Due to the great diversity of ingredients and the different cell wall characteristics of various species of microalgae, it is necessary to carry out selective processing of the biomass in order to effectively extract the high-quality nutrients. The objective of the joint research network “Microalgae – Integrated Use for Food and Feed” in the Baden-Württemberg Bioeconomy Research Program is to utilize various fractions as completely as possible, in interconnected and cascade use, in order to develop sustainable processes for the bioeconomy.

Processing of algae constituents

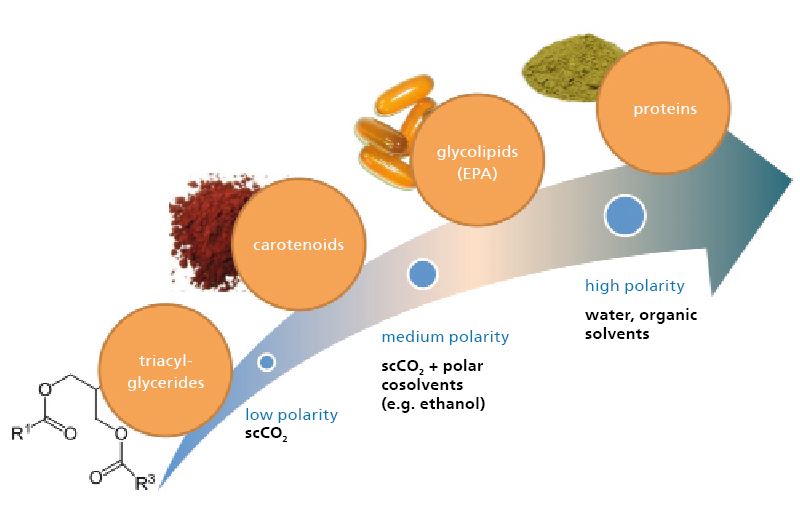

Special requirements apply to processing in the extraction of valuable compounds from algae biomass and the further use of the residual biomass, especially in cascade utilization. Basically the chemical character and the market specifications, for example the required degree of product purity, determine the processing technique. Further requirements are avoiding, as far as possible, an energy-intensive drying step as well as ensuring gentle extraction that both maintains the functionality and permits the extraction of further cell components.

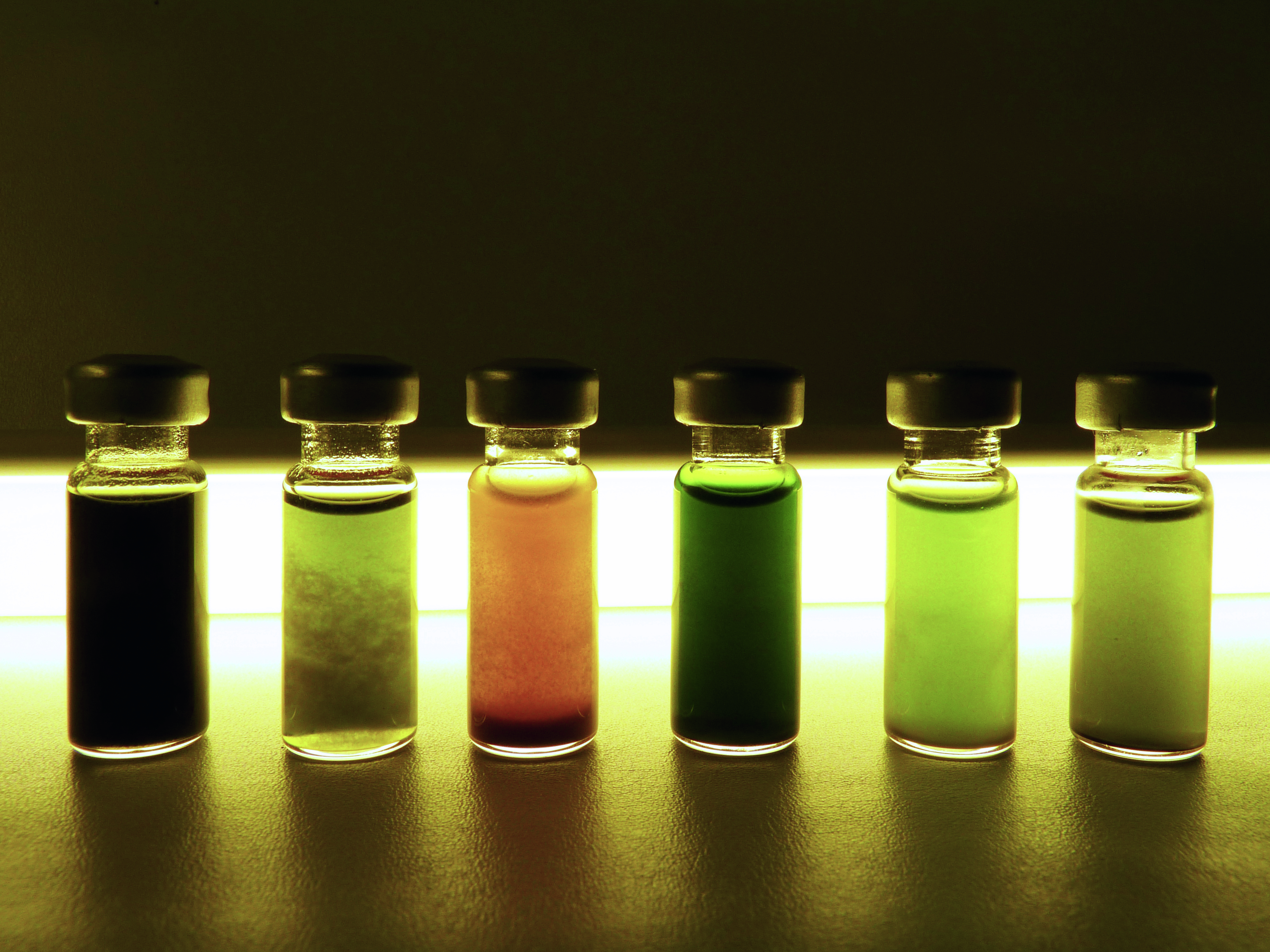

Working together with the partners in the research network, three strains of microalgae (Phaeodactylum tricornutum, Chlorella vulgaris and Nannochloropsis spec.) were selected that differ fundamentally in cell size, formation of the cell wall and biomass composition. By combining successive extraction processes in various sequences, the objective is to obtain in particular the principal fractions consisting of proteins, polar membrane lipids with omega-3 fatty acids as well as nonpolar triglycerides sequentially from the microalgae biomass – in addition to the high-value components such as carotenoids.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB