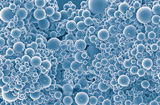

Our particle systems are given their biofunctions by encapsulating bioactive components in their core or by binding them on their surface. As particulate carrier material, we synthesize inorganic or organic particle cores with diameters ranging from 30 nm to 10 µm.

Production of biofunctional particles

Biodegradable particles

We encapsulate biological and medical factors such as growth factors or pharmaceutically active ingredients – depending on the solubility by means of water-in-oil-in-water or oil-in-water emulsions – in biodegradable particles, for example, of polylactid (PLA) or chitosan. Thus the active substances can be introduced into an aqueous environment and released there in a controlled manner. In doing so we customize the release speed of the encapsulated substances via the choice of the polymer and the degree of crosslinking of the particles.

Cell-mimetic particles

Particles that present proteins on their surface, for example signaling molecules, can to some extent act like a cell and activate other cells. For example, in the sol-gel processes we synthesized silicon oxide (SiOx) particle cores and first of all functionalized the particle surfaces with carboxyl groups, to which we bound the protein tumor necrosis factor-a (TNFa). These particles triggered signaling cascades in certain cells that otherwise only the TNF protein anchored in the membrane of cells can trigger. If we additionally equip the particle core with a fluorescent dye, the docking of the particles to cells and the cell death triggered by the TNF particles can be followed under the microscope.

Organic-inorganic composite materials

Inorganic particles such as HAP, TCP, SiO2 or TiO2 are dispersed in solutions of polymers, for example in PLA, PCL or hydrogels. Various dispersion processes are available (ultrasonic, ball mill) for this purpose. Subsequently these dispersions are processed e.g. by wet-spinning, electrospinning, knife coating or extrusion and are consolidated in this process. Crosslinking is possible by means of the functionalization of the internal interfaces of the composite materials. In this way the tensile strength of hydroxylapatite, for example, can be increased by dispersion in polylactic acid.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB