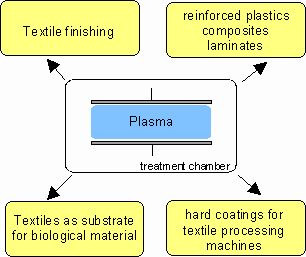

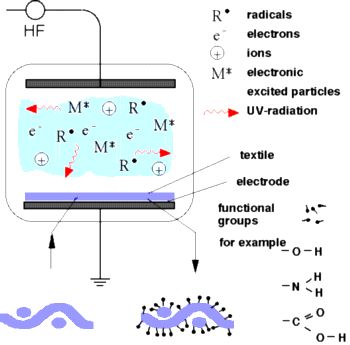

Due to increasing requirements on the finishing of textile fabrics, increasing use of technical textiles with synthetic fibers, as well as the market and society demand for textiles that have been processed by environmentally sound methods, new innovative production techniques are demanded. In this field, the plasma technology shows distinct advantages because it is environmentally friendly, and even surface properties of inert materials can be changed easily.

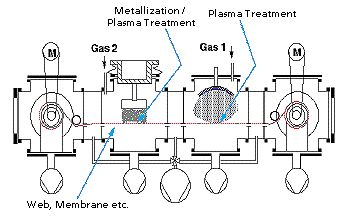

Plasma technology can be used not only for textile finishing, but also for the optimisation of textile machines, for example, with hard coatings.

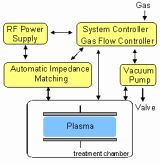

It has been known for at least 60 years that plasma could effect desirable changes in the surface properties of materials. However, the practical application of plasma required the development of commercially available, reliable, and large plasma systems. Such systems are now available (mostly in research laboratories) and the application of plasma to industrial problems has been increasing rapidly for the past 10 years.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB