The aim in tissue engineering is to create functional tissues and organs in vitro and to use them as transplants or in vitro test systems. The generation of larger tissue constructs has been limited due to the lack of a proper nutrient supply throughout the tissue via a vascular system. As part of a Fraunhofer research project, a consortium of the five Fraunhofer Institutes IAP, IGB, ILT, IPA and IWM have joined together to accomplish the goal of developing an artificial blood vessel system.

BioRap

With rapid prototyping and “biologization” to artificial blood vessels

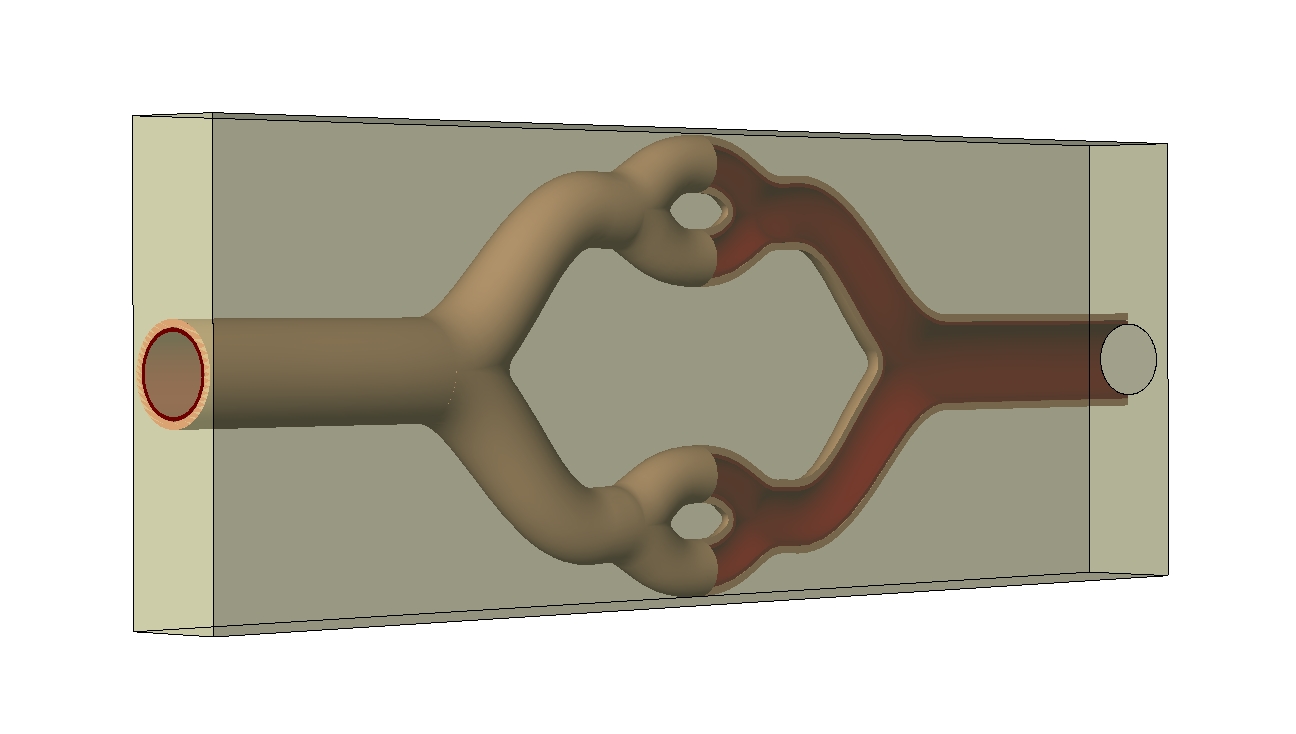

The combination of 3D inkjet printing technology and twophoton polymerization will enable the production of branched vessels smaller than 1 mm in diameter. The combination of the two technologies required the creation of special inks which were developed under the direction of the Fraunhofer IAP. They are based on a modular system utilizing different monomer and polymer components and can be customized for materials and their elastic properties. The focus of the Fraunhofer IGB is the biologization of synthetic tubular structures into biomimetic vascular systems. In order to do this, endothelial cells must be coated onto the synthetic structures in the same manner in which they coat blood vessels in the body. The first step towards this requires the biofunctionalization of the artificial material.

Biofunctionalization of materials

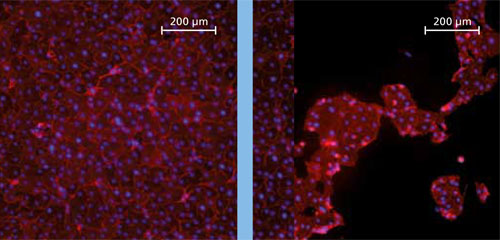

Synthetic surfaces are functionalized with modified biopolymers (such as heparin), growth factors (such as vascular endothelial growth factor, VEGF) and specific anchoring proteins for cells (e.g. the peptide sequence arginine-glycineaspartic acid, RGD), which allow the colonization of the endothelial cells into the materials. The formation of a confluent cell sheet on the synthetic surface can be achieved by the binding of modified heparin and RGD. Additionally, the thrombogenicity of the synthetic material may be significantly reduced.

As an alternative to the biofunctionalization step, the Fraunhofer IGB is developing hybrid materials from synthetic materials and biological components for a direct, one-step construction of biofunctional artificial vessels. For this purpose, we have modified biopolymers with polymerizable groups allowing their incorporation into the ink-formulation for the rapid-prototyping step. In doing so, the material contains covalently attached biomolecules, which improves an interaction with human cells.

Perspective: bioreactor for bio functional artificial blood vessels

The formation of a functional endothelium is essential for the biofunctionality of artificial blood vessels. Our goal is to completely cover the inner most layers of the tubes with endothelial cells. An essential step for the culture of functional endothelial cells is the replication of conditions in the body. For this purpose, the Fraunhofer IGB has developed a special bioreactor system in which the artificial vascular structures can be populated with endothelial cells through dynamic culture.

Project information

Project title

BioRap –Establishment of a bio-inspired vascular system for transplants via rapid prototyping utilizing an inkjet printer and multi-photon polymerization

Project duration

February 2009 – July 2012

Project partners

- Fraunhofer Institute for Applied Polymer Research IAP, Golm, Germany

- Fraunhofer Institute for Laser Technology ILT, Aachen, Germany

- Fraunhofer Institute for Manufacturing Engineering and Automation IPA, Stuttgart, Germany

- Fraunhofer Institute for Mechanics of Materials IWM, Freiburg, Germany

Funding

We would like to thank the Fraunhofer-Gesellschaft for financial support of the project ”Establishment of a bio-inspired vascular system for transplants via rapid prototyping utilizing an inkjet printer and multi-photon polymerization (BioRap)“ within the MAVO (market-driven prospective research) program.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB