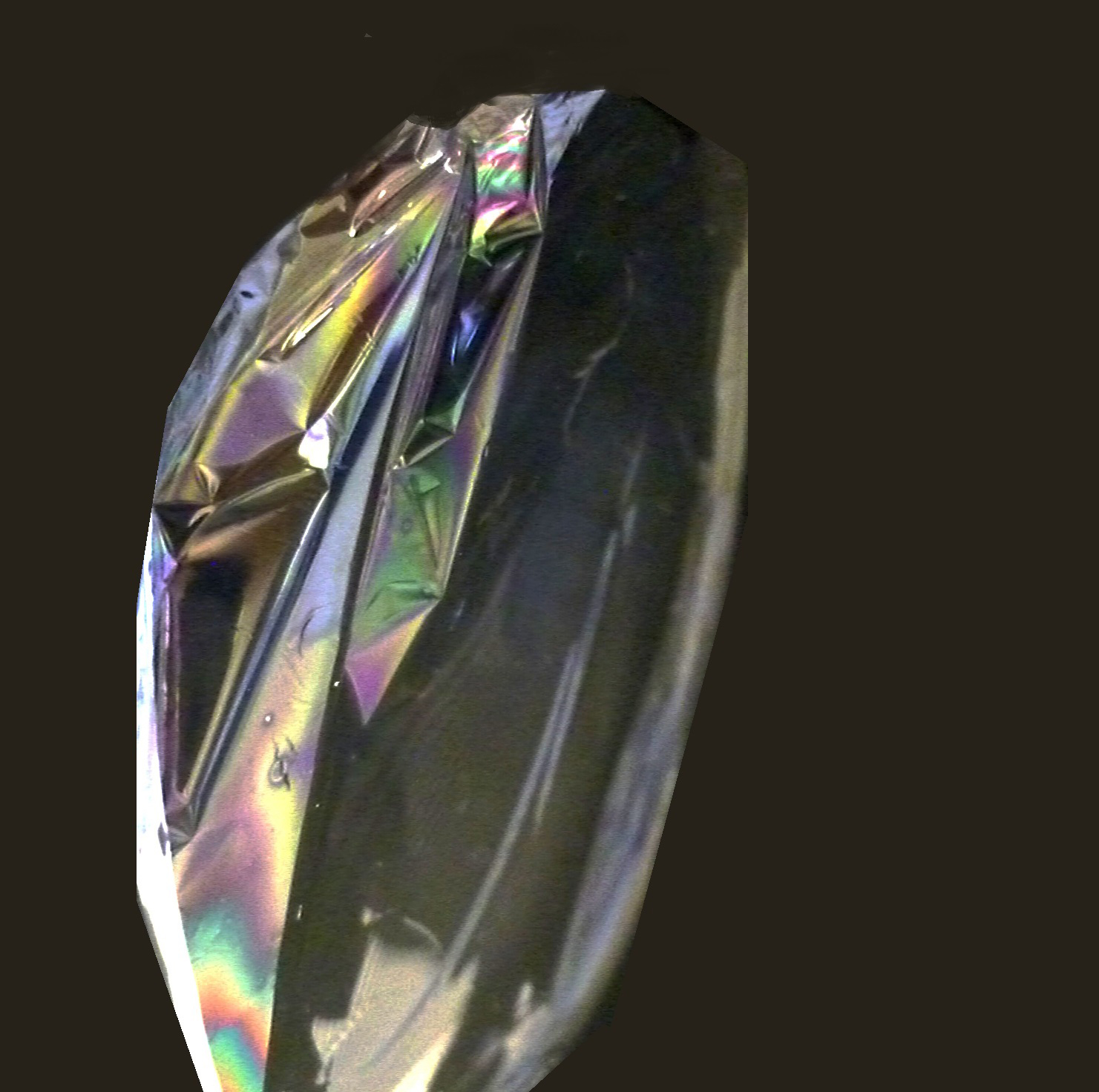

Water repellent textiles through modified chitosan

The second possible application is the functionalization of textiles, i.e. the finishing of textile fabrics with specific properties. “For example, we want to use the functional amino group to link hydrophobic molecules with the chitosan. Water-repellent properties can be achieved when applied to textiles,” elucidates Thomas Hahn. The chitosan serves as a matrix, fixed anchor point and crosslinker for the hydrophobic molecules. The regular repeating structure, besides the primary amine groups with their excellent reactivity, forms the basis for the use of chitosan in textile coatings.

Together with the German ChitoTex partners complemented by Knopf´s Sohn in the BMBF project Hydrofichi (Grant agree number 031B0341A), formulations are being developed that allow homogeneous hydrophobization of the surface after padding of the textile and temperature exposure. The main objective is to render textiles water-repellent for use in sports and leisure and thus the partial replacement of commonly used synthetic agents and textile auxiliaries.

Presentation at techtextil fair

At the techtextil fair from May 14‑17, 2019 in Frankfurt am Main, Fraunhofer IGB will be available for further information and discussions at the joint stand of the Fraunhofer Textile Alliance in Hall 3.0, Booth C67.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB