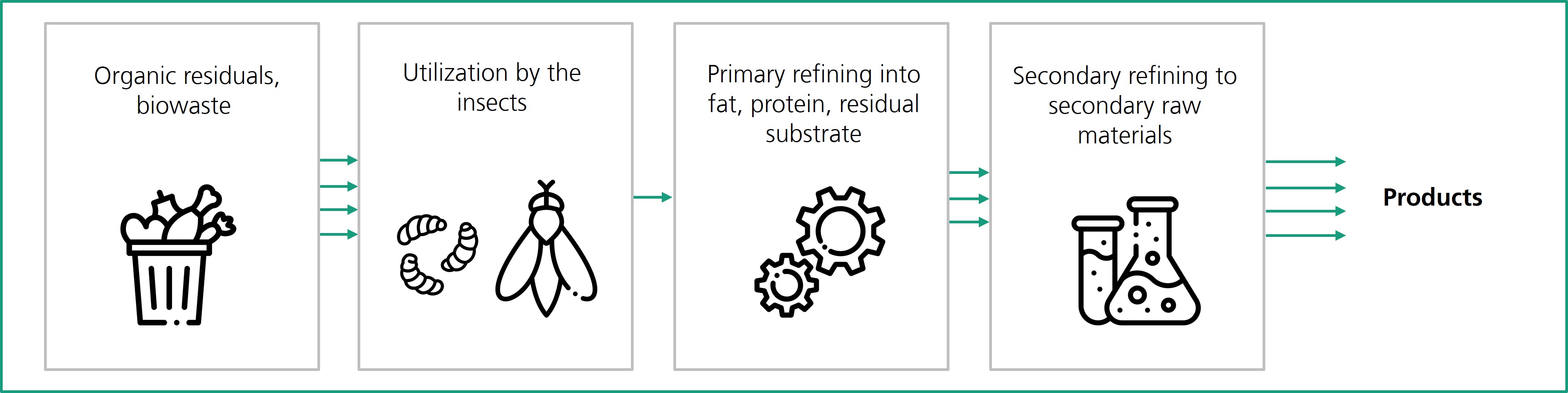

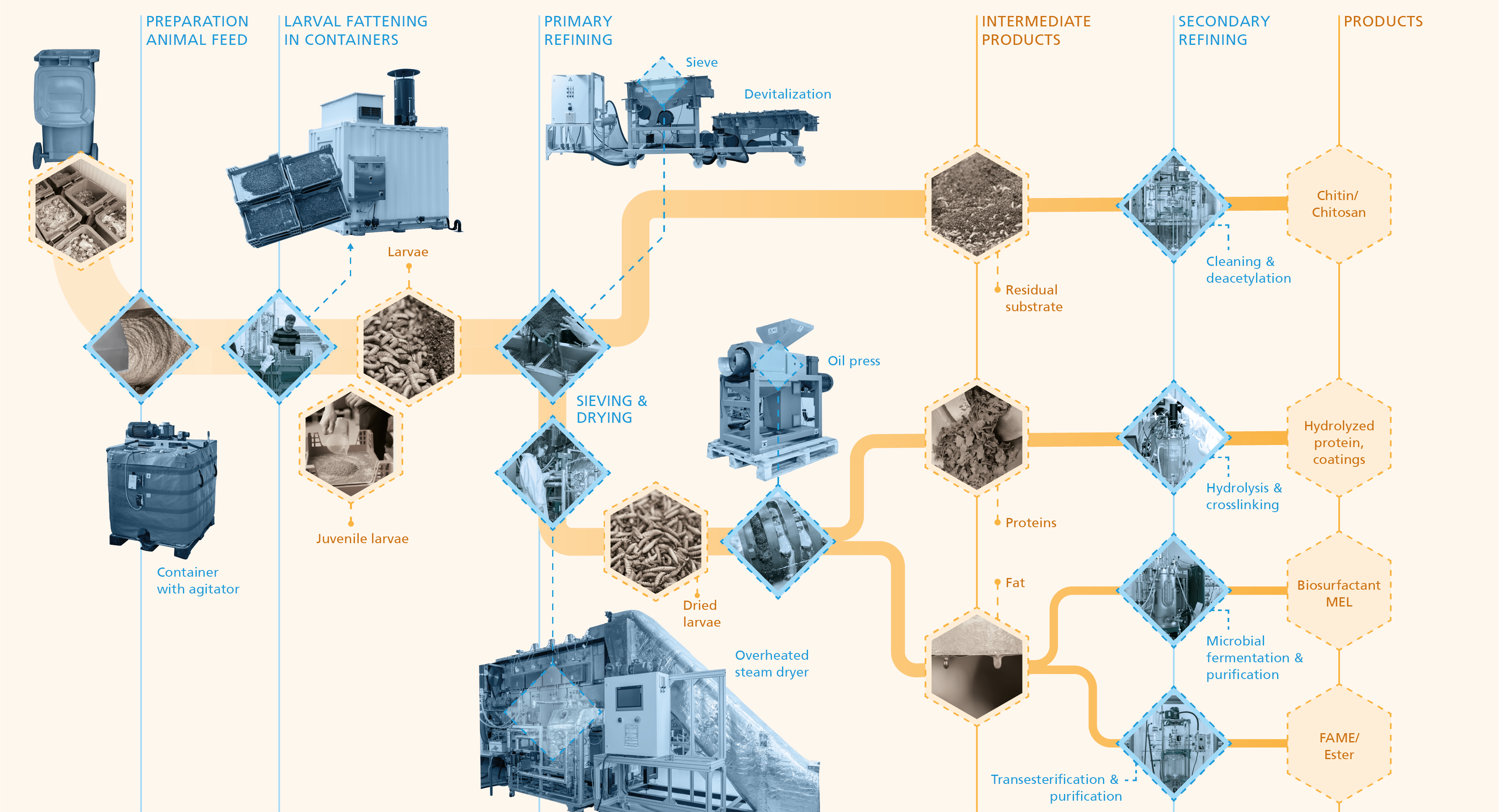

Waste processing, insect mast and primary refining

Initially, the waste and residual streams were processed in such a way that they could be efficiently utilized by the insect larvae. Challenges here included the seasonal variability of the organic waste bin, the unpacking of any packaged food returns, pesticide residues in fruit and vegetables from non-organic farming and discards (e.g. cutlery) from canteen waste. When preparing the feed, attention must also be paid to a balanced ratio of nutrients and water content. If there is too much water, the larvae can drown. Too much fat in the feed leads to phase formation and thus to poor and non-reproducible larval growth, and the separation of the larvae from the remaining substrate is also impaired later on.

In a specialized mast container designed for the insect biorefinery, young insect larvae were then cultivated with the processed waste and residual materials, converting them into biomass. Here it was crucial to ensure good ventilation and climate control so that the larvae had the same growth conditions throughout the mast container and that the substrate had a suitable residual moisture content for further processing at the end of the mast.

The insect larvae that have grown on the waste and residual materials were first separated from the residual substrate by sieving during primary refining. The larvae were then inactivated and dried. The subsequent pressing of the larvae initially enables coarse separation into a fat and a protein fraction. The raw fat could then be purified in further process steps and refined for further use. The protein fraction, the so-called press cake, was chemically degreased further in order to contain the purest possible protein.

In addition to the refined fat and protein fractions, several residual fractions remain from the insect biorefinery: unutilized substrate and excrement of the larvae (frass), chitin-containing larval skins and adult flies. These residual fractions can also be converted into valuable raw materials in the course of secondary refining.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB