19 Fraunhofer Institutes demonstrate the feasibility of a bio-based circular economy

How Do We Want to Run Our Economy and Production?

The wastewater treatment plant is turned into a vegetable farm, bio-based substances recovered from waste are being utilized to prevent oxidative spoilage in food packaging or provide environmentally-friendly and safe water-repellent coatings on functional textiles. In the EVOBIO project coordinated by Fraunhofer IGB, 19 Fraunhofer Institutes are working on solutions for a sustainable economy by developing new concepts that utilize material flows in bioeconomy process cycles to produce optimized materials for innovative products.

From environmental pollution to climate change – the crises of our time are anthropogenic. The cost of agriculture designed for mass production is high and the careless use of coal, oil, and other fossil fuels is damaging. It is high time to answer the question of how we want to run our economy and production cycles without harming the environment, the climate, valuable ecosystems and, ultimately, people.

In the EVOBIO project, 19 Fraunhofer Institutes have combined their expertise and over a period of five months have developed concepts and modules for a new way of doing business. This is now demonstrated through the use of selected examples. "We want to rethink the industrial value chain, in which raw materials are processed into specific materials that can be used to manufacture products," says Dr. Markus Wolperdinger, director of Fraunhofer IGB. Together with Prof. Alexander Böker, director of Fraunhofer IAP, and Prof. Andrea Büttner, director of Fraunhofer IVV, he has driven forward the project as part of the Fraunhofer Strategic Research Field Bioeconomy. "By-products or residual materials should be avoided or – following nature's example – should be returned to the material and substance cycle without leaving any residues," says Wolperdinger.

Wastewater, Waste, and CO2 as Resources

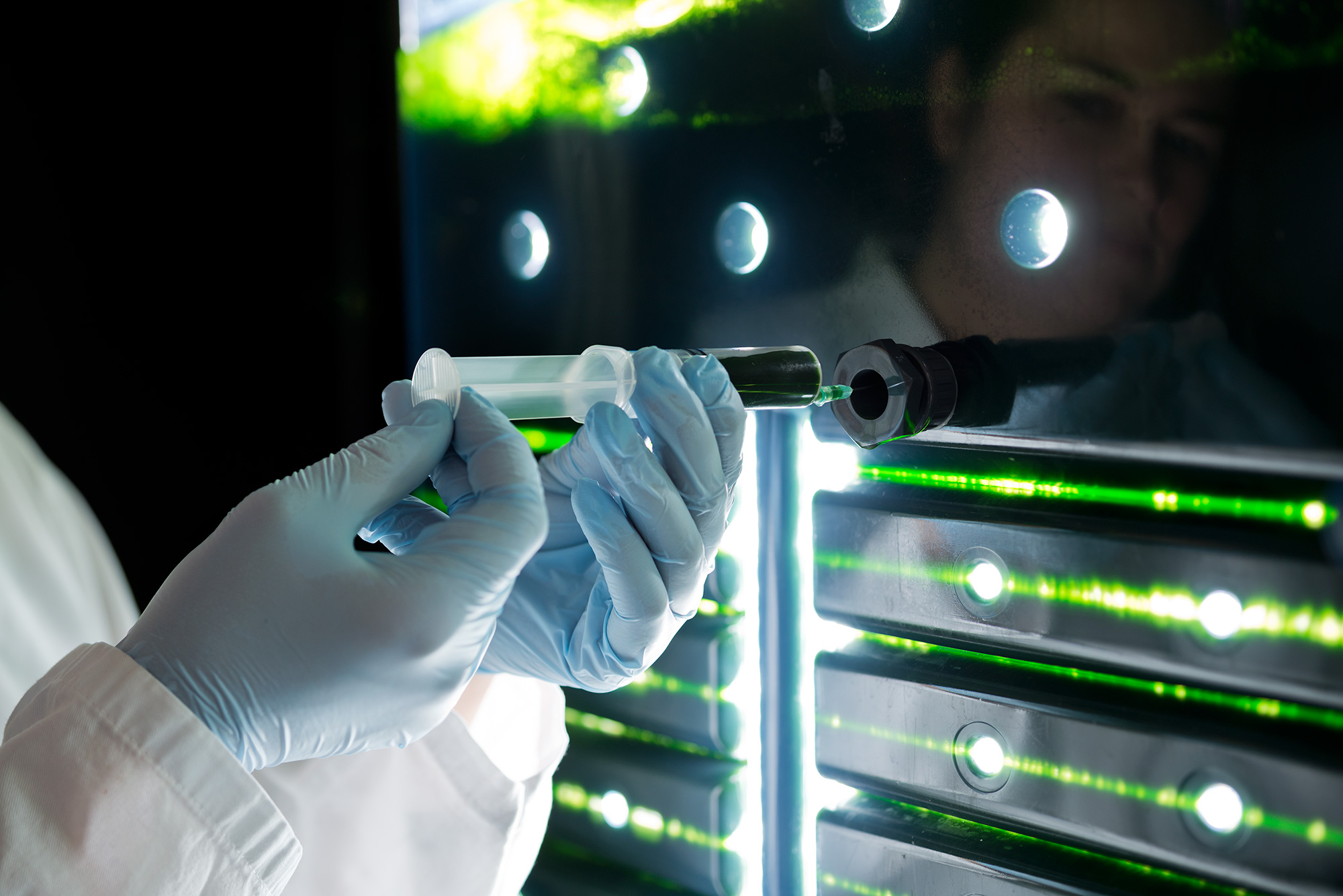

EVOBIO has already shown that this works: A wastewater treatment plant, for example, was expanded to become a central component of a regional recycling management system. The technical basis for this is known as high-load digestion. A pilot plant installed at the wastewater treatment plant in Ulm, Germany not only converts sewage sludge into biogas as a regenerative source of carbon and energy, but also provides additional material flows of sludge water and digestate. The EVOBIO partners use the nutrient-rich sludge water, for example, as a growth medium for unicellular microalgae. These microalgae produce polysaccharides that help plants defend themselves against fungal infections, such as powdery mildew, and thus can replace pesticides. Sludge water is similarly suitable for water-based vegetable cultivation: with its nutrients as fertilizer, lettuce grows from seedlings in hydroponic systems within a few weeks. The remaining solids after sludge dewatering, the digestate, are processed into valuable substances for material production in the next value-adding step. Using thermo-catalytic reforming, Fraunhofer scientists extract biochar, synthesis gas, and a bio-oil similar in composition to crude oil. New impedance-based inline sensors can continuously monitor the treated wastewater. They detect bacteria and simultaneously measure the concentrations of nutrient ions.

New Materials from Alternative Substance Streams

The Fraunhofer team is developing high-performance materials based on raw materials produced from wastewater or waste, as well as other biogenic raw materials. Some of these have new and additional functions and are intended to replace petrochemical materials in the future. One focus of the development work is bio-based polymer blends using novel additives and coating formulations. The researchers have a wide variety of applications in mind: Proteins produced from rapeseed extraction meal, for example, serve as oxygen barrier layers on food packaging. Protein-based nanofiber materials from various raw materials, such as kidney beans and rapeseed, are used to develop filter materials, coating agents, or wound dressing materials, and nanofiber nonwovens are spun from rapeseed protein.

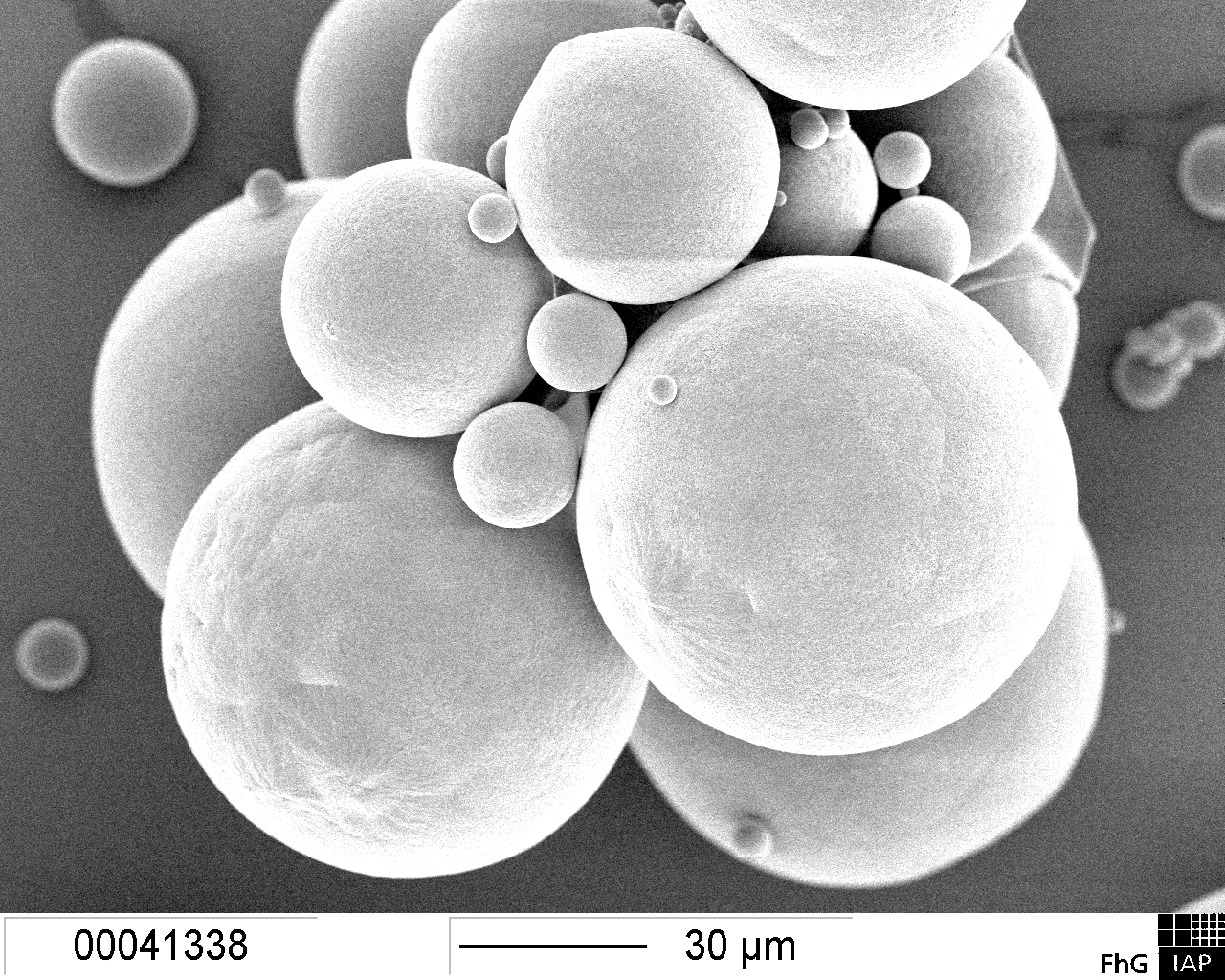

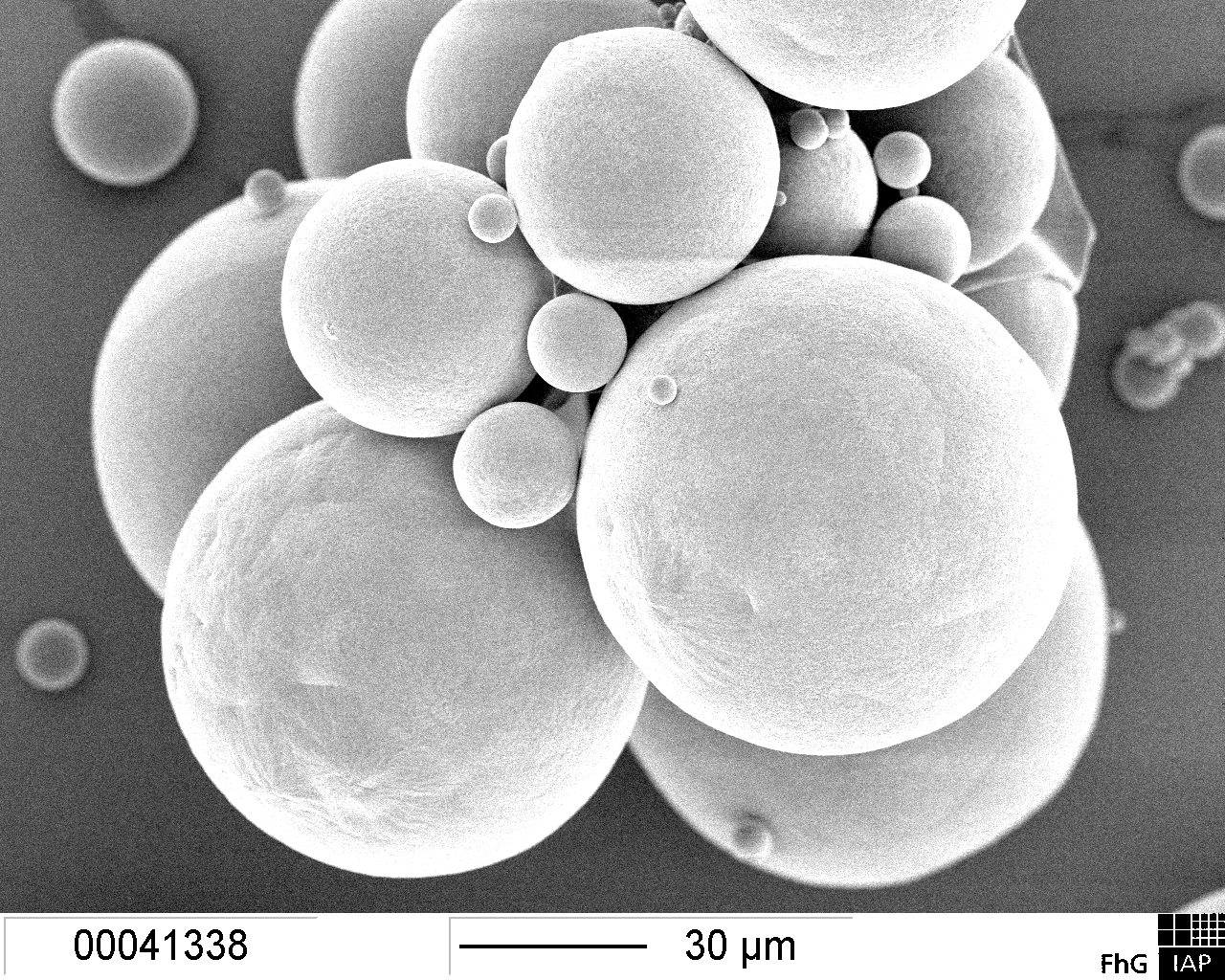

Bio-based and biogenic additives are also important for the green economy. Many natural substances, such as essential oils or enzymes, are known for their antibacterial, oxidative, and antioxidant or UV-absorbing effects. Direct integration of such substances into polymer materials and processes is therefore generally difficult, as the substances are often in liquid form, highly volatile, reactive, or unstable. In the EVOBIO project, biogenic substances are therefore microencapsulated so that they can be integrated into coatings or extruded polymer composites.

Optimized Products Made from Bio-based Materials

Especially in the packaging sector, bio-based polyethylene furanoate (PEF) is considered a promising replacement for petroleum-based polyethylene terephthalate (PET), which is the dominant material for fibers worldwide. As part of the project, the EVOBIO team is synthesizing PEF for fiber applications on a pilot scale using furan dicarboxylic acid as the starting material. The PEF obtained in this way can also be spun and post-treated using conventional melt spinning technology, which significantly simplifies its potential establishment on the market. The researchers are also developing foams made of shape memory polymer with bio-based fibers and particles.

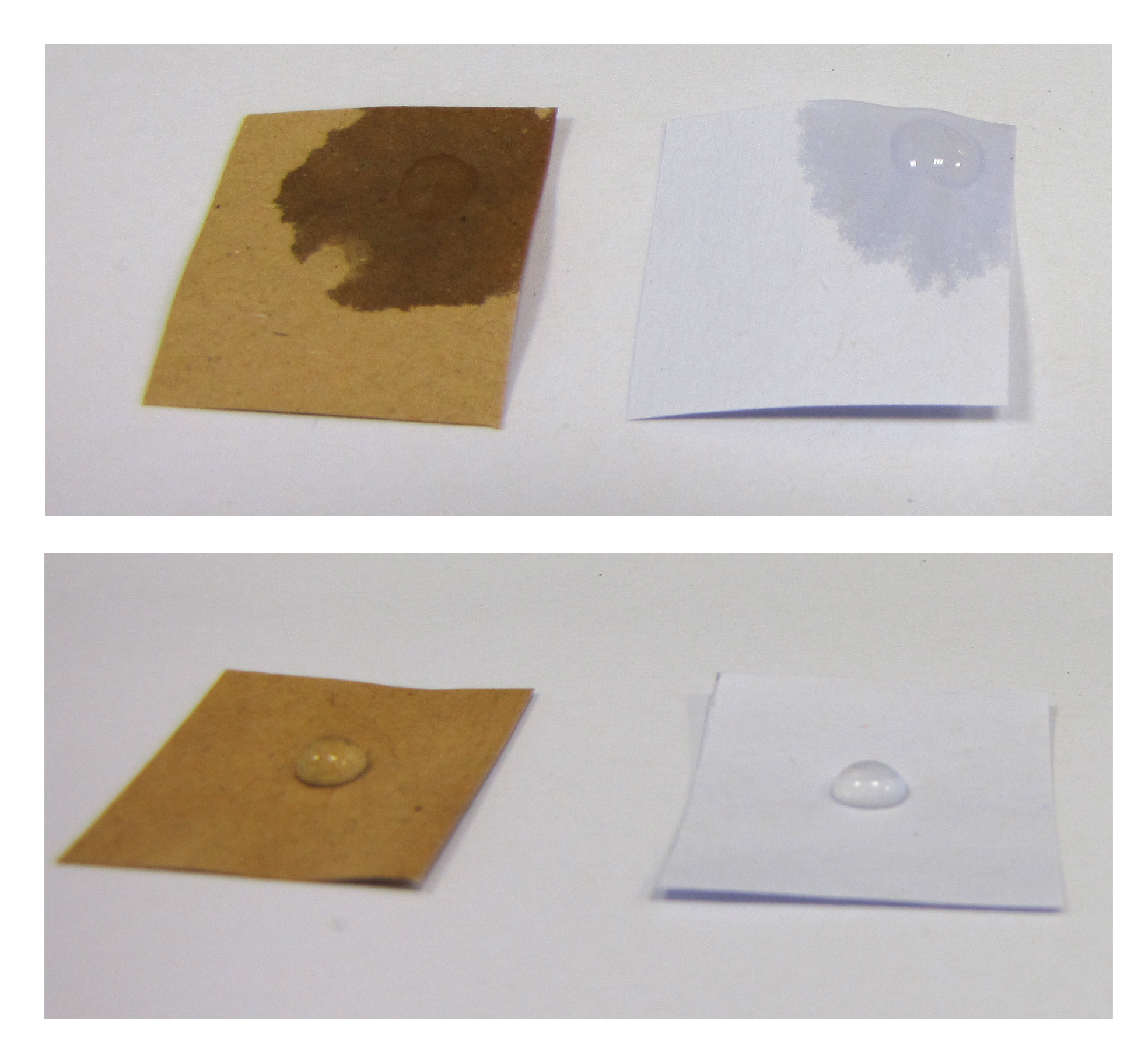

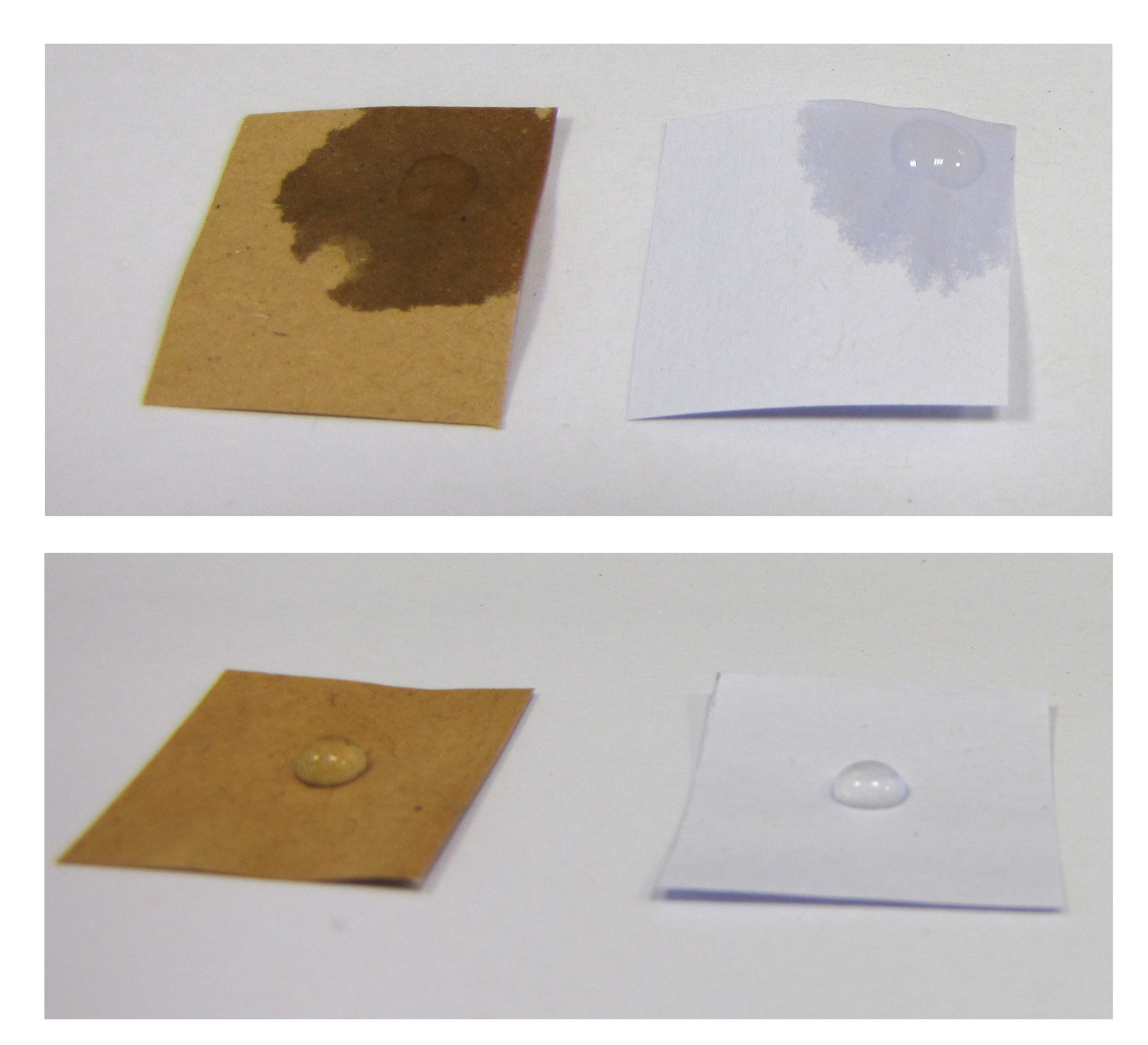

Protein-based materials with water-repellent properties are also being developed. In the future, they could replace halogenated hydrocarbons in the finishing of functional textiles. In combination with polyglucosamine from chitin, which comes from the shells and carapaces of crabs, shrimps, and prawns, applied to absorbent papers, the Fraunhofer researchers were able to demonstrate that functional layers with both water-repellent and water-vapor-permeable properties can be produced with bio-based and biodegradable materials.

Is the Market Ready?

The comprehensive approach pursued in the EVOBIO project requires that established value chains must be further developed into intercommunicating value networks. Are companies ready for this? What new business models are needed to turn wastewater treatment plants and operations that generate biogenic residues into producers of secondary raw materials and other usable materials? With a view to the utilization of the new bio-economy processes, the partners are evaluating their usefulness, feasibility, and transfer potential. By means of acceptance analyses, they are investigating whether companies consider the project results to be valuable. In addition, various business model scenarios are being developed and prioritized in terms of feasibility and economic viability.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB