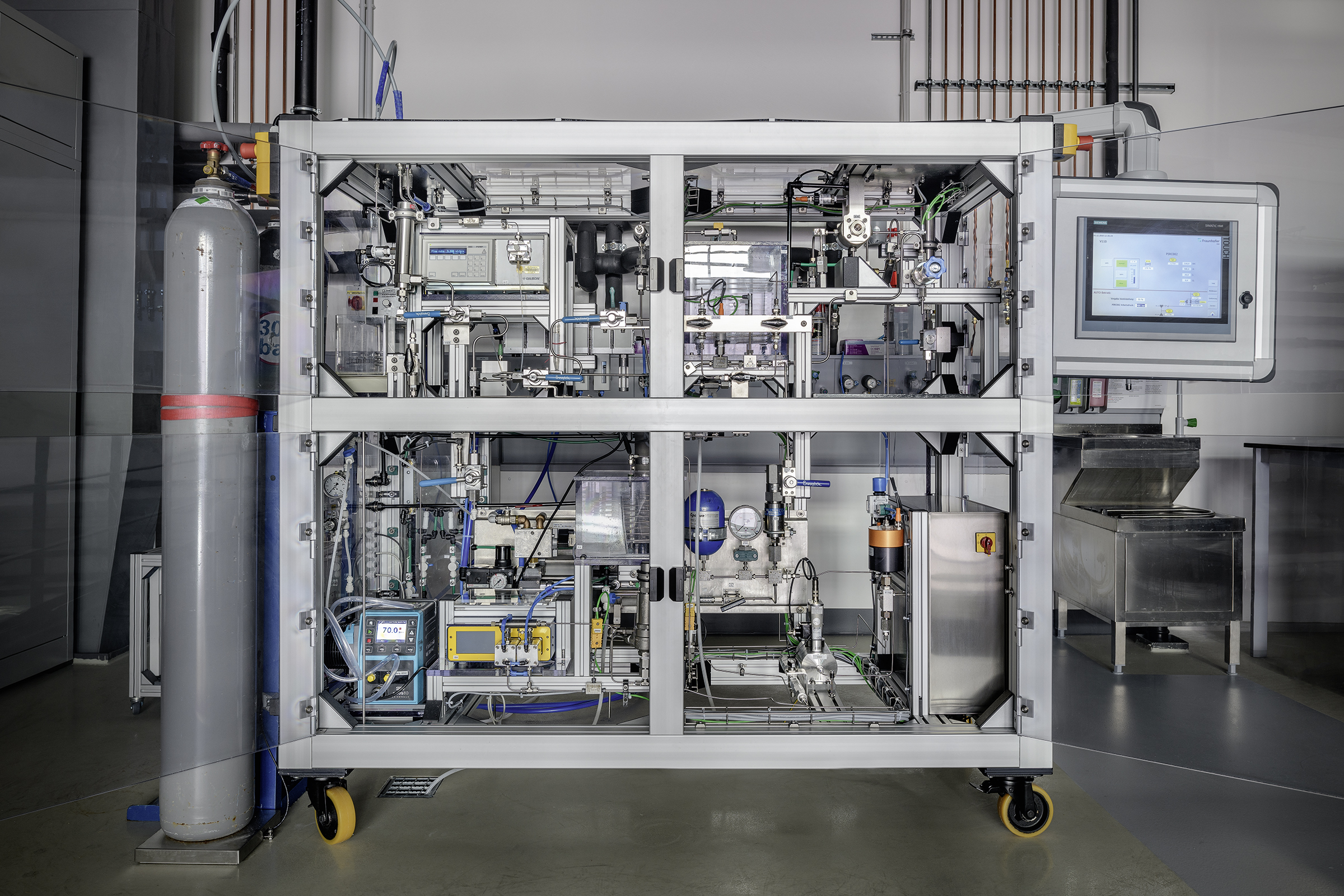

The processing of microbial biomass represents a significant cost factor in the production of biobased products. The aim of the EPI-CES project is to establish an integrated downstream process chain for microalgae ingredients and to demonstrate it in a laboratory plant consisting of cell disruption, extraction and separation. Among other processes, pressure change technology (PCT) for cell disruption with release of metabolites as well as pressurized liquid extraction (PLE) will be used.

EPI-CES – Efficient primary refining of microorganisms by integrating cell disruption, extraction and separation using microalgae as an example

New biorefinery concept for the extraction of functional ingredients from microalgae

In the production of biobased products, the downstream processing of microbial biomass represents a significant cost factor. Up to now, the process steps cell disruption and extraction/fractionation have been carried out separately in terms of time and space, which affects both the yield and the stability of the high-value ingredients.

The aim of the EPI-CES project is to integrate and intensify the downstream process chain (cell disruption, extraction and separation) of microalgae to enable competitive biomass processing and production of functional ingredients.

A process was developed at Fraunhofer IGB for the production of the microalgae Phaeodactylum tricornutum, which was then scaled up at Fraunhofer CBP. At the IGB, eicosapentaenoic acid (EPA), fucoxanthin and chrysolaminarin are recovered from the algal biomass by breaking down the cells using pressure change technology (PCT). By using inert process gases and low temperatures, this technology is particularly suitable for releasing sensitive intracellular metabolites and for preserving their functional properties.

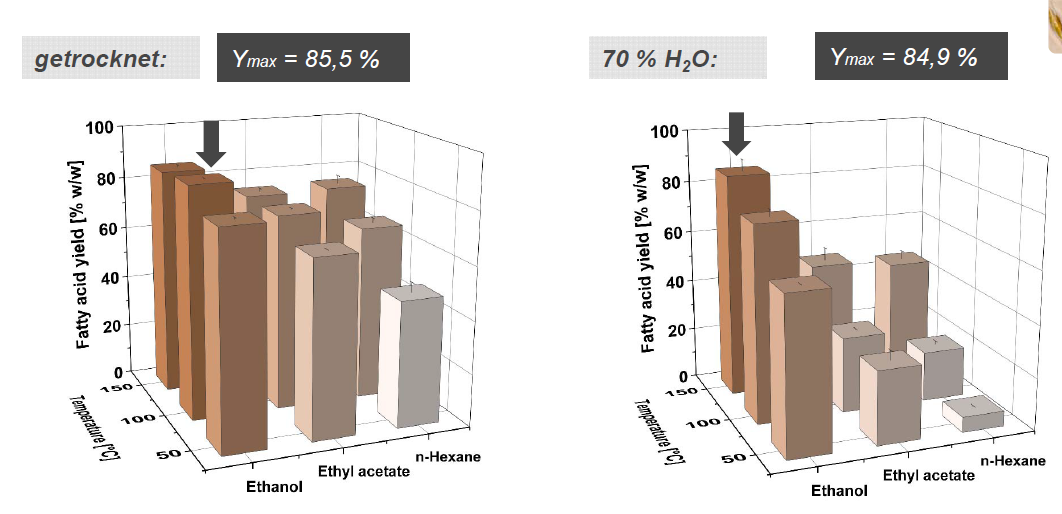

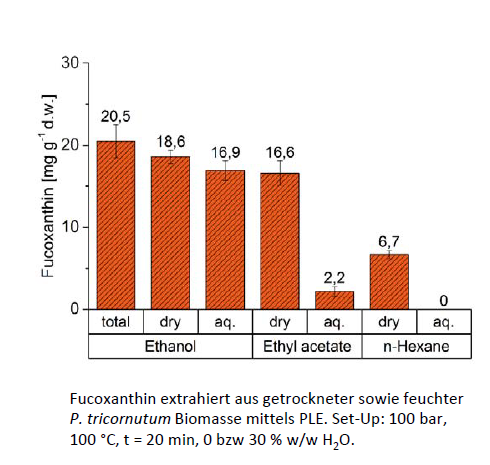

For the recovery of water-soluble chrysolaminarin, the aqueous phase is separated after cell disruption. The constituents fucoxanthin and EPA remaining in the wet biomass are isolated by pressurized liquid extraction (PLE). We were able to achieve the highest extraction (over 90 percent) for fucoxanthin and EPA using ethanol.

After optimization of the individual process steps, an integrated concept will be developed and demonstrated in a laboratory plant. The economic potential and the ecological added value of the process will be determined on the basis of a techno-economic evaluation and a comparison with existing technologies.

Project information

Project title

EPI-CES – Efficient primary refining of microorganisms by integrating cell disruption, extraction and separation using microalgae as an example

Poject duration

October 2018 – September 2021

Project partners

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, Stuttgart (Coordination)

- Fraunhofer Center for Chemical-Biotechnological Processes CBP, Leuna

Funding

We would like to thank the German Federal Ministry of Education and Research (BMBF) for funding the project »EPI-CES«.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB